Selecting Enclosures to Protect Electronics Indoors and Outdoors

Contributed By DigiKey's North American Editors

2024-05-23

Although the inside of systems may change, electronic printed circuit boards (pc boards) must be externally protected from the environmental intrusions of heat, cold, light, water, dust, humidity, and chemicals. They also need mechanical isolation to protect them from tampering and prevent electrical shock and short circuits. In some cases, they may further require isolation from shock and vibration. Enclosures must also shield from electric and magnetic fields and electronic interference. Finally, electronic circuit boards need protection from catastrophic events like fires and flooding.

While designers can build their own enclosures, doing so is time-consuming and doesn’t provide optimal results. The solution is to buy enclosures off-the-shelf from a reputable supplier with a wide range of options with respect to materials, sizes, mounting, and sealing.

This article discusses the selection criteria for plastic enclosures suitable for indoor and outdoor use. It uses examples from Hammond Manufacturing and focuses on selecting designs with appropriate sealing and flame-retardant characteristics.

Choosing an electronics enclosure

Before selecting an enclosure, the device’s location and environment need to be specified. Will it be mounted indoors or outdoors? Will it be mounted on a wall, a pole, or a bench? Does it have to be waterproof, corrosion resistant, dustproof, sun tolerant, or flameproof? Will the mounted sub-assembly be a pc board or a DIN rail module? Selection can only begin once these questions are answered.

Small electronic enclosures are available in a variety of materials. Hammond Manufacturing designs and builds small electronic enclosures made of steel, stainless steel, sheet and die-cast aluminum, ABS plastic, and polycarbonate. They are available in an assortment of sizes and geometric configurations. In recent years, plastic enclosures have gained prominence primarily due to their lower cost and lighter weight while offering increased environmental protection.

Plastic enclosures

The Hammond Manufacturing 1555F series (Figure 1) is an example of a series of plastic watertight enclosures designed to operate in harsh environments. Constructed of either ABS plastic or polycarbonate materials, they are intended for wall mounting and include an integral mounting flange, mounting bosses, and a sealing gasket.

Figure 1: Shown are the key structural features of a Hammond Manufacturing 1555F series enclosure. (Image source: Hammond Manufacturing)

Figure 1: Shown are the key structural features of a Hammond Manufacturing 1555F series enclosure. (Image source: Hammond Manufacturing)

The 1555F series includes many of the common features of Hammond Manufacturing plastic enclosures, including a smooth molded surface that is recessed to accept a label or a membrane keypad. All include integral bosses to mount pc boards, and some also include mounts for DIN rail modules. These modules are sealed using a tongue-and-groove slot to accept a replaceable, high-temperature, UL-listed silicone gasket. Tongue-and-groove slots hold the gasket and provide a better seal than the simple lap-joint seal used on die-cast enclosures. All the hardware is corrosion resistant, including stainless steel or brass. The cover screws and gasket are included and are self-captivating to prevent loss.

Replacement hardware and gaskets are also available. The series enclosures are standard RAL-7035 light gray with an easy-to-clean satin finish, except for the keypad recess which is smooth. The molded-in mounting flange is a characteristic of the 1555F series. All products' accessories include galvanized steel mounting panels to secure heavy pc boards. The metallic panel also serves as a base for internal shields for electromagnetic interference (EMI) suppression. Access control options include breather vents, pressure compensation plugs, liquid-tight strain-relief cord grips, and rainproof ventilators. These allow wire access and pressure equalization without compromising the watertight integrity of the enclosure.

The ABS models are recommended for indoor use only. They have an ingress protection (IP) rating of IP66, indicating complete protection against dust and temporary water flooding. Polycarbonate enclosures are UV-stabilized and can be used indoors and outdoors. They are IP68 rated, indicating they are protected against dust and full water submersion. They are UL-rated (both cUL and UL508A listed) and have a flammability rating of UL94 5VA. They are designed to meet NEMA type 4, 4X, 6, 6P, 12, and 13 ratings.

The series includes 23 different sizes in each material from 2.56 inches (in.) (65 millimeters [mm]) long by 2.56 in. (65 mm) wide by 1.67 in. (42.4 mm) high to 9.45 in. (240 mm) long by 6.34 in. (161 mm) wide by 2.40 in. (61 mm) high.

The Hammond Manufacturing 1555H2F42GY (Figure 2) is an example of a 1555F series enclosure. It is a flanged polycarbonate box that measures 7.086 in. (180 mm) long by 4.723 in. (120 mm) wide by 2.441 in. (62 mm) high.

Figure 2: The Hammond Manufacturing 1555H2F42GY is an IP68-rated watertight polycarbonate enclosure. (Image source: Hammond Manufacturing)

Figure 2: The Hammond Manufacturing 1555H2F42GY is an IP68-rated watertight polycarbonate enclosure. (Image source: Hammond Manufacturing)

This is a mid-sized enclosure intended for wall mounting. It has four circular mounting holes on the flange for permanent mounting and two keyhole openings for fast mounting and removal. Four M4 stainless steel screws mate with stainless steel inserts to mount the box to the base. The cover screws and inserts are outside of the gasket perimeter to ensure proper gasket sealing.

The 1557 series (Figure 3) is watertight and allows designers to choose from various mounting options. It is available in ABS plastic and polycarbonate materials with both offered in black or gray finishes. The materials meet the same standards as the 1555F series. Configured with rounded corners, it offers designers a contemporary look while maintaining dust and watertight integrity.

Figure 3: The 1557 series is available in black or gray in both ABS and polycarbonate materials with multiple mounting options. (Image source: Hammond Manufacturing)

Figure 3: The 1557 series is available in black or gray in both ABS and polycarbonate materials with multiple mounting options. (Image source: Hammond Manufacturing)

These enclosures are available in eight different sizes with square cross sections from 3.15 in. (80 mm) by 3.15 in. (80 mm) to 7.874 in. (200 mm) by 7.874 in. (200 mm) with heights of 1.77 in. (45 mm), 2.36 in. (60 mm), or 2.76 in. (70 mm).

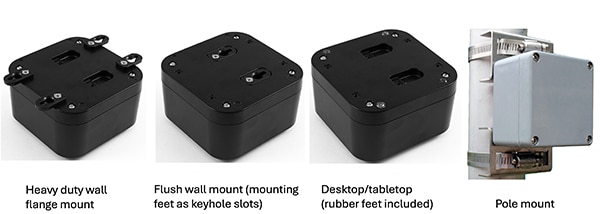

The 1557 series' mounting options include wall mount, tabletop mount, and an optional pole mount (Figure 4).

Figure 4: Mounting options for the 1557 series include two wall mounts, a desktop/tabletop mount, and a pole mount. (Image source: Hammond Manufacturing)

Figure 4: Mounting options for the 1557 series include two wall mounts, a desktop/tabletop mount, and a pole mount. (Image source: Hammond Manufacturing)

The 1557DBK from the 1557 series measures 4.724 in. (120 mm) by 4.724 in. (120 mm) by 1.772 in. (45 mm) and consists of black ABS plastic. The 1557DBK is intended for indoor use with an ingress protection rating of IP66. Available options for this series include pole mount, an aluminum inner mounting panel, liquid-tight cord grips, a breather kit, and pressure compensation plugs. Replacement gaskets, lid screws, mounting screws, and rubber feet are also available.

The 1554 and 1555 series are general-purpose ABS plastic or polycarbonate enclosures. They have the same standards conformance for each material as discussed with the previous enclosures. Each series offers 32 different sizes. Box sizes vary from 2.6 in. (66 mm) by 2.6 in. (66 mm) by 1.6 in. (40 mm) to 11.81 in. (300 mm) by 9.45 in. (240 mm) by 4.72 in. (120 mm). Cross sections are either square or rectangular.

The primary difference between the series is that the 1555 (Figure 5, left) uses a recessed cover for label or keypad mounting, while the 1554 (Figure 5, right) has a flat cover.

Figure 5: The 1555 series (left) features a recessed cover to accommodate labels or membrane keypads, while the 1554 series (right) has a flat cover. (Image source: Hammond Manufacturing)

Figure 5: The 1555 series (left) features a recessed cover to accommodate labels or membrane keypads, while the 1554 series (right) has a flat cover. (Image source: Hammond Manufacturing)

The polycarbonate versions of the