Battery Management System at Fault in $900 Million EV Battery Recall

It’s instructive that a faulty battery management system (BMS) was at least partly the cause of Hyundai’s recent recall of 82,000 Kona model electric vehicles (EVs) to replace lithium-ion (Li-ion) battery packs that pose a risk of fire (Figure 1). Costing nearly a billion dollars, this is one of the largest ever automotive recalls.

Figure 1: Hyundai Motor Co. is replacing the batteries in about 82,000 Kona EVs and two other EVs sold globally due to potential fire risks. (Image source: Hyundai Motor Co.)

Figure 1: Hyundai Motor Co. is replacing the batteries in about 82,000 Kona EVs and two other EVs sold globally due to potential fire risks. (Image source: Hyundai Motor Co.)

As mentioned, it wasn’t entirely about the batteries. “The state-run Korea Automobile Testing & Research Institute's (KATRI) lab tests showed that neither the battery's separator nor misaligned battery cells caused the fire in the vehicles, while Hyundai's battery management system was not appropriately applied in the fast-charging system,” according to a report in the Korea Herald.

The report added; “The [Ministry of Land, Infrastructure and Transport] found some faulty battery cells made at LG’s plant in Nanjing from July 2017 to 2019 carry potential risks of fires,” and that in a previous recall, “Hyundai upgraded the BMS to limit the maximum charging rate to 90 percent,” but the recall was prompted when a vehicle that had received the software update caught fire.

Li-ion batteries are used in a wide variety of applications including mobile robots, electric bikes (e-bikes), drones, power tools, portable medical devices, and more, not just EVs. The recall by Hyundai points out the critical need for effective BMS designs, in addition to the use of high-quality Li-ion batteries.

Fortunately, designers have multiple choices for designing BMS systems, including evaluation boards and reference designs to speed the design process. Let’s take a look at several BMS solutions available for EVs and large mobile robots from Texas Instruments, for e-bikes and smaller mobile robots from Maxim Integrated, and drones, rovers, power tools, and portable medical devices from NXP Semiconductors.

BMS for up to 560 cells

The QEC-Q100 qualified and ASIL-D compliant BQ79616-Q1 from Texas Instruments enables autonomous cell balancing and internal temperature monitoring. In the case of an overtemperature condition, it supports automatic pause and resume balancing. The BQ79616-Q1 provides high accuracy cell voltage measurements in under 200 microseconds (μs) for six to sixteen cells.

To speed the development of BMS applications, Texas Instruments offers the BQ79616EVM-021 evaluation board (Figure 2). Up to 35 BQ79616-Q1 devices can be connected to support Li-ion battery packs for EVs with up to 560 cells.

Figure 2: Each BQ79616EVM can manage up to 16 Li-ion cells, and 35 BQ79616EVM modules can be stacked together. (Image source: Texas Instruments)

Figure 2: Each BQ79616EVM can manage up to 16 Li-ion cells, and 35 BQ79616EVM modules can be stacked together. (Image source: Texas Instruments)

E-bikes and smaller mobile robots

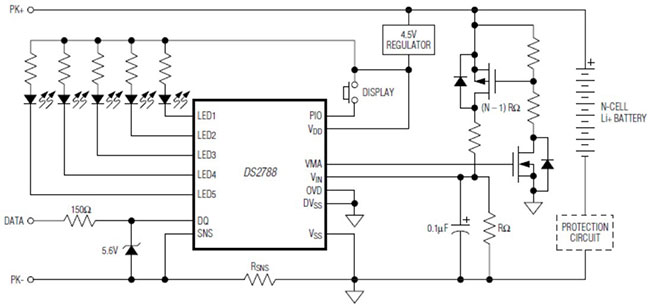

For designers of e-bikes, smaller mobile robots, and power tools, Maxim Integrated offers the DS2788E+ to monitor current, voltage, discharge rate, and temperature (Figure 3). It also estimates the available capacity for Li-ion and Li-polymer batteries. An on-chip EEPROM stores the cell characteristics and application parameters. Capacity estimation is reported as a percentage of full charge in milliampere hours (mAh). The DS2788E+ includes LED display drivers to simplify displaying the state of charge. To jump-start designs, Maxim offers the DS2788EVKIT+ DS2788 fuel gauge power management evaluation board.

