Simplifying Time-of-Flight Distance Measurements

Contributed By DigiKey's North American Editors

2017-01-05

Time-of-Flight (ToF) subsystems provide rapid measurement of distance for diverse applications, including automotive driver assistance systems, drones, and even user interfaces. Though widespread, ToF methods are technically demanding and require the designer to balance requirements such as accuracy, range, response time, and resolution with cost, power consumption and available footprint.

Dedicated ToF devices provide the flexibility to balance these requirements to meet the needs of specific applications. Two such dedicated devices, the Texas Instruments TDC7201 time-to-digital converter and the Intersil ISL29501 ToF signal-processing IC, present alternative approaches.

This article will give a brief overview of how ToF works before introducing these two solutions, how they address the needs of designers of ToF systems, and how to go about evaluating and using them.

How ToF works

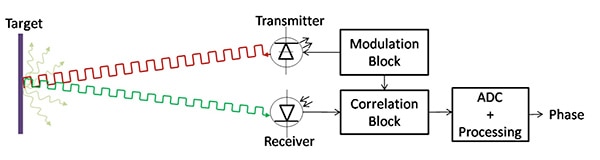

ToF methods lie at the heart of remote object sensing using light waves, ultrasound, and radar technologies. The principle of operation for these ToF systems is relatively simple. A transmitter emits a modulated signal and the target reflects a portion of the signal back to a receiver. The received signal is correlated with the transmitted signal by a dedicated processor which measures the flight time, and calculates the corresponding range to the target (Figure 1).

Figure 1: To measure distance to a target, ToF subsystems correlate transmitted and reflected signals for conversion to distance measurements by a dedicated processor. (Image source: Texas Instruments)

Key requirements

Among measurement technologies, light detection and ranging (LiDAR) has emerged as a popular choice for a growing array of consumer applications due to the availability of LED or laser transmitters, and their corresponding photodetectors. In working at light speed (about 300,000 km/s in air), however, LiDAR systems need to perform their function quickly and reliably, particularly for applications expected to detect close proximity targets. For example, flight time for a target 1 cm away is only about 67 picoseconds.

Custom-built ToF systems are able to achieve the kind of picosecond resolution needed for very short range measurements used in highly specialized applications. For these custom systems, engineers build ToF designs based on complex signal chains feeding measurement logic, typically implemented with an FPGA, to deliver the required performance levels.

For mainstream consumer applications, however, developers typically face less stringent performance challenges, with the emphasis shifting to low cost, size, and power consumption over pure measurement speed and resolution.

Even within the size and cost envelope expected for mainstream applications, ToF systems contend with a very broad range of signal requirements. Long-range or short-range applications must deal with interfering energy sources or reduced energy returns caused by distance and beam dispersion from airborne dust particles and/or moisture. In these cases, engineers may need to design specialized receiver signal chains to handle low signal-to-noise ratios, modulation, and correlation.

The challenges become even more pronounced with scanning ToF, where the transmitted energy paints a large swath of the target to build a more comprehensive depth perspective across the target scene.

For the more common single-point ranging systems to be discussed here, the emergence of specialized ToF detectors has significantly simplified the design of these systems. For general range-finding applications, the Texas Instruments TDC7201 time-to-digital converter (TDC) offers a general solution able to support technologies including ultrasonic, light, and radar. The 4 mm x 4 mm package integrates the precise timing circuits required to determine time of flight, allowing engineers to focus their efforts on optimizing the transmitter and receiver stages in their ToF design.

At the system level, the TDC7201 adds a simple requirement to the transmitter and receiver stages beyond those needed to generate and detect the signal. Engineers need to ensure that the transmitter and receiver each issue a 10 ns (min) pulse to the TDC7201 to indicate when a flight begins and ends. In turn, the TDC7201 automatically measures the time elapsed between the start and stop pulse signals and calculates the actual time of flight. Final results, raw data, and configuration data are all held in dedicated registers accessible through the device's SPI interface. With the addition of a host processor such as the TI MSP430, this modular design provides a sophisticated ToF system (Figure 2).

Figure 2: By integrating a pair of time-to-digital converters, the Texas Instruments TDC7201 significantly simplifies time-of-flight design for applications that require specialized transmitter and receiver stages. (Image source: Texas Instruments)

Besides reducing design footprint and parts count, these integrated devices typically feature low-power operating modes that help conserve power in battery-operated applications such as mobile devices and drones. For example, the Texas Instruments TDC7201 TDC consumes only about 2.7 mA in active mode, 100 µA in idle mode, and 600 nA in shutdown mode. In reality, a typical application might require only one or two range measurement operations per second, so idle states typically dominate overall power consumption.

Further, as described below, the TDC7201 provides measurement modes that reduce power consumption beyond the extended measurement periods required for long-range object detection.

Range flexibility

The TDC7201 integrates a pair of independent TDCs, comprising a high-frequency ring oscillator and counter. Each TDC includes a start and stop input, corresponding respectively, to the moment a light beam (or sound wave) is generated by the transmitter, and when it is detected by the receiver. For flight durations lasting less than about 2 µs, each TDC runs in its active state, using its internal ring oscillator to measure the flight time. Consequently in this mode, called measurement mode one, the device alternates between 100 µA power consumption in idle, and 2.7 mA in active mode.

The TDC7201 provides a second measurement mode that achieves reduced power consumption for flights of longer duration. In this mode, the device remains in an active state for no more than one cycle of an external 16 MHz (max) clock. While in an active state, the device uses its internal ring oscillator to measure the increment of time between a start or stop signal and the next rising edge of the external clock. Between these start and stop events, the device enters a low-power state that consumes only 140 µA. In this state, the TDC7201 turns off the TDC and uses an internal counter to count cycles of the external clock. When the flight ends, the TDC7201 adjusts this cycle count using the data from the two (start and stop) ring-oscillator measurements, storing the final result in a register.

With this approach, the device can measure long-duration flights while maintaining low power requirements because it spends most of the flight time operating in its 140 µA state, only very briefly switching to its 2.7 mA active state for the start and stop measurements.

Measurement mode two can achieve low-power operation for long-duration flights up to 8 ms. On the other hand, its reliance on counting full clock cycles means that the lower limit of its resolution is determined by the width of a cycle of the external clock. Consequently, for a nominal 8 MHz external clock, the minimum duration flight is 250 ns, or about 40 meters minimum range. To measure shorter distances, developers can use measurement mode one, which supports flights down to 12 ns (1.9 meters).

For applications that require very short-range proximity detection, the ToF system needs the ability to measure centimeters rather than meters. With its two TDCs, the TDC7201 provides a mechanism for developers to measure flights as fast as 0.25 ns, corresponding to about 4 cm. In this approach, the host MCU simultaneously issues a start to both TDCs (START1 and START2 in Figure 2).

In turn, as illustrated in Figure 2, the transmitter issues a stop signal to one of the TDCs when it generates the outgoing beam, and the receiver issues a stop signal to the other TDC when it receives the corresponding incoming signal. Using this approach, the TDC7201 provides separate accurate measurements of the start and stop time of the flight. The difference between the two is the actual flight time (Figure 3).

Figure 3: Developers can measure a flight duration (T3) down to 250 ps (4 cm) using the TDC7201's two independent time-to-digital converters to measure the difference between the start time of a flight (T1) and the stop time of the flight (T2). (Image source: Texas Instruments)

Integrated devices such as the TDC7201 are capable of supporting applications that require detection of targets approaching within centimeters. In practice, however, measurement consistency is typically more important than minimum achievable range for most applications. To help reduce the impact of transient measurement errors, the TDC7201 provides an averaging capability. Here, the device's internal TDCs perform several measurement cycles and compute the average result. As with its other operations, the TDC7201 performs this averaging sequence without intervention of the host MCU.

The TDC7201 also includes an automatic self-calibration capability designed to reduce errors due to temperature changes or drift. Performed automatically after each measurement, the self-calibration sequence compares the duration of one cycle of its internal ring oscillator to the external clock and stores the results in its internal registers. The device uses these self-calibration values when it converts its cycle counts to actual ToF values.

Although the device works to account for measurement errors, consistent results depend critically on the nature of the external clock. Significant clock jitter or frequency errors translate directly to errors in measurement. Consequently, measurement consistency requires selection of an oscillator with frequency errors and jitter characteristics that fall below the target measurement windows.

For example, the Texas Instruments TDC7201-ZAX-EVM evaluation module uses an Abracon LLC ASFLMB 8-MHz oscillator specified with a 50 ppm frequency stability and 10 ps jitter. For measurements over the durations supported by the TDC7201, these characteristics introduce errors that typically lie well below the resolution thresholds of most applications.

Integrated ToF solution

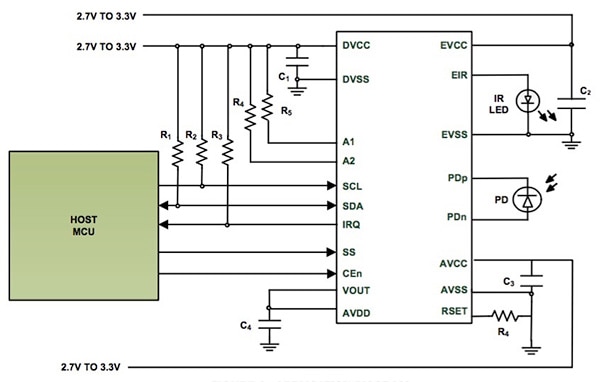

With the TDC7201, designers can build specialized transmitter driver and receiver signal chains to overcome adverse signaling conditions due to distance or environmental conditions. For many mainstream applications, however, parts count and design footprint are most critical. For these designs, the Intersil ISL29501 ToF signal processor which integrates transmitter and receiver stages, provides an effective solution for short-range object detection with minimal additional effort.

The ISL29501 integrates a digital-to-analog converter (DAC) that can source a 255 mA pulsed current to directly drive an external LED or laser. For the receiver, developers can connect a photodiode directly to dedicated input pins. This differential input connects to a complete analog signal chain comprised of a transimpedance amplifier (TIA), a low-noise amplifier (LNA), a demodulator, a bandpass filter, and an analog-to-digital converter (ADC). Beyond an LED and photodiode detector, the ISL29501 requires few additional external components to create a complete ToF solution able to detect targets up to two meters away (Figure 4).

Figure 4: The Intersil ISL29501 integrates a transmitter driver, a receiver signal chain and measurement logic, enabling developers to create a complete ToF design with only a few additional components. (Image source: Intersil)

The ISL29501 provides distance information as well as raw data to the host MCU, issuing interrupts as information becomes available. Performing a distance measurement with the device requires only a few transmissions across its I2C serial interface (Listing 1).

| Steps | Operation | Reg | Data | Comment |

|---|---|---|---|---|

| 1 | Write | 0x13 | 0x71 | Setup single shot mode |

| 2 | Write | 0x60 | 0x01 | Setup ISL29501 to interrupt when data ready |

| 3 | Read | 0x69 | Unused | Read clears interrupts |

| 4 | SS = '0' | - | - | Initiates a distance measurement |

| 5 | Wait for IRQ | - | - | Micro waits for external interrupt (data is ready) |

| 6 | Read | 0xD1 | Read Distance MSB | |

| 7 | Read | 0xD2 | Read Distance LSB | |

| 8 | Calculate | From 6 and 7 | Distance = (MSB * 256 + LSB)/2 |

Listing 1: Developers need to send only a few commands across the Intersil ISL29501's I2C bus to initiate independent operations such as a self-calibration or time measurement. (Code source: Intersil)

Conclusion

The ability to detect the distance to an object has emerged as an increasingly important feature for a growing number of applications. For many of these applications, reduced design footprint, cost, and power consumption outweigh the need to achieve very fine resolution and/or short-range distance measurement. For these applications, engineers can find integrated ToF devices able to meet specific combinations of requirements.

While the Texas Instruments TDC7201 TDC simplifies ToF designs based on specialized transmitter and receiver stages, the Intersil ISL29501 ToF signal processor provides a drop-in solution for proximity detection systems. Using these types of devices, engineers can respond quickly to the demand for cost-effective distance measurement capabilities in consumer and industrial products.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.