What Support Products Does It Take to Maximize the Impact of Using VFDs and VSDs? - Part 2

Contributed By DigiKey's North American Editors

2024-08-09

Part 1 of this article series looked at what to consider when selecting motor connection cables, output reactors, braking resistors, line reactors and line filters. Part 2 continues by looking at the differences between VSDs/VFDs and servo drives, reviewing uses for AC and DC rotary and linear servo motors, considering where soft start-stop units fit into industrial operations, and Looking at how DC converters are used to power peripherals like sensors, human-machine interfaces (HMIs), and safety devices.

Variable speed drives and variable frequency drives (VSDs/VFDs) are essential to maximizing industrial operations' efficiency and sustainability, but they’re not the only tools available. To get the ultimate performance, VSDs/VFDs often need to be supplemented by other devices like servo drives and motors, soft start-stop units, direct current (DC) converters, and direct current (DC) input uninterruptible power supplies (UPS) to arrive at an optimal industrial automation architecture.

AC and DC servo motors and drives are suited for various applications, from simple 1- or 2-axes tasks to complex tasks with 256 or more axes of motion. Servo motor-controlled actuators provide precise and repeatable movements for industrial machines and are available with rotary and linear motion configurations.

Constant speed applications like conveyors, pumps, and overhead cranes can often benefit from using soft start-stop units instead of VSDs/VFDs.

Depending on the application requirements, designers can select between redundant DC power supplies, a Class 2 power supply as defined in the U.S. National Electric Code (NEC), or a DC UPS to handle unpredictable mains power and improve system reliability.

This article begins with a look at the differences between VSDs/VFDs and servo drives, reviews uses for AC and DC rotary and linear servo motors, and considers where soft start-stop units fit into industrial operations. It continues by reviewing how DC converters are used to power peripherals like sensors, human-machine interfaces (HMIs), and safety devices. It examines when to use a redundant DC architecture or a DC UPS to power those devices and the choice between battery and supercapacitor energy storage. Representative devices from Schneider Electric, Omron, Lin Engineering, and Siemens are presented in each case.

Servo motor systems can complement VSDs/VFDs in industrial automation architectures. Servo motor systems are designed for complex and dynamic motion systems and can support precise positioning. Servo drives are used with permanent magnet motors and encoders for closed-loop control. They are designed to support rapid acceleration and deceleration and can support linear or non-linear motion profiles.

Many VSDs/VFDs use open-loop control to manage motor speed. They don’t support the precision or responsiveness available with servo motor systems. In addition, open-loop motor control means that VSDs/VFDs don’t necessarily compensate if the load changes or the motor stalls. While servo motor systems are used in highly dynamic applications, VSDs/VFDs are used in applications that maintain a constant speed, or relatively few speed changes, over a long period.

Servo motor systems tend to be smaller than VSD/VFD drives, with typical power levels from 40 to 5,000 W. They feature high speeds, up to 5,000 revolutions per minute (rpm), low noise, low vibration, and high torque. Servo motors are available in various frame sizes, up to 180 mm or larger. For example, the SBL40D1-04 from Lin Engineering is a 40 mm, 60 W brushless DC (BLDC) servo motor with a rated voltage of 36 VDC.

Servo motors are often paired with drives. Schneider Electric offers the LXM28AU07M3X drive and BCH2LF0733CA5C 5,000 rpm servo motor, both rated for 750 W (Figure 1). The drive features integrated CANopen and CANmotion communication interfaces and can operate with single-phase or three-phase power. The companion 80 mm motor is IP65 rated and can operate from -20°C to +40°C.

Figure 1: Matched 750 W servo drive and IP65-rated motor. (Image source: Schneider Electric)

Figure 1: Matched 750 W servo drive and IP65-rated motor. (Image source: Schneider Electric)

Linear and cartesian motion

Linear motion is used in various industrial processes, from coating materials and 3D printing to inspection systems, and is available in several embodiments. Some are based on rotary stepper motors, and other designs use linear motors. Rotary stepper motors produce linear motion using a threaded shaft. There are two basic designs, external-nut and internal-nut, sometimes called non-captive.

The nut is mounted on the threaded shaft in an external-nut linear actuator. The shaft is fixed on both ends. As the stepper motor rotates, the nut moves back and forth along the shaft, carrying the object (payload) to be moved. In a non-captive design, the payload is attached to the motor. The shaft is fixed at both ends, and the motor carrying the payload moves along the shaft.