Figure 3: The DS2788 includes LED display drivers to simplify displaying the state of charge for Li battery packs. (Image source: Maxim Integrated)

Figure 3: The DS2788 includes LED display drivers to simplify displaying the state of charge for Li battery packs. (Image source: Maxim Integrated)

BMS for 3 to 6 cells

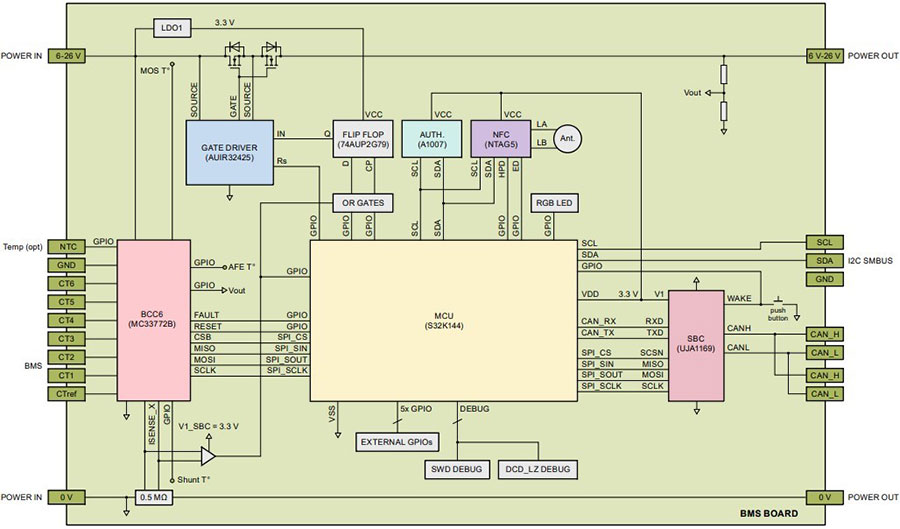

For designers of drones, rovers, scooters, power tools, and portable medical devices using 3 to 6 cells, NXP offers the RDDRONE-BMS772 BMS reference design (Figure 4), based on the MC33772B, a 6-channel Li-ion battery cell controller. The controller performs analog-to-digital conversion on differential cell voltages and currents to provide battery charge coulomb counting and battery temperature measurements. When used in drones, the reference design can communicate with a flight management unit (FMU) through UAVCAN and/or an SMBus.

Figure 4: The RDDRONE-BMS772 reference design can communicate with an FMU through UAVCAN and/or an SMBus. (Image source: NXP)

Figure 4: The RDDRONE-BMS772 reference design can communicate with an FMU through UAVCAN and/or an SMBus. (Image source: NXP)

The RDDRONE-BMS772 reference design features:

- Support for 3 to 6 cell battery stacks with voltages ranging from 6.0 to 26 volts

- Accuracy of ±5.0 millivolts (mV) when measuring stack and cell voltages

- Active cell balancing while the stack is charging

- Supports battery authentication

- Support for CAN, I2C, and NFC communication

- Includes a low leakage current deep sleep mode (for storage and transportation)

Conclusion

When batteries are mentioned in massive EV automotive recalls, many are quick to assume that it must have been the battery due to the chemicals and structures involved in their manufacturing. But as this particular case points out, that’s too simplistic. The importance of the synergistic relationship between the battery and the BMS cannot be overstated. In addition to high quality Li-ion batteries, designers need to be very careful with their BMS design choices, and take advantage of available evaluation boards and reference designs to test and verify those choices.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum