Understanding Thermal Challenges in EV Charging Applications

2024-03-13

While the concept of electric vehicles (EVs) has been around for as long as gasoline vehicles, it's only in recent years that they've gained widespread acceptance. This surge in popularity can be attributed to significant advancements in EV technology coupled with substantial governmental backing. For instance, the European Union's decision to ban internal combustion vehicles by 2035 and mandate fast EV charging stations every 60 kilometers by 2025 serves as a clear testament to this anticipated surge in demand.

As EVs emerge as the dominant mode of transportation, factors such as battery range and even quicker charging rates will play pivotal roles in sustaining the global economy. Enhancements in EV charging infrastructure will necessitate advancements across various domains, with thermal management standing out as a key area requiring technological evolution.

AC and DC EV chargers – what’s the difference?

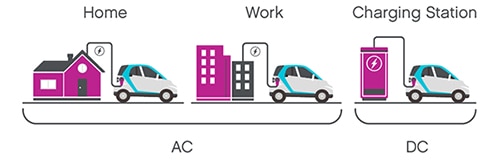

As the demand for quicker charging solutions intensifies, there have been both incremental and transformative shifts in approach. One notable change is the increasing adoption of DC chargers — a term that may initially seem ambiguous given that all battery systems inherently operate on DC electricity. However, the crucial distinction lies in where the conversion from AC to DC occurs within these systems.

The conventional AC charger, typically encountered in residential settings, primarily serves as a sophisticated interface responsible for communication, filtering, and regulating the flow of AC power to the vehicle. Subsequently, an onboard DC charger within the vehicle rectifies this power and charges the batteries. In contrast, a DC charger undertakes rectification prior to delivering power to the vehicle, transmitting it as a high-voltage DC source.

The primary advantage of DC chargers lies in their ability to eliminate many constraints related to weight and size by relocating the power conditioning components from the EV to an external structure.

Figure 1: DC chargers exhibit notably accelerated charging rates, albeit with heightened complexity and increased heat generation. (Image source: Same Sky)

Figure 1: DC chargers exhibit notably accelerated charging rates, albeit with heightened complexity and increased heat generation. (Image source: Same Sky)

By shedding weight and size constraints, DC chargers can seamlessly incorporate additional components to enhance both their current throughput and operating voltage. These chargers leverage state-of-the-art semiconductor devices for rectifying power, alongside filters and power resistors, all of which generate substantial heat during operation. While the contributions of filters and resistors to heat dissipation are noteworthy, the predominant heat emitter in an EV charging system is the Insulated Gate Bipolar Transistor (IGBT), a semiconductor device that has witnessed increased adoption in recent decades. This robust component has unlocked numerous possibilities in the charging domain, yet ensuring its adequate cooling remains a significant concern.

Tackling heat challenges

An Insulated-Gate Bipolar Transistor, or IGBT, essentially serves as a hybrid between a Field-Effect Transistor (FET) and a Bipolar Junction Transistor (BJT). Renowned for their capacity to endure high voltages, minimal on-resistance, rapid switching rates, and remarkable thermal resilience, IGBTs find optimal utility in high-power scenarios such as EV chargers.

In EV charging circuits, where IGBTs serve as rectifiers or inverters, their frequent switching operations lead to the generation of significant heat. Presently, the foremost thermal challenge pertains to the substantial escalation in heat dissipation associated with IGBTs. Over the past three decades, heat dissipation has soared more than tenfold, from 1.2 kW to 12.5 kW, with projections indicating further increases. Figure 2 below illustrates this trend in terms of power per unit surface area.

To put this into perspective, contemporary CPUs achieve power levels around 0.18 kW, corresponding to a modest 7 kW/cm2. The staggering disparity underscores the formidable thermal management hurdles facing IGBTs in high-power applications.

Figure 2: The power density of IGBTs has experienced significant advancements. (Image source: Same Sky)

Figure 2: The power density of IGBTs has experienced significant advancements. (Image source: Same Sky)

Two contributing factors play significant roles in enhancing the cooling of IGBTs. Firstly, the surface area of IGBTs is approximately twice that of CPUs. Secondly, IGBTs can withstand higher operating temperatures, reaching up to +170°C, whereas modern CPUs typically operate at only +105°C.

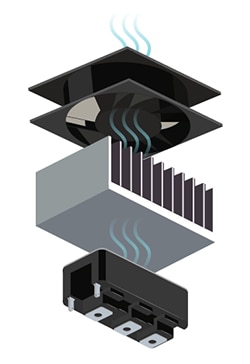

The most effective method for managing thermal conditions involves employing a combination of heatsinks and forced air. Semiconductor devices, such as IGBTs, generally exhibit extremely low thermal resistance internally, while the thermal resistance between the device and the surrounding air is comparatively high. Incorporating a heatsink substantially increases the available surface area for dissipating heat into the ambient air, thereby reducing thermal resistance. Additionally, directing airflow over the heatsink further enhances its efficacy. Given that the device-air interface represents the most significant thermal resistance in the system, minimizing it is crucial. The advantage of this straightforward approach lies in the reliability of passive heatsinks and the well-established technology of fans.