Linear motion stages with high-efficiency iron-core linear motors, magnet tracks, and absolute encoder technology can provide repeatable sub-micron precision and 5G acceleration, moving up to 5 m/s for high-speed industrial applications. Unlike threaded shaft designs, linear motors can provide higher positioning accuracy and faster movement.

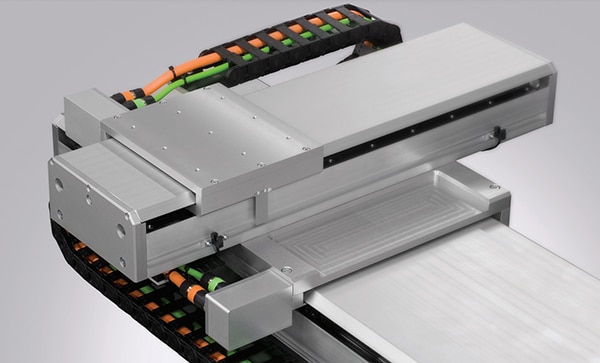

The mechanical parts of linear motion stages can be packaged in highly enclosed structures for environmental protection. Omron offers linear motion stages based on iron core motors ranging from 30 mm active magnet width and three coils to 110 mm active magnet width and 15 coils. They are rated to deliver from 48 Newtons (N) to 760 N of force.

The R88L-EA-AF-0303-0686 linear actuator motor is available in 230 V and 400 V models. It has a rated force of 48 N and a peak force of 105 N. It can be driven with the R88D-KN02H-ECT servo driver that includes EtherCAT communication for integration into industrial networks. Two linear motion stages can be stacked to provide motion in a cartesian coordinate system (Figure 2).

Figure 2: Two linear motor stages can be stacked to support cartesian motion. (Image source: Omron)

Figure 2: Two linear motor stages can be stacked to support cartesian motion. (Image source: Omron)

Soft start-stop units

While VFDs/VSDs and servo drives control motors' speed and torque while running, soft start-stop units limit current inrush when a motor is started to protect the motor and provide a smooth ramp up in speed and torque. They provide smooth ramp downs in speed as the motor is stopped. They also protect the mechanical components in the system from damaging torque spikes when starting or stopping.

A motor soft start-stop unit can benefit applications like conveyors, pumps, fans, overhead traveling cranes, and automatic doors that don’t need high levels of start-up torque and run at constant speeds. Controlled and predictable speed changes also improve operator safety.

Motor starting and stopping speeds are guided using solid-state devices like silicon-controlled rectifiers (SCRs) that control the voltage and the current to the motor. Once the motor is fully started, the SCRs are bypassed using a contactor to improve operational efficiency.

Soft start-stop units like the Alistart 22 family from Schneider Electric can handle a wide range of three-phase asynchronous motors from 4 kW to 400 kW. They include Class 10 motor overload and thermal protection, providing a fast-tripping time of 8 to 10 seconds. The power ratings of soft start-stop units often depend on the motor's operating voltage. For example, Schneider Electric’s ATS22D17S6U unit can handle motors rated for 3 hp with 208 V power, 5 hp with 230 V power, 10 hp with 460 V power, and 15 hp with 575 V power (Figure 3). It requires 110 VAC 50/60 Hz power for the control circuitry.

Figure 3: This soft start-stop unit can handle motors up to 15 hp. (Image source: DigiKey)

Figure 3: This soft start-stop unit can handle motors up to 15 hp. (Image source: DigiKey)

Redundant power

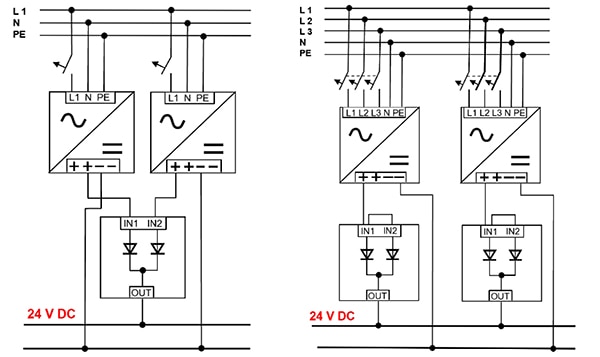

Industrial systems use 24 VDC power for various functions like sensors, HMIs, and safety devices. Basic redundant power can improve the reliability of industrial installations. Redundant power uses two power supplies connected in parallel to power a load where each power supply is sufficient to power the entire load should the other supply fail. When two power supplies are used, it’s called 1+1 redundancy. Both power supplies must fail for the system power to fail.

