Subtle Considerations for Connectors in Harsh and Extreme Environments

Contributed By DigiKey's North American Editors

2024-05-08

Connectors used in Industry 4.0 production, robotics, logistics equipment, heavy machinery, transportation systems, and operations like oil and gas production are often exposed to harsh and demanding environments like water and salt sprays, dust, humidity, significant levels of shock and vibration, temperature extremes, and the need to maintain electromagnetic compatibility (EMC). It takes a particular class of connectors to handle those extreme requirements and ensure high reliability.

Depending on the application, those connectors need to meet an array of standards from the International Electrotechnical Commission (IEC), United States Council for Automotive Research LLC (USCAR), Society of Automotive Engineers (SAE), the German AK Group, and others.

This article begins with a look at some subtle considerations, like the difference between weatherproof and waterproof, as well as the different levels of waterproof performance. It then examines the differences between the USCAR-2 and German LV 214 vibration testing. The article closes by presenting a series of connectors from Amphenol like wire-to-board, USB Type-C®, ix, M12 push-pull, filtered sub-D designs, and swappable battery solutions designed to meet the demands of harsh and extreme environments.

Weatherproof vs waterproof

Some connectors are touted as “weatherproof.” According to the U.S. National Weather Service, “weather is defined as the state of the atmosphere at a given time and place, with respect to variables such as temperature, moisture, wind speed and direction, and barometric pressure.” Weatherproof has different meanings in meteorology and connectors.

Weatherproof is not used in technical standards for connectors. Connector specifications don’t generally discuss various wind speed levels or barometric pressure. The meteorological definition of weather does not reference dust or other particles that may impact connector performance and is included in standards like IEC 60529, degrees of protection provided by enclosures (IP code), that apply to connectors.

IP rating system

In general, weatherproof connectors are designed for outdoor use and exposure to the weather. They are usually rated for IP65 and above and made using ultraviolet (UV) resistant materials to handle prolonged exposure to sunlight. Waterproof connectors have IP ratings of IP67 or higher. While it can be helpful to identify a connector as weatherproof or waterproof, it’s better to determine its specific IP rating.

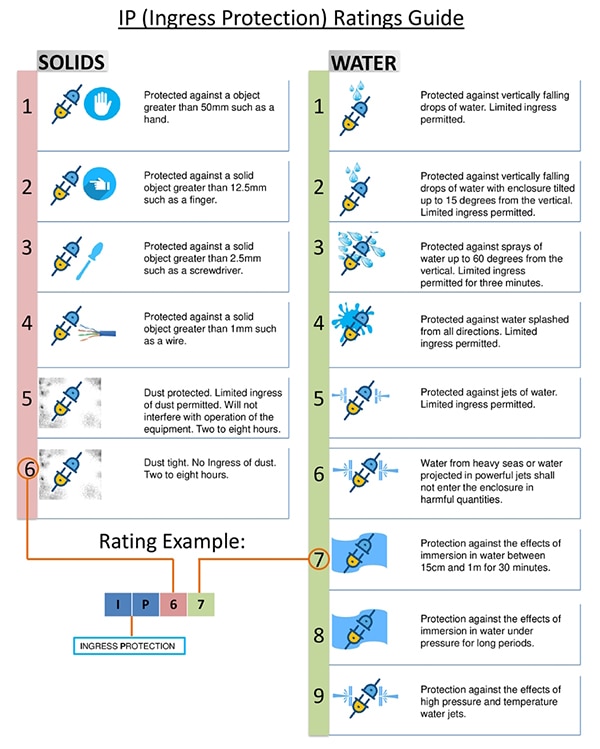

The lowest rating is IP11. That means protection from penetration by a 50 mm object like a hand, but water can penetrate. Connectors generally have much higher IP ratings. For example, weatherproof connectors rated for IP65 will not have their performance reduced by exposure to dust for two to eight hours, and they are protected from water jets with limited water ingress permitted.

Waterproof connectors with an IP67 rating are dust-tight and can be submerged to a depth of 1 meter for 30 minutes without water penetrating. For more demanding applications, there are even higher IP ratings for water protection (Figure 1).

Figure 1: Ingress protection rating definitions. (Image source: Amphenol)

Figure 1: Ingress protection rating definitions. (Image source: Amphenol)

Vibration variations

To ensure reliable operation, connectors need to have secure contacts. That can be challenging in high-vibration environments like industrial systems, heavy equipment, and transportation applications. Two commonly referenced vibration standards for connectors are LV214 and USCAR-2.

Both reference IEC 60068, SR (system requirements) series for environmental testing that covers a range of conditions, including sine, random and shock excitation, and extreme heat and cold. They reference IEC 60512-1-1, which specifies visual inspection during testing. While they have much in common, LV214 and USCAR-2 differ.

The AK Group of German automakers developed LV214. It’s focused on the quality of terminals using crimp force monitors. Terminals must meet specific criteria for crimp force characteristics. Crimp force monitors measure the applied pressure during the crimping process and ensure it meets the standard’s requirements.

USCAR-2 is more expansive. It includes testing at all stages of development as well as field analysis of terminals, connectors, and other components in high voltage (60 V to 600 V) automotive applications.

Both standards classify vibration into five intensity levels. In LV214, the levels range from S1, the most severe vibration, usually near the tires, to S5, the least severe, usually in the passenger cabin. Level S2 would be found in locations like the battery pack in an EV. The USCAR-2 ratings include V1 for chassis vibration profile and the more severe V2 engine vibration profile, and higher vibration testing levels include thermal cycling during the test. (Table 1).

|

Table 1: LV214 S2 and USCAR2 V1 requirements show differences in random vibration, duration, temperature cycling, and half-sine shock testing. (Table source: Amphenol)

Amphenol offers a wide range of industrial solutions. For example, the WireLock 1.8 mm wire-to-board connectors from Amphenol are USCAR-2 V2 and LV214 S2 compliant. They are designed for automotive, battery management systems, industrial and instrumentation applications, and robotics.

WireLock connectors have a nominal current rating of 3 A and handle wire sizes from 22 to 26 American wire gauge (AWG). Models with up to 40 positions in a double-row design and vertical and horizontal through-hole and surface mount configurations are available. There are four different colors for coding against mis-mating (Figure 2).

Figure 2: WireLock connectors have up to 40 positions and are USCAR2 V2 and LV214 S2 compliant. (Image source: Amphenol)

Figure 2: WireLock connectors have up to 40 positions and are USCAR2 V2 and LV214 S2 compliant. (Image source: Amphenol)

Waterproof and ruggedized USB Type-C

USB Type-C connectivity is vital across many applications, including industrial and harsh environments. It defines a connector style, not a protocol, and can support data transfer at up to 10 Gigabits per second (Gb/s) and power delivery. In addition to its application in USB connectivity, these connectors can be used for Thunderbolt, peripheral component interconnect express (PCIe), high-definition multimedia interface (HDMI), DisplayPort, and other protocols.

To support maximum data rates, all the grounded parts in these connectors, like the pins, latch, and EMC sheet, are grounded to reduce resonance. Controlling resonance limits the amount of crosstalk and electromagnetic interference (EMI) and contributes to improved connector performance.

Amphenol offers USB Type-C connectors in waterproof and ruggedized versions. The waterproof USB Type-C connectors are rated for IP68 and protected from water immersion for extended periods. Waterproofing is achieved using the company’s liquid injection molding (LIM) process to make a waterproof rubber O-ring on the outside of the connector which ensures that the stainless-steel shell is completely sealed. These 24-pin connectors are rated for 10,000 mating cycles.

For some applications, waterproofing is not enough. Designers can turn to the MUSBR Rugged Type-C USB connector for those applications. Like the waterproof versions, these ruggedized connectors are rated for 10,000 mating cycles.

They have a housing of UL94V-0-rated black engineering thermoplastic housed in a die-cast zinc alloy shell with nickel plating that provides stability to protect against shock, vibration, and impact. The rear cover is stainless steel, and a conductive silicone rubber gasket seal supports an IP67 rating and an operating temperature from -40°C to +105°C (Figure 3).

Figure 3: Amphenol offers USB Type-C connectors in waterproof (left) and ruggedized (right) versions. (Image source: Amphenol)

Figure 3: Amphenol offers USB Type-C connectors in waterproof (left) and ruggedized (right) versions. (Image source: Amphenol)

Weatherproof Ethernet

Industrial Ethernet enables several protocols that support real-time control and determinism in Industry 4.0 facilities, including EtherCAT, EtherNet/IP, PROFINET, Modbus TCP, and others. Amphenol provides a variety of industrial Ethernet solutions to suit specific application needs. They are available with IP ratings from IP20 to IP67.

The NDH Series sealed ix industrial latching interface is a rectangular push-pull connector and cable solution that’s weatherproof with an IP rating of IP67 and is in UV-resistant housing for use indoors, outdoors, and in harsh environments. They support Cat6A Ethernet connectivity using a standard IEC 61076-3-124 mating interface. Features include (Figure 4):

- Push-pull positive locking latch mechanism

- Small, lightweight, form factor

- Available as field-terminable plug kits or pre-made cable assemblies

- Mates with standard IP20 ix Industrial receptacles

Figure 4: This weatherproof industrial Ethernet connector (black assembly) is IP67-rated and is in a UV-resistant housing. (Image source: Amphenol)

Figure 4: This weatherproof industrial Ethernet connector (black assembly) is IP67-rated and is in a UV-resistant housing. (Image source: Amphenol)

M12 for harsh environments

Amphenol offers a range of product solutions for harsh environments, including the MPronto-12 M12 push-pull connectors. The MPronto-12 plug mates with all M12*1.0 sockets and complies with IEC 61076-2-101 from any manufacturer. They provide a quick and straightforward way to upgrade system performance in applications like industrial automation, heavy equipment, electric vehicles, and material handling equipment since they meet IP67, IP68, and IP69K ingress protection ratings and support M12 A, B, D, K, L, S, T, and X codes. Additional features include:

- -20°C to +105°C operating temperature

- Saves over 80% of installation time

- Audible click ensures positive mating

- Smaller than competitive M12 push-pull connectors that require a mating pair

Filtered D-sub

FCE17 D-sub filter connectors protect the integrity of data signals by filtering interference from conducted and radiated EMI. They are designed for the automotive, industrial, medical, data communications, and energy industries.

The filtering provided exceeds the performance of the same filter components mounted on the system printed circuit board (PCB), and including the filter components in the connector reduces solution size and cost. These filtered connectors fit the standard nonfiltered connector footprint and support simple EMI performance upgrades.

Various low-impedance chip capacitors (NP0 or X7R dielectrics) in standard values 50 picoFarads (pf) to 47000 pf are available to satisfy a wide range of filtering needs. Custom capacitance values are also available.

Amphenol’s stress-isolated technology produces connectors with superior mechanical and thermal shock capabilities. Mechanical stress on the connector or the contacts will not result in the cracking of the filter elements or the breaking of the electrical connection. In addition, radiated and conducted emissions from external EMI and from the device are shunted to ground, enhancing EMC performance.

Drone and robot swappable batteries

Designers of swappable battery systems for drones, robots, and e-mobility systems in warehouses and factories can use DURASWAP swappable battery connector solutions. They are available in two power and six signal configurations; custom designs are also offered. They can carry continuous currents from 15 to 70 amperes (A) and are rated for 10,000 mating cycles.

Blind mating is supported with a float of ±2 millimeters (mm). The first-mate last-break (FMLB) technology allows the ground connection to be established before the power connections and the ground connection to be maintained until after the power connections are broken. The metal bushing for panel fastening can withstand high torque loads for efficient panel IP sealing. Other features include (Figure 5):

- Guide pins to ensure proper mating

- IP67 rating when mated and unmated

- UL94V-0-rated housing materials

- Operating temperature range of -20°C to +90°C

Figure 5: These power connectors include FMLB technology and support blind mating with a ±2 mm float. (Image source: Amphenol)

Figure 5: These power connectors include FMLB technology and support blind mating with a ±2 mm float. (Image source: Amphenol)

Conclusion

This article has reviewed some considerations when specifying connectors for use in harsh and extreme environments. In some cases, it’s necessary to distinguish between USCAR-2 and LV214 vibration testing. As more and more systems are being used outdoors, it’s important to recognize the difference between weatherproof and waterproof and the various levels of waterproof performance. Finally, application-specific considerations can include using FMLB technology in power connectors and integrated EMI filtering in high-speed data connectors.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.