Same Sky has customized heatsinks specifically for EV charging applications, with dimensions of up to 950x350x75 mm. These heatsinks are capable of passively handling less demanding requirements or actively managing more demanding scenarios with forced air.

Figure 3: Utilizing heatsinks and fans represents a highly effective thermal management solution for IGBTs. (Image source: Same Sky)

Figure 3: Utilizing heatsinks and fans represents a highly effective thermal management solution for IGBTs. (Image source: Same Sky)

In addition to air cooling methods, liquid cooling offers an alternative for dissipating heat from high-power components like IGBTs. Water-cooling systems are attractive due to their ability to achieve the lowest thermal resistances. However, they come with higher costs and increased complexity compared to air cooling solutions. It's also worth noting that even in water-cooling setups, heatsinks and fans are still essential components for effective heat removal from the system.

Considering the associated costs and complexities, direct cooling of IGBTs using heatsinks and fans remains the preferred approach. Ongoing research efforts are focused on enhancing air cooling technologies specifically tailored for IGBT applications. This active research aims to optimize heat dissipation while minimizing costs and system complexities associated with liquid cooling methods.

Thermal system design considerations

The effectiveness of any cooling system heavily relies on the strategic placement of components to optimize airflow and enhance heat distribution. Insufficient spacing between components can impede airflow and limit the size of heatsinks that can be utilized. Therefore, it's crucial to strategically position critical heat-generating components throughout the entire system to facilitate efficient cooling.

In addition to component placement, the positioning of thermal sensors is equally vital. In large-scale systems like DC EV chargers, real-time temperature monitoring facilitated by control systems plays a crucial role in active thermal management. Automatic adjustments in cooling mechanisms based on temperature readings can optimize system performance and prevent overheating by regulating current output or adjusting fan speeds. However, the accuracy of these automatic adjustments is contingent upon the quality and precision of the temperature sensors. Poor placement of sensors can lead to inaccurate temperature readings, resulting in ineffective system responses. Therefore, careful consideration must be given to the placement of thermal sensors to ensure the accuracy and reliability of temperature monitoring and control.

Environmental factors

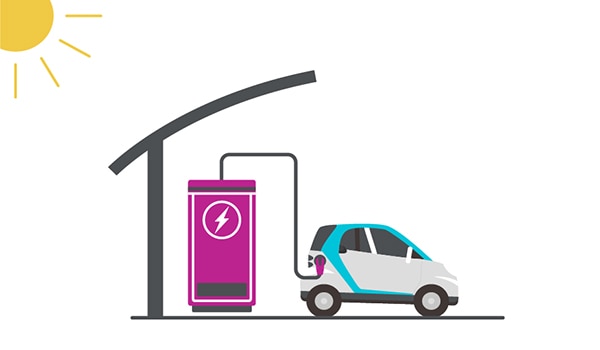

EV charging stations are frequently deployed in outdoor environments, subject to diverse weather conditions. Therefore, designing weather-resistant enclosures with proper ventilation and protection against elements, such as rain and extreme temperatures, is imperative to uphold optimal thermal performance. It's crucial to ensure that airflow paths and venting systems are engineered to prevent water ingress while maintaining unobstructed airflow.

Among external factors, solar heating from direct sunlight poses a significant challenge, leading to a considerable increase in the internal ambient temperature of the charger enclosure. While this presents a legitimate concern, the most efficient solution is relatively straightforward. Implementing well-designed shading structures with sufficient airflow between the shading and the charging unit effectively mitigates solar heating, thereby maintaining lower ambient temperatures within the charger enclosure.

Figure 4: Shielding chargers from direct sunlight presents a cost-efficient and efficient strategy for managing thermal conditions. (Image source: Same Sky)

Figure 4: Shielding chargers from direct sunlight presents a cost-efficient and efficient strategy for managing thermal conditions. (Image source: Same Sky)

What’s next?

In recent years, there has been a remarkable surge in the worldwide adoption of electric vehicles, with demand showing consistent and significant growth across various technological fronts. As the number of EVs on the road continues to escalate, the proliferation of charging infrastructure is expected to expand in lockstep. The effective operation and efficiency of chargers are paramount to the development of this burgeoning charging infrastructure. Cost-efficiency is also a critical factor, as the speed at which individuals and businesses integrate these chargers into their homes and establishments is contingent upon affordability.

Anticipating the continuous growth of EVs and chargers, one must acknowledge the evolving nature of the underlying technologies. This entails considering potential advancements in charging power and capacity, evolving software and hardware standards, and allowing room for unforeseen innovations. This proactive approach ensures that thermal management systems can adapt to evolving demands over time.

At their core, electric vehicle chargers share similar thermal management concerns with other dense, high-power electronic devices. However, the power density of the Insulated-Gate Bipolar Transistors (IGBTs) utilized in EV chargers, coupled with the escalating demands placed on them, presents a unique challenge. As charging speeds and battery capacities continue to rise, the imperative to develop chargers effectively and safely becomes increasingly stringent, demanding more from thermal management designers and engineers than ever before.

Same Sky offers a comprehensive range of thermal management components, coupled with industry-leading thermal design services, to support the evolving needs of the electric vehicle charging ecosystem.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.