Using more power supplies in an N+1 configuration can increase the reliability of the overall power delivery system. A 3+1 redundant power architecture uses four power supplies, any three of which can power the entire load.

A redundancy module typically uses diode isolation to connect the power supplies to ensure that the failure of any one power supply does not affect the operation of the other power supplies. For applications that require even higher reliability, multiple redundancy modules can be employed to eliminate the possibility of a single point of failure (Figure 4). For example, Omron’s S8VK-C12024 AC/DC power supply can support 24 V loads up to 120 W. Two of those power supplies can be connected using the S8VK-R10 redundancy module to create a 120 W 1+1 redundant power system.

Figure 4: Using multiple redundancy modules (right) can eliminate the single point of failure and enhance reliability. (Image source: Siemens)

Figure 4: Using multiple redundancy modules (right) can eliminate the single point of failure and enhance reliability. (Image source: Siemens)

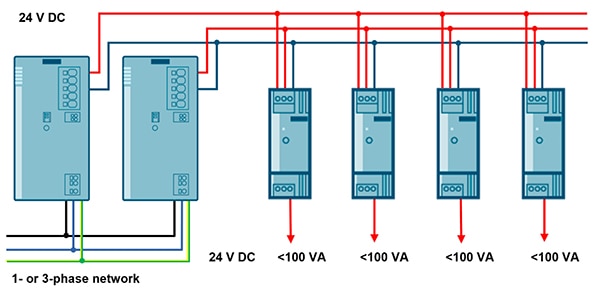

Class 2 and redundant

Class 2 power can be an important safety factor in industrial installations. As defined in the U.S. NEC, Class 2 power supplies have an output limited to less than 100 VA. Class 2 power is also required or recommended with some industrial devices outside of the U.S.

Limiting the power reduces the risks of electric shock and fire. As a result, Class 2 installations do not require the power cables to be routed through conduits or ducts, simplifying installation and reducing costs. In addition, simpler inspections are required for Class 2 installations, further reducing costs.

There are two ways to achieve a Class 2 power rating. Power supplies that internally limit the output power to under 100 VA are available. Or, a higher wattage power supply like the 480 W (24 VDC and 20 A) 6EP15663AA00 from Siemens can be used with redundancy modules like Siemens’ 6EP19622BA00 that limit the output power as well as providing redundancy for multiple loads (Figure 5).

Figure 5: 1+1 redundant power supplies (left) connected to four loads through Class 2 redundancy modules. (Image source: Siemens)

Figure 5: 1+1 redundant power supplies (left) connected to four loads through Class 2 redundancy modules. (Image source: Siemens)

Uninterruptible power

Redundant power can be useful, but it’s not enough for critical applications. When traceability and data collection are mandatory, safety is a concern, or uninterrupted operation is required, a UPS like the 6EP41363AB002AY0 SITOP UPS from Siemens will be needed. This UPS provides a 24 VDC output and can deliver up to 20 A.

One of the key questions when selecting a UPS is the energy storage technology. Ultracapacitors, also called double-layer capacitors, are suited for short-term backup power needs like saving process data and orderly shutdown of industrial PCs and other devices. They have a long life and can provide up to 20 kilowatt seconds (kWs) of backup power. For example, Siemens’ model 6EP19332EC41 capacitor energy storage unit can provide up to 2.5 kWs of backup power.

Lead-acid and various lithium-ion chemistries can be useful for longer backup power needs, which take up to several hours for critical communications or process operations (Figure 6). Basic DC UPS battery modules with up to 38 Ah of storage are available. Multiple battery modules can be used to provide backup times of several hours. The 6EP19356MD31 DC UPS battery module from Siemens uses maintenance-free sealed lead-acid batteries to provide up to 15 A with a storage capacity of 2.5 Ah.

Figure 6: Ultracapacitors (UPS5005 and UPS501S) can provide short-term backup power (left), while batteries (UPS16090 and BAT1600) can support much longer backup power operation (right). (Image source: Siemens)

Figure 6: Ultracapacitors (UPS5005 and UPS501S) can provide short-term backup power (left), while batteries (UPS16090 and BAT1600) can support much longer backup power operation (right). (Image source: Siemens)

Conclusion

VSDs/VFDs are often considered to be the workhorses of industrial automation. However, a comprehensive industrial automation architecture requires more, including servo drives, motors, and soft start-stop units. Industrial automation system designers also have numerous DC power architectures to select from when optimizing uptime and reliability.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.