Applying a Holistic Approach to Integrated Factory Automation

If you recall the early days of manufacturing’s digitalization, the silo mentality prevailed. There was little or no information sharing between design and planning, machine programming, and production. Engineers would take printed CAD and bill of materials (BOM) output from the front office and manually program machine tools on the factory floor. Those same engineers would then solve production issues as they arose without ever feeding the problem and associated fix back to the product designers. The disconnect between design and manufacturing removed the option to refine a product to make it simpler, quicker, and less expensive to manufacture.

But things have changed. Today, connectivity is king of the modern factory (Figure 1). Industrial Ethernet networks link design, planning, programming, and production so that every part of the factory can share information with every other part and the world at large. The result is a free flow of information that enables engineers to optimize the assembly process to improve productivity and quality while creating minimal waste.

Figure 1: The connected factory enables engineers to rapidly update assembly machine programs to maximize quality and productivity. (Image source: Omron)

Figure 1: The connected factory enables engineers to rapidly update assembly machine programs to maximize quality and productivity. (Image source: Omron)

Not so fast

That factory-wide connectivity is a good thing is beyond argument. It’s also beyond argument that putting such a system in place is anything but trivial. Cost and complexity typically result in networks running non-interoperable software and wireless protocols that rely on controllers, sensors, programmable logic controllers (PLCs), and human-machine interfaces (HMIs) from various manufacturers. Such a situation means engineers spend much of their time implementing workarounds to ensure everything works together, at least until the next breakdown. The constant tinkering needed to keep things ticking along multiplies maintenance and upgrade costs.

There are some specialized commercial solutions that overcome interoperability and compatibility challenges. These products generally work well, but the downsides are added complexity and perpetuation of a piecemeal solution. An alternative is a holistic approach through a fully integrated automation platform from a single supplier, with network, component, and software elements designed to work harmoniously.

What’s a fully integrated automation platform?

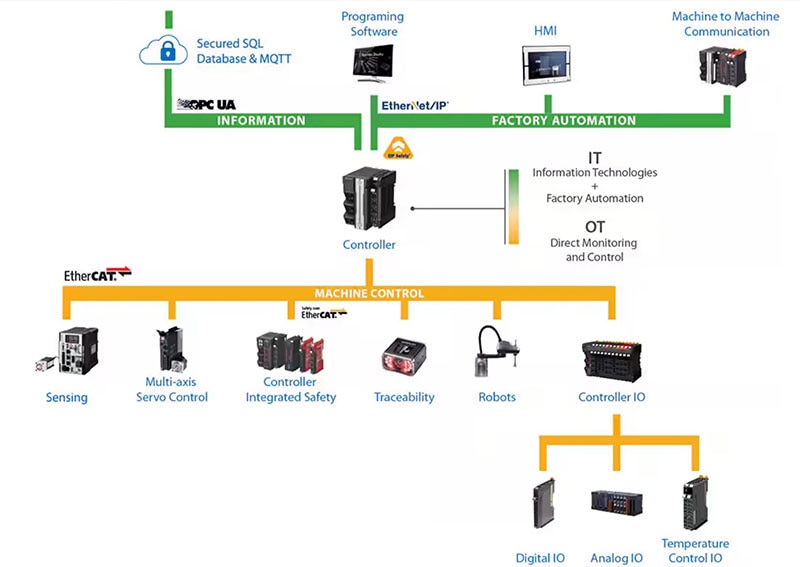

A “fully integrated automation platform” is the kind of phrase that marketers love to include in their brochures. But what exactly does it mean? Definitions vary depending on who you ask, but automation supplier Omron describes a network as tying together the manufacturing facility’s information technology (IT) and operational technology (OT) parts (Figure 2).

Figure 2 : A fully integrated automation platform for a manufacturing plant comprises IT and OT networks. (Image source: Omron)

Figure 2 : A fully integrated automation platform for a manufacturing plant comprises IT and OT networks. (Image source: Omron)

The IT section of the network comprises the front office, where design and production planning take place, and the factory automation part. Factory automation looks after machine programming, operator interfaces, and machine-to-machine (M2M) communication. The OT section of the integrated automation platform comprises factory and machine monitoring, sensors, robots, and machine control.

Omron’s Sysmac is one such platform. Sysmac simplifies factory-wide connectivity because it uses Industrial Ethernet connectivity (EtherNet/IP for IT and factory automation and EtherCAT for the OT network), a single machine automation controller, and shared supervisory software.

Automation controller at the heart of the platform

The critical link between the IT and OT networks is the machine automation controller (“controller”), which is an Industrial PC running Sysmac Machine Control software in Omron's solution. The controller provides synchronous control of all machine motion, safety, vision, robotics, sensing, and database connectivity in accordance with the manufacturing protocols determined by the IT system.

An example of a controller is the Omron NX102-1020. This controller can process information from the IT database without needing a gateway. It can also supervise machine safety and maintain production quality while at the same time providing high-speed, high-precision machine control. The unit is based on an Intel Core i7 microprocessor, which can execute basic instructions in as little as 0.37 nanoseconds (ns) and update commands to servos and stepper motors every 125 microseconds (µs). Sensors quickly feed machine position, displacement, and backlash information back to the controller. The result is smooth cam motion and high-precision movement of machine axes.

The NX102-1020 (Figure 3) features three industrial Ethernet ports (two EtherNet/IP and one EtherCAT), a CPU unit, and a power supply in a compact design measuring 66 millimeters (mm) wide. The controller conforms with IEC 61131-3 standards, which covers basic software architecture and programming languages of the control program in a PLC, and uses PLCopen Function Blocks for Motion Control.

Figure 3: The NX102-1020 controller features three Industrial Ethernet ports, a CPU unit, and a power supply in a compact form factor. (Image source: Omron)

Figure 3: The NX102-1020 controller features three Industrial Ethernet ports, a CPU unit, and a power supply in a compact form factor. (Image source: Omron)

A single software platform

Software, or rather several forms of software patched together to work as a whole, can be the Achilles’ heel of a factory automation platform. Keeping such a system maintained and running smoothly takes a lot of time and can prevent engineers from focusing on optimizing the production process.

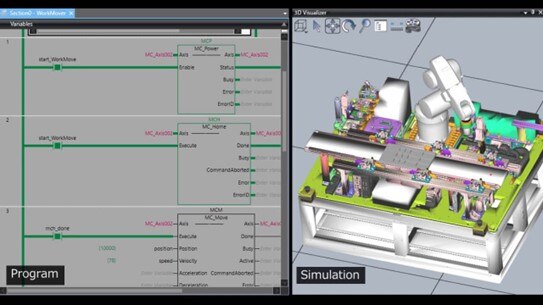

Omron’s solution addresses this challenge by using one software package to run its entire system, including programming the NX102-1020 controller. Called Sysmac Studio (Figure 4), the software is effectively an integrated development environment (IDE) that also includes a custom 3D motion simulation tool. Like the Omron controller, the IDE fully complies with the IEC 61131-3 standard. The IDE allows programming with variables, meaning the engineer doesn’t need to learn the internal memory map of the PLC. It also means programs can be reused.

Figure 4 : Sysmac Studio includes a custom 3D motion simulation tool allowing the engineer to check and refine a production process before implementation. (Image source: Omron)

Figure 4 : Sysmac Studio includes a custom 3D motion simulation tool allowing the engineer to check and refine a production process before implementation. (Image source: Omron)

Conclusion

The connected factory is the future of manufacturing, but getting the pieces together and running smoothly can be challenging. An alternative is a holistic approach through a fully integrated automation platform with network, component, and software parts sourced from a single supplier, designed to work seamlessly and allow the focus to be on optimizing the manufacturing process.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum