Sensing on a Zero Power Budget

Contributed By DigiKey's European Editors

2017-08-10

Simplifying IoT sensors

At any given time, much of the Internet of Things (IoT) could be doing nothing. IoT sensors are often required only to take measurements at infrequent intervals, send the resulting small quantity of data back to a collector, and then go back to consuming as little power as possible until the next measurement. Some smart sensors can be powered by a small battery, and operate for several years without recharging or replacement.

If the need for a permanently connected power source could be avoided altogether, sensors could be deployed for indefinite periods, and could be made much smaller and lighter. This creates the opportunity for new types of sensors such as non-invasive medical sensors that can be worn comfortably. A wireless temperature sensing patch attached to the skin, can be checked quickly from time to time, and allow the wearer much more freedom of movement than is possible with a wired sensor. Disposable patches also have hygienic benefits compared to reusable leaded sensors.

Many other applications could benefit from the advent of stick-on sensor patches, such as monitoring temperature, moisture or pressure. They could also be used for occupancy detection, connectionless monitoring of industrial processes, or smart agriculture such as monitoring soil or greenhouse conditions, or checking the body temperatures of livestock.

A new category of smart sensors is emerging that combine an ultra-low-power sensor with RFID technology. These sensors can be powered by the energy in the RF field emitted by the RFID reader only for the time required to take a reading. Batteryless sensors such as these collect data and forward it to the reader only on demand, and do not take measurements or store data independently.

Figure 1 presents a simplified overview of the functional blocks of a passive patch sensor, including the front-end interface to an analog or digital transducer, signal conditioning, data processing, wireless communication, and power management. Integrating these various elements to create a system capable of operating with the limited available RF field energy demands skilled low-power design, with careful attention to computational load and efficient power management. Such a sensor must also be small and flexible for easy positioning, and comfortable if it is to be a wearable device such as a bio sensor.

Figure 1: Functional elements of a passive sensor tag leveraging RFID technology.

Chip and sensor tag

Fortunately, several alternatives are available that are more highly integrated and optimized for passive sensing. Among these is the RF430FRL152H from Texas Instruments, which integrates all of the circuitry needed to implement the functions indicated in Figure 1, including a 14-bit sigma-delta ADC for connecting to analog sensors, and an SPI/I2C port that can be used to connect to digital sensors. The RF430FRL15xH has 2 KB of non-volatile storage, implemented with Ferroelectric RAM (FRAM) that delivers a combination of low power consumption, fast read and write speeds, infinite read/write endurance, and high electromagnetic immunity. In addition, because FRAM can operate from a low supply voltage, a charge pump to generate an elevated programming voltage is not needed. The integrated radio complies with ISO 15693, allowing the sensor to be read using a standard NFC/RFID reader, or NFC enabled smartphone.

An evaluation kit is available for the RF430FRL15xH, which comprises a baseboard with integrated antenna and sensors for ambient light and temperature. The supporting firmware includes the RF stack, driver libraries and boot code. The device is supported in TI’s Code Composer Studio design environment. A sensor hub booster pack expansion board is also available, which contains MEMS motion sensors, and sensors for pressure, humidity, temperature and light.

A reference design is available, which covers everything needed to build a bio sensor patch for measuring temperature or galvanic skin response, including an Android mobile app for interrogating the sensor using NFC, and a PC GUI for configuring and demonstrating the patch.

Integrated smart passive sensor

ON Semiconductor has taken a different approach by creating fully integrated smart passive sensors for moisture, temperature or pressure monitoring.

The ecosystem supporting these sensors includes an all-in-one development kit and a portable, battery-powered reader that has its own built-in GUI and IoT connection. This reader is ready to collect data from sensor tags. Several commercially available readers in fixed or handheld formats have also been tested with the tags.

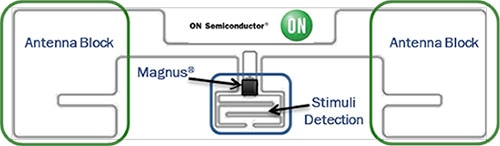

As Figure 2 shows, the ON Semiconductor smart passive sensor utilizes a stimulus loop that enables moisture or pressure to be monitored by measuring changes in impedance, along with a self-tuning, microcontroller-less IC that contains an adaptive RFID front end, an on-chip temperature sensor, and integrated memory for unique identification. The tag communicates using the Industry standard UHF Gen 2 protocol. When the reader initiates communication, the IC measures the condition of this loop and transmits the measured data with digitized temperature from the on-chip sensor to the reader. Integrated RSSI also allows detection of proximity or motion by monitoring RF signal strength.

Figure 2: ON Semiconductor’s fully integrated sensor tag measures pressure and moisture by detecting impedance changes in the built-in stimulus loop.

ON Semiconductor has created a family of sensors that are targeted for applications such as moisture level measurement, water intrusion detection and temperature measurement, as summarized in Table 1. They are suitable for various industrial and medical scenarios, such as quality control and environmental monitoring.

|

Table 1: A family of fully integrated sensors for moisture and temperature sensing.

Handheld readers compliant with NFC and RFID standards are readily available for reading smart passive sensors, and proven in use cases such as supply chain management. A passive sensor can be scanned to take a reading in much the same way as an RFID tag is scanned to record receipt or dispatch of goods. Upgrading RFID tags to sensor tags in a supply chain situation gives extra power to record the condition of goods anywhere in the supply chain. For example, to verify that specified storage conditions have been met, or help identify a point in the supply chain where damage might have occurred.

Scanning with a mobile handheld reader is by no means the only way to collect data from passive sensors. A fixed reader can be positioned at a suitable location to capture data from any sensor passing within range. This can support accurate monitoring of industrial equipment for maintenance purposes. Several sensors can be positioned in pre-determined locations, such as on a motor or bearing housing, or electronic power module, and scanned periodically. Without sensor tags, this type of analysis may require measurements to be taken manually using a device like an infrared thermometer. This can introduce inaccuracies if successive scans are made at slightly different locations on the surface being measured, or at slightly different time intervals. A fixed reader and permanently attached sensors can eliminate these errors, and the collected readings can be easily forwarded to a host computer or the Cloud for analysis.

Conclusion

The extreme power constraints prevailing in IoT applications are driving inventive solutions and the emergence of new classes of devices. Smart passive sensors that take advantage of existing RFID technology can be deployed for long periods with no battery or maintenance required, and energized only when a measurement is needed. In addition to their batteryless simplicity, they can also deliver advantages such as greater safety, repeatability, and user comfort in a wide variety of applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.