An Introduction to Thermal Management

2021-12-14

Electronics systems are getting denser and hotter, which means many systems will require some method of managing said heat. While developing a thermal management solution is not necessary for every design, a fundamental understanding of how heat is generated, moved, and removed is essential to avoid having key components being damaged by elevated temperatures. In the end, thermal management needs to be considered in the early design stages rather than as a band-aid solution in the final design.

Thermal management basics

As more is demanded of electronic systems, theory states that there are three ways heat is transferred and thus components can be cooled: conduction, convection, and radiation.

Perhaps the most effective energy transfer method, conduction transfers thermal energy through physical contact between two objects where the cooler object naturally draws energy away from the hotter object. In general, this method requires the smallest surface area to move the greatest energy.

Figure 1: Conduction in practice. (Image source: Same Sky)

Figure 1: Conduction in practice. (Image source: Same Sky)

Second, convection redistributes thermal energy via the movement of air. As cooler air passes by a hotter object, it draws heat away from the object and carries it away as it continues to move through the device. This method can be accomplished by natural air convection or forced air convection via a fan.

Figure 2: Convection in practice. (Image source: Same Sky)

Figure 2: Convection in practice. (Image source: Same Sky)

Third, radiation is the emission of energy as an electromagnetic wave. Comparatively, this method is rather ineffective and ignored in most thermal calculations because it generally only applies to vacuum applications where conduction and convection are not options. In principle, radiation is the transfer of heat through the electromagnetic waves created when hot particles vibrate.

Figure 3: Radiation in practice. (Image source: Same Sky)

Figure 3: Radiation in practice. (Image source: Same Sky)

Although not one of the three basic thermal concepts outlined above, it is also important to mention thermal resistance, or impedance, which quantifies the effectiveness of thermal transmission between objects and is used extensively in designing thermal management solutions. Simply put, the lower the thermal impedance, the better the transfer of energy. Utilizing thermal impedance and a given ambient temperature, it is possible to calculate exactly how much power can be dissipated before reaching certain temperatures.

Thermal management components

There are three popular approaches to cooling electronic systems: heat sinks, fans, and Peltier modules. Each can be used alone but can reach even greater effectiveness when integrated together.

Heat sinks are available in many shapes and sizes. They are used to improve the effectiveness of convection cooling by decreasing the thermal impedance between the devices to which they are attached and the cooling medium, usually air. They do this by increasing the convection surface area and are made of a material that has a lower thermal impedance than typical semiconductors. Heat sinks are low cost and almost never fail or wear out but do tend to increase the volume of the electronic systems they are cooling. As passive components, heat sinks are often paired with fans to move the dissipated thermal energy away from the system more effectively. Fans or blowers create a steady flow of fresh cool air over a heat sink to maintain the temperature difference between it and the cooling air to ensure continuing efficient thermal energy transfer.

Fans and blowers are available in a wide variety of shapes and sizes with many different power options. The key specification is the airflow they can generate, typically measured in cubic feet per minute (CFM). Some fans and blowers have controls so that their speed can be adjusted to match current cooling needs, as part of a feedback-based control system. Fans help improve cooling, but designers need to be aware that they require power and sometimes control circuitry. In contrast to heat sinks, fans can also be noisy and have moving parts that make them more prone to failure.

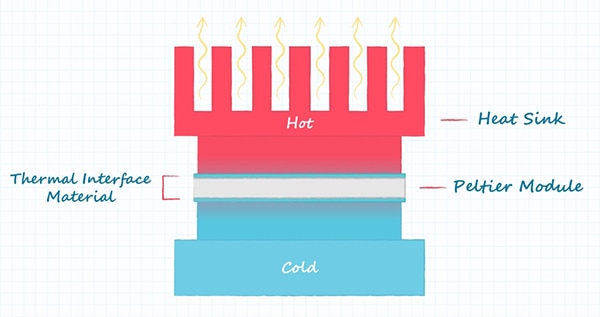

Peltier devices are semiconductor components that use the Peltier effect to transfer heat from one side of a module to another. Peltier devices must be provided with energy in order to move thermal energy, which actually adds heat to the system, so they are best used with heat sinks and fans. However, Peltier modules can achieve precise temperature regulation and can cool devices below the ambient temperature. Like heat sinks, they do not have moving parts, so they are flexible and robust in themselves, but again they may have to be used with fans, heat sinks, and control circuitry, increasing cost and complexity. For these reasons, Peltier modules are often reserved for the most demanding applications, such as extracting thermal energy from the heart of densely packed electronics systems.

Calculating thermal requirements

Whatever the final design requirements might be, there are well-established approaches to designing an effective cooling solution for electronic systems. To help illustrate how an engineer might approach creating an integrated thermal management solution, here is a hypothetical problem and solution:

This example will use a device in a 10 mm x 15 mm package that generates 3.3 W of heat at its steady state. The ambient temperature of the device’s operating environment is 50°C, with an ideal operational temperature of 40°C. No part of the system should exceed 80°C.

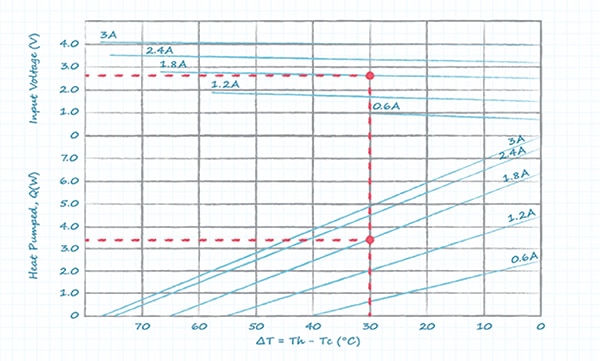

Figure 4: Peltier module performance graph from the CP30138H datasheet (Image source: Same Sky)

Figure 4: Peltier module performance graph from the CP30138H datasheet (Image source: Same Sky)

These specifications mean that a Peltier module is needed to bring the device’s temperature below the ambient. Same Sky offers the CP30138H, a Peltier module that can remove 3.3 W of thermal energy and reduce a device’s temperature to 10°C below ambient. The Peltier module is attached to the device using SF600G, a Thermal Interface Material (TIM) that reduces the thermal impedance between the device and the cooler. The CP30138H datasheet (Figure 4) shows that the Peltier module requires 1.8 A at 2.6 V, meaning that its operation will add 4.7 W of thermal energy to the system.

To remove the total 8 W of thermal energy from the Peltier module, a heat sink (the HSB28-606022) is attached to its other side, again using the SF600G TIM as an interface. The TIM has an area of 8.8 mm x 8.8 mm, and a thermal resistance of just under 1.08°C/W.

The heat sink has a thermal resistance of 0.9°C/W, assuming an airflow across it of 400 linear feet per minute (LFM).

This brings the total thermal resistance of the combined TIM and heat sink to 1.98°C/W.

To provide a consistent airflow of 400 LFM, a fan from the CFM-40BG series could be used.

The setup connects the device to be cooled to a Peltier module via a TIM. The upper surface of the Peltier module is connected to a heat sink via another TIM, and the whole assembly exists within 400 LFM of 50°C air.

Figure 5: Thermal management solution using a Peltier device, heat sink, two TIM layers, and fan (Image source: Same Sky)

Figure 5: Thermal management solution using a Peltier device, heat sink, two TIM layers, and fan (Image source: Same Sky)

Using this data, the steady-state temperature of the device can be calculated. The Peltier module will maintain its cool side at 36°C – at the cost of adding 4.7 W of heat to the assembly. The heat sink will have to dissipate 8 W of heat into a 50°C airflow environment, with a total thermal resistance between the Peltier module and ambient air of 1.98°C/W. Multiplying 8 W times 1.98°C/W determines the increase in temperature over ambient, which in this case is 15.84°C or 65.84°C total. This is well under the 80°C requirement, resulting in a thermal management solution that meets the needs of the system.

Conclusion

Thermal management is already necessary in consumer applications such as refrigeration, HVAC, 3D printing, and dehumidifiers. It is also used in scientific and industrial applications such as thermal cyclers for DNA synthesis and high-accuracy lasers. Heat sinks, fans, and Peltier modules can help to ensure that complex electronic systems remain within their thermal design limits. Same Sky offers a range of thermal management components to simplify this critical selection process.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.