Using Hydrostatic Level Sensors to Improve the Efficiency of Fresh Water Processing

Contributed By DigiKey's North American Editors

2024-10-23

Clean, fresh water is vital. Drinking water processing plants are found almost everywhere. To operate efficiently, those plants need to monitor the available water level in wells, storage tanks, rivers, reservoirs, and other areas.

Depending on the application and operating conditions, water levels can be monitored using mechanical devices like floats or solid-state devices like hydrostatic level sensors. Some technologies are more suited for point-level applications to monitor specific level thresholds and prevent spills. In contrast, others are suited for continuous level measurements in process control and inventory management systems.

This article begins with an overview of point-level and continuous-level monitoring applications. It then presents the operating principles of hydrostatic level sensors and reviews some uses of those sensors in drinking water processing plants.

It briefly looks at how the U.S. Environmental Protection Agency (EPA) keeps track of freshwater consumption using an “abstraction register,” It then reviews some available hydrostatic level sensors from Endress+Hauser. It closes with application suggestions when integrating sensors into critical infrastructure installations like drinking water processing facilities.

Float-level sensors are simple mechanical devices. The float rises and falls along with the level of the water. That motion opens and closes a mechanical switch that indicates when a specific water level has been passed. These sensors are often used to prevent tanks from getting too full and spilling water or getting too low and damaging pumps or other equipment.

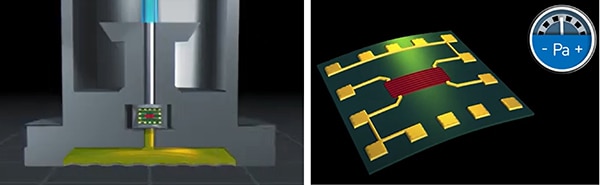

Hydrostatic level sensors provide a continuous measurement of the water level. They are commonly used in storage and processing tanks and vessels in freshwater processing plants. As the vessel fills or drains, the weight of the water above the hydrostatic level sensor changes, and the sensor produces a height-dependent output (Figure 1). That makes them especially useful for process control applications.

Figure 1: Float sensors move up and down (left) and can monitor specific levels in a tank, while hydrostatic sensors are stationary and provide continuous level monitoring (right). (Image source: Endress+ Hauser)

Figure 1: Float sensors move up and down (left) and can monitor specific levels in a tank, while hydrostatic sensors are stationary and provide continuous level monitoring (right). (Image source: Endress+ Hauser)

Hydrostatic level sensors measure the pressure of the water column above the diaphragm on the bottom of the sensor. An incompressible hydraulic oil transmits the pressure from the diaphragm to the sensor mechanism. The surface interface between the hydraulic oil and the water is relatively large, and the pressure is focused on a smaller column that reaches the sensor mechanism. The sensing mechanism consists of a Wheatstone bridge that changes resistance as the substrate is deflected (Figure 2).

Figure 2: Internal structure of a typical hydrostatic level sensor (left) and a representation of the Wheatstone bridge sensing mechanism being deflected (right). (Image source: Endress+ Hauser)

Figure 2: Internal structure of a typical hydrostatic level sensor (left) and a representation of the Wheatstone bridge sensing mechanism being deflected (right). (Image source: Endress+ Hauser)

Hydrostatic level sensors combine high reliability with very low installation costs. Their applications range from freshwater processing plants, where they ensure efficient operation, to monitoring local water ecosystems to ensure long-term water availability.

Freshwater processing

Water abstraction (water withdrawal, extraction, and intake) is the first step in delivering drinking water. It’s the process of taking water from any source. The amount of available water is closely monitored using devices like hydrostatic level sensors.

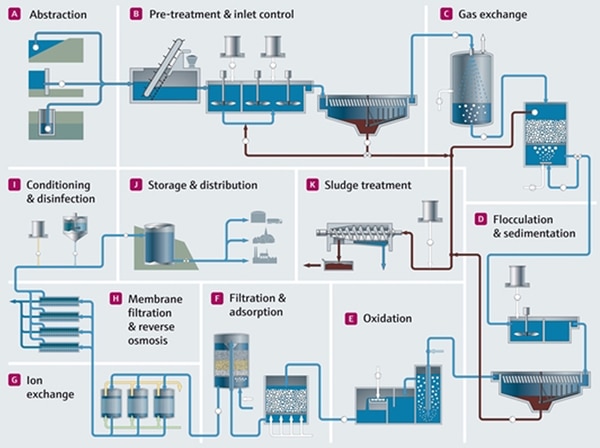

The rest of the freshwater processing details vary based on local regulations, but monitoring water levels is needed throughout the plant. Some common steps include (Figure 3):

- Coagulation is implemented by adding chemicals with a positive charge to the water to neutralize the negative charge of dirt and other dissolved particles.

- Flocculation involves a second chemical process where the coagulated particles form larger particles called flocs.

- Sedimentation is where the flocs settle to the bottom of the water, and the sludge is removed.

- Filtration is where various filters remove remaining dissolved particles and germs.

- Disinfection uses chlorine or chloramine to kill parasites, bacteria, viruses, and germs.

- Storage and distribution. Freshwater processing is a continuous process, but in most cities, water usage peaks in the morning and evening, requiring large storage facilities to match the availability of fresh water to the demand.

Figure 3: Potable water treatment can include many processes that must be monitored closely to ensure water quality and compliance with legal regulations. (Image source: Endress+Hauser)

Figure 3: Potable water treatment can include many processes that must be monitored closely to ensure water quality and compliance with legal regulations. (Image source: Endress+Hauser)

Abstraction register

Adequate water availability is necessary to ensure efficient freshwater processing. Environmental legislation controls raw water abstraction from natural sources to avoid damage to the local water balance.

In Europe, maintaining adequate water levels and flows is dictated by the Water Framework Directive, which focuses on the quantitative and qualitative management of natural water resources. In the U.S., the EPA has similar goals and closely monitors water abstraction.

The EPA collects information about the amount of water abstraction, together with information about water discharges, to assess the risk of over-abstraction. The data is reported in an annual abstraction register. Hydrostatic level sensors are important tools for monitoring local water ecosystems' health.

Hydrostatic level sensors

Hydrostatic level sensors are highly versatile devices. Typical applications include:

- Monitoring levels in rivers, lakes, gauging stations, and reservoirs

- Ensuring drinking water availability in water towers and storage tanks

- Measuring water level in wells

The compact 22 mm diameter of Endress+Hauser Waterpilot FMX11 submersible hydrostatic level sensors makes them easy to integrate. These sensors provide a 4 to 20 mA output signal compatible with data loggers, panel meters, programmable logic controllers (PLCs), and other process control equipment.

Waterpilot FMX11 hydrostatic level sensors have several drinking water certifications, including National Sanitation Foundation 61 (NSF-61) in the U.S., Attestation de Conformité Sanitaire (ACS) in France, and TZW:DVGW - Technologiezentrum Wasser in Germany.

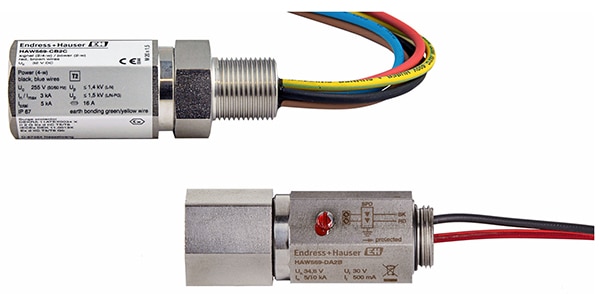

The housing is made of 316 alloy stainless steel and is approved for drinking water applications by the Food and Drug Administration (FDA). The shielded extension cable includes an atmosphere pressure compensation tube with a Teflon filter in an abrasion- and ultraviolet (UV) light-resistant thermoplastic elastomer (TPE) jacket. TPE and Teflon are also FDA-approved for drinking water applications (Figure 4).

Figure 4: Waterpilot hydrostatic level sensors have several international certifications for drinking water applications and are made using FDA-approved materials. (Image source: DigiKey)

Figure 4: Waterpilot hydrostatic level sensors have several international certifications for drinking water applications and are made using FDA-approved materials. (Image source: DigiKey)

General specifications:

- Operating temperature range of -10°C to +70°C

- IP68 protection

- Accuracy of ≤ ±0.35% for sensor measuring range ≥ 400mbar

- Accuracy of ≤ ±0.50% for sensor measuring range < 400mbar

- cULus certification

Available models:

- FMX11-CA11DS06 with a sensing range of 0 to 0.2 bar (6.7 ft of water column) and a 6 m cable

- FMX11-CA11FS10 with a sensing range of 0 to 0.4 bar (13.4 ft of water column) and a 10 m cable

- FMX11-CA11GS20 with a sensing range of 0 to 0.6 bar (20.1 ft of water column) and a 10 m cable

- FMX11-CA11HS20 with a sensing range of 0 to 1 bar (33.5 ft of water column) and a 20 m cable

- FMX11-CA11KS30 with a sensing range of 0 to 2 bar (66.9 ft of water column) and a 30 m cable

Maximizing water processing plant availability

Drinking water processing plants are critical infrastructure and require high levels of reliability. Waterpilot FMX11 sensors are tested per the electromagnetic compatibility (EMC) guidelines of EN 1000-4-5 / IEC 61000-4-5, which defines the requirements and methods for testing the ability to withstand power surges.

However, basic EMC testing only covers surges up to 2 kV on main power lines or 1 kV on signal lines. That can be insufficient for critical infrastructure where even indirect lightning or switching operations can result in surges up to 10 kV within microseconds.

Endress+Hauser recommends the use of surge arresters to ensure plant availability. Surge arresters are available and designed for DIN rail mounting in control cabinets and for direct mounting in a field housing:

- HAW562 surge arresters like the HAW562-AAD to protect power and communication lines in control cabinets

- HAW569 surge arresters for process field instrumentation like the HAW569-CB2C for power supply and signal cables and the HAW569-DA2B, for signal cables (Figure 5)

Figure 5: HAW569-CB2C for power and signal cables (top) and HAW569-DA2B for signal cables (bottom). (Image source: Endress+Hauser)

Figure 5: HAW569-CB2C for power and signal cables (top) and HAW569-DA2B for signal cables (bottom). (Image source: Endress+Hauser)

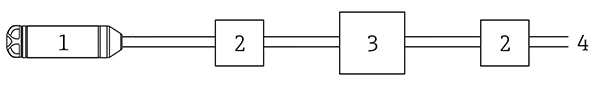

The recommended installation for maximum availability includes (Figure 6):

- Waterpilot FMX11 hydrostatic level sensor

- HAW surge arresters

- Display and evaluation unit with an input for a 4 to 20 mA sensor signal

- Power supply

Figure 6: Waterpilot FMX installation block diagram showing the positions of the two surge arresters (2). (Image source: Endress+ Hauser)

Figure 6: Waterpilot FMX installation block diagram showing the positions of the two surge arresters (2). (Image source: Endress+ Hauser)

The power supply voltage range is 8 VDC to 28 VDC, and current consumption is a maximum of 22 mA and a minimum of 2 mA. When used outdoors, the power supply should be housed in an IP66/IP67-rated terminal box. A circuit breaker that meets the requirements of IEC 61010 is highly recommended.

Waterpilot FMX11 hydrostatic level sensors have integrated reverse polarity protection and will not be damaged if the power cables are connected improperly. In the event of a reverse polarity connection, the device is not operational.

Safety integrity levels and explosive atmospheres

Hydrostatic level sensors also need to operate safely, even in the presence of explosive atmospheres. IEC 61508 defines safety integrity levels (SILs), and IEC 61511 is an application-specific adaptation of IEC 61508 for the process industry. HAW569 units are designed for use in field instrumentation and meet SIL2 requirements. HAW562 surge arresters are intended for use in less hazardous applications in equipment cabinets and are optionally available with SIL2.

The situation is similar to that used in explosive (Ex) atmospheres. HAW562 surge arresters are optionally available with Ex intrinsically safe approvals. Two common Ex certifications are Ex ia and Ex d.

Ex ia certification delivers intrinsically safe protection that ensures the maximum internal energy of the device and its wiring remains below the energy level required to cause ignition, even in the event of a fault. It’s intended for use in areas where an explosive gas mixture is present for extended periods or continuously and poses a significant hazard.

Ex d certified devices are designed to withstand an internal explosion without sustaining damage. These devices are intended for use in critical areas where an explosive gas mixture will likely occur during normal operation, presenting an intermittent hazardous condition.

HAW569 units designed to protect signal cables are optionally available with Ex ia approval, while Ex d approval is an option on those designed for the simultaneous protection of signal and power cables. HAW562 surge arresters are also available with optional Ex intrinsically safe approvals.

Conclusion

There are several applications for hydrostatic level sensors, including process control and inventory management in drinking water processing plants, as well as monitoring water sources like wells, rivers, lakes, and reservoirs to ensure water availability and sustainability. Drinking water processing plants are critical infrastructure and must be adequately protected to ensure continuous operation.

Waterpilot FMX11 hydrostatic level sensors are made using FDA-approved materials for drinking water applications and have several related international approvals. Endress+Hauser also recommends using surge arresters and offers models with SIL2 performance and Ex ia and Ex d certifications for Waterpilot FMX11 sensors.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.