How to Measure the Flow of Water to Improve Treatment Effectiveness and Efficiency

Contributed By DigiKey's North American Editors

2024-10-15

Monitoring and measuring water flow and volume is necessary for improving the efficiency and sustainability of power and energy plants, agriculture and mining operations, industrial and municipal water and wastewater treatment facilities, food and beverage processing, and similar operations.

There are several tools water system designers can turn to for quantifying available water and its flow. These tools minimize or eliminate direct contact with the water to maintain its state of purity. Electromagnetic flow (mag flow) meters provide a non-contact way to quantify flowing water. Water level in storage tanks can be measured using non-contact sensors like ultrasonic and radar-based designs. A third alternative is provided by sealed hydrostatic pressure level measurement sensors that are certified for drinking water applications.

This article reviews the operation and benefits of using mag flow meters and hydrostatic pressure sensors and compares the operation and applications for non-contact level sensors like ultrasonic and radar-based designs from Endress+Hauser. It then discusses how a data manager can record, display, and monitor operations and how IO-Link can quickly and efficiently stitch together a complete water monitoring system using a food and beverage processing line as an application example.

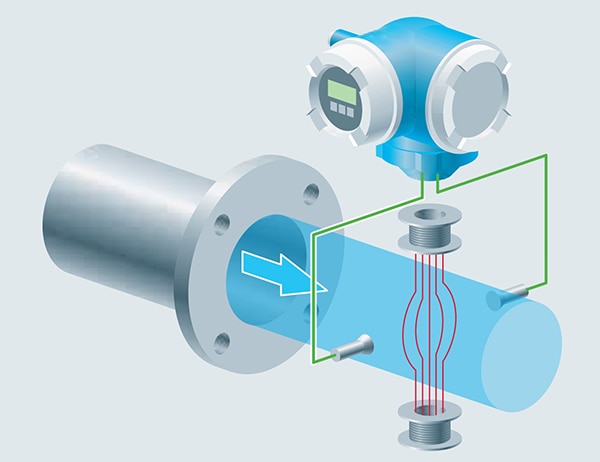

Faraday’s law of induction describes the operating principle of transformers, inductors, generators, and mag flow sensors. In a mag flow meter, electrically charged particles in the fluid being measured flow through a magnetic field created by two field coils, and a voltage is induced. The induced voltage is measured with two measuring electrodes (Figure 1).

Figure 1: In a mag flow meter, electrically charged particles in a liquid (blue arrow) flow between two field coils (red lines), and probes measure the induced voltage (green lines). (Image source: Endress+Hauser)

Figure 1: In a mag flow meter, electrically charged particles in a liquid (blue arrow) flow between two field coils (red lines), and probes measure the induced voltage (green lines). (Image source: Endress+Hauser)

The induced voltage is directly proportional to the velocity and volume of the flow. A pulsed direct current (DC) voltage generates the magnetic field. By alternating the polarity of the DC voltage, a stable zero point is established that makes flow measurements insensitive to low conductivity or inhomogeneous liquids.

Picomag DMA50 series mag flow meters are suited for a range of applications. The 1.4" TFT color display with backlight rotates automatically depending on the orientation and flow direction, simplifying installation. These meters can simultaneously measure flow, temperature, and conductivity. Flow measurement accuracy of ±0.5% can be realized over a wide range of flow rates.

The model DMA20-AAACA1 features a measuring range of 0.1 to 50 liters per minute (l/min) and a maximum pressure of 232 pounds per square inch (psi). It has a ¾” connection and an operating temperature range of -10°C to 60°C. Like all Picomag DMA50 series mag flow meters, it features IO-Link connectivity. Bluetooth is enabled via Endress+Hauser’s SmartBlue app, which simplifies and speeds operation, maintenance, and commissioning, even in challenging locations (Figure 2).

Figure 2: Example of a Picomag DMA50 series mag flow meter measuring flow (l/min) and conductivity (µS/cm). (Image source: Endress+Hauser)

Figure 2: Example of a Picomag DMA50 series mag flow meter measuring flow (l/min) and conductivity (µS/cm). (Image source: Endress+Hauser)

Model DMA20-AAACA1 has fluoroelastomer (FKM) O-rings that resist chemicals and excessive thermal conditions and support clean-in-place (CIP) and sterilization-in-place (SIP) automated processes used to clean and sterilize machinery, vessels, or pipes without disassembly.

Other models like DMA50-AAABA1 have ethylene propylene diene (EPDM) O-rings that resist ozone, sunlight, and weathering. Typical applications for Picomag mag flow meters include:

- Industrial ovens that are cooled using water flowing through multiple cooling lines

- Double jacket food processing systems that must measure the flow of heating and cooling water

- Cleaning containers like bottles and pasteurization processes benefit from monitoring the water temperature, supply, and drainage to maximize the efficient use of water

Ultrasonic vs. radar ToF level sensing

Ultrasonic and radar level sensors implement time of flight (ToF) measurements based on the speed of sound and light, respectively. Ultrasonic waves are reflected by the change in density between the air and the material's surface to be measured. Radar sensors, sometimes called free-space radar, emit microwaves reflected based on the shift from a low dielectric (low εr) medium like air to a higher dielectric material.

In applications like pump controls and level alarms, the Prosonic FMU30 series ultrasonic level sensors are designed for non-contact level measurement of fluids, including drinking and wastewater, pastes, and coarse bulk materials. Since it’s a non-contact technology, these sensors have minimal service needs. They are insensitive to the material’s dielectric constant and density or the surrounding humidity.

The measurement range of FMU30 sensors depends on the size of the sensor. They are offered in two sizes: 1½" sensors like the FMU30-AAHEAAGGF have a range of 5 m in fluids and 2 m in bulk materials, while 2" sensors have a range of 8 m in fluids and 3.5 m in bulk materials.

The FMU30 sensors have an operating temperature range of -20°C to +60°C. They use the ToF principle to measure distance. However, the speed of sound (and, therefore, the ToF) varies with temperature. FMU30 ultrasonic sensors have an integrated temperature sensor and automatically compensate for temperature changes to ensure accurate and repeatable measurements.

Radar level sensors

The Micropilot FMR10 series radar level sensors are optimized for use with materials with an εr of at least 4. They are suited for level measurements in storage tanks, open basins, pump shafts, canal systems, and similar applications. The hermetically sealed wiring prevents water ingress (Figure 3). They feature Bluetooth connectivity to speed commissioning using smartphones and tablet computers. Other features and specifications include:

- Frequency, K-band (about 26 GHz)

- Measuring range up to 12 m

- Accuracy of up to ±5 mm

- Process pressure from -1 bar to 3 bar (-14 psi to 43 psi)

- Process temperature from -40°C to +60°C

Figure 3: Hermetically sealed radar level sensor with a range of up to 12 m. (Image source: DigiKey)

Figure 3: Hermetically sealed radar level sensor with a range of up to 12 m. (Image source: DigiKey)

Hydrostatic level measurements

Monitoring freshwater availability in rivers, lakes, reservoirs, water towers, and wells can be important to effective water management. In those applications, water management system designers can turn to hydrostatic level measuring devices like the FMX11 hydrostatic probes that are certified for drinking water applications (Figure 4). FMX11 features and specifications include:

- Compact size with a 22 mm (0.87”) diameter makes these probes suitable for applications like boreholes and small-diameter stilling wells

- Operating temperature range of -10°C to +70°C

- Measuring range of 0 bar to 2 bar, 20 m H20, and 0 psi to 30 psi, depending on the model; Model FMX11-CA11FS10 can measure up to 0.6 bars (8.7 psi)

- Accuracy up to ±0.35%

- Drinking water approvals include French Attestation De Conformite Sanitaire (ACS), U.S.

- NSF/ANSI 61 and two German certifications, Kunststoff-Trinkwasser (KTW) and Deutscher Verein des Gas und Wasserfaches (DVGW)

- Analog 4 to 20 mA communication

Figure 4: Hydrostatic sensors like this are approved for use with drinking water. (Image source: DigiKey)

Figure 4: Hydrostatic sensors like this are approved for use with drinking water. (Image source: DigiKey)

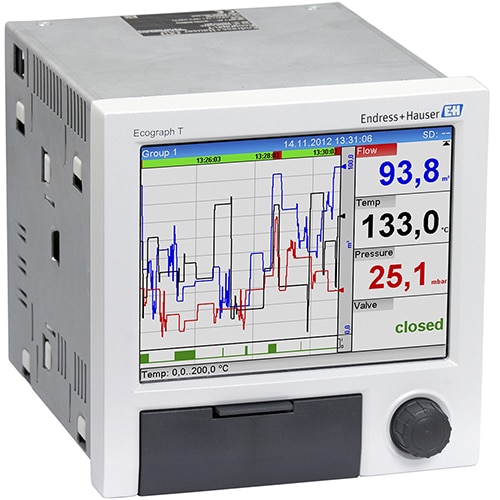

Managing data

Regardless of the parameters being monitored — flow, temperature, level, or something else —and the technology being used, the resulting data must be captured and displayed in a format supporting process management. System designers can turn to the Ecograph T RSG35 universal data manager that records, displays, and monitors analog or digital input signals. In addition, the measured values are securely saved, and the limit values can be monitored.

The standard version comes without analog data inputs. Some models come with up to three optional input cards that can be added, each with four analog universal inputs for a total of four, eight, or 12 analog inputs. For example, model RSG35-C2A has eight universal analog inputs, an RJ45 jack to facilitate Ethernet connections and Internet access, and a USB connector for peripherals and data transfers. Like all models, the RSG35-C2A includes six digital inputs.

The integrated web server in Ecograph T data managers supports remote configuration and visualization. The Essential Version of the Field Data Manager software is also included and can be used to save data to a secure SQL database stored in internal memory or on a separate SD card for analysis. The 5.7" TFT color screen can display measured values in four groups, with digital, bar graph, and curve displays (Figure 5). Additional features include:

- 100 ms scan rate for all channels

- Operation using the integrated navigator (jog/shuttle dial) or user-friendly operation with a PC using the integrated web server

- E-mail notifications can be sent in the event of alarms and limit violations

- Support for interfaces like Ethernet, RS232/485, USB, and optional slave function for Modbus RTU/TCP speeds integration into industrial automation systems

- The WebDAV app enables data saved on the SD card to be transmitted directly to a PC via HTTP without additional software.

Figure 5: This data manager can display values for four parameters and send the data to an external computer using its integrated web server. (Image source: DigiKey)

Figure 5: This data manager can display values for four parameters and send the data to an external computer using its integrated web server. (Image source: DigiKey)

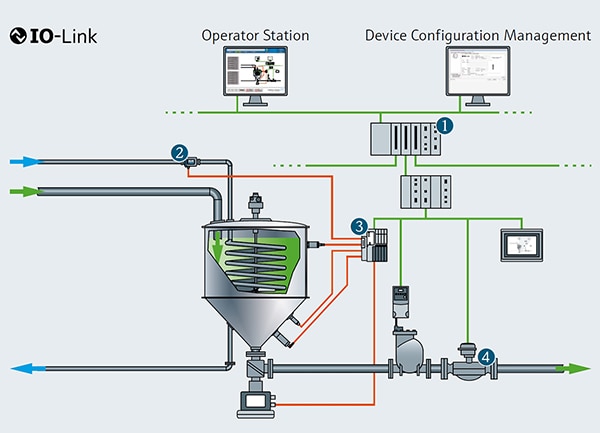

IO-Link and skids

IO-Link is standardized in International Electrotechnical Commission (IEC) 61131-9, where it’s called "Single-drop digital communication interface for small sensors and actuators (SDCI)."

Skids (modular processing systems within a frame, making them easier to transport and install) are often used in food and beverage processing, general machine building, and life sciences applications.

A typical skid will include less than 50 field devices like flow sensors, on/off switches, valves, pressure transducers, variable frequency drives, pumps, etc. Skids often rely on IO-Link connectivity. Skids sometimes include a human-machine interface like a flat panel display for local interactions and connect to the higher-level plant automation system using an industrial Ethernet protocol like EtherNet/IP or PROFINET. A typical skid architecture includes (Figure 6):

- An external control system ➊ that uses a protocol like EtherNet/IP or PROFINET (green lines) to connect each skid's dedicated controllers to coordinate their operations.

- In auxiliary operations like heat exchangers, devices like Picomag mag flow sensors ➋ use IO-Link (red lines) to provide additional process data and increase efficiency and up-time.

- An IO-Link master connection ➌ collects the information from individual sensors and actuators and transmits it to the skid controller using a protocol like EtherNet/IP or PROFINET. The IO-Link master can also communicate commands from the skid controller to devices like valves and actuators.

- Four wire devices that can’t connect using a three-wire IO-Link connector ➍ connect directly to the skid controller using a field-level protocol like EtherNet/IP or PROFINET.

Figure 6: IO-Link (red lines) is used for internal communication on a skid, and EtherNet/IP or PROFINET (green lines) is used for both internal communication and external connectivity. (Image source: Endress+Hauser)

Figure 6: IO-Link (red lines) is used for internal communication on a skid, and EtherNet/IP or PROFINET (green lines) is used for both internal communication and external connectivity. (Image source: Endress+Hauser)

Conclusion

Monitoring and measuring the quantity and movement of water is important in various applications. Fortunately, water management system designers have several tools at their disposal, including mag flow meters, ultrasonic- and radar-based level sensors, hydrostatic level sensors, and data managers. Those devices, along with IO-Link connectivity, are often used to build modular skids for applications like food and beverage processing.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.