Common Challenges of High Power Pin-to-Socket

Are you having difficulty with pin-to-socket alignment when mating two rigid PCBs or busbars? Does your design call for a compact interconnect system that provides the necessary power while still maintaining low profiles? Or maybe you’re struggling with power efficiency as a component in your cost management efforts?

If you answered yes to one of these questions, then consider how a high-current interconnect system that offers a degree of float and provides solid electrical performance can help ease mating issues and reduce your costs. At DigiKey, the Molex Coeur High-Current Interconnect System is that system.

Coeur High-Current Interconnect System (Image source: Molex)

Coeur High-Current Interconnect System (Image source: Molex)

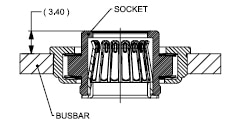

The Coeur High-Current Interconnect System delivers up to 200.0 A of current through three diameter sizes (3.40, 6.00 and 8.00 mm) and offers a wide range of configurations, connecting PCBs, busbars and cables. The Coeur system meets the demands of design applications by solving the following challenges you might face:

Challenge #1

Radial Pin-to-Socket Mating Misalignment

It is difficult to have perfect pin-to-socket alignment when mating two rigid PCBs or busbars. Consequently, there is a risk of damaging the contacts or PCB during mating. A degree of float is necessary in these situations to accommodate any possible misalignment. The unique Coeur float mechanism allows the entire core socket assembly to move within the float housing, offering the following advantages:

(Image source: Molex)

(Image source: Molex)

- No added deflection/stress on contact in float position

- Low mating forces

- No risk of resistance-increase due to high contact beam deflection

Challenge #2

Low-Profile Mated Height

The Coeur High-Current Interconnect System offers a mated profile as low as approximately 5.00 mm in all three sizes. It can do so without the compromise of having a large protrusion above or below the mated boards. Therefore, you do not have to sacrifice space or restrict air flow above and below the boards or busbars in order to achieve a low mated height. The Coeur system also offers pick-and-place compatibility to facilitate process automation, reducing manufacturing costs.

(Image source: Molex)

(Image source: Molex)

- Saves space above the PCB or busbar

- Enables automated SMT socket placement to PCB

- Allows for a time-efficient process

Challenge #3

High Current with Low Voltage Drop

Power efficiency is critical for cost management in large power-consuming operations such as data centers. The Coeur High-Current Interconnect System is designed with multiple contact beams per socket, allowing for solid electrical performance (low voltage drop). Molex’s t-rise and voltage drop data demonstrate that Coeur interconnects are a stable and reliable contact system that offers the following advantages:

(Image source: Molex)

(Image source: Molex)

- Offers design flexibility to meet a range of high-current applications

- Allows for power efficiency in large power-consuming operations

The DigiKey and Molex Advantage

For your next engineering design, choose the Coeur High-Power Interconnect System, available at DigiKey. This system provides reliable, cost-efficient and flexible design solutions for several manufacturing challenges. Molex’s Coeur system also delivers power efficiency and process automation that reduce cost and labor time for applications in several markets, including Data Centers, Industrial and Telecommunications/Networking. Consider DigiKey also for Molex’s Triton Grounding Straps and cable assemblies.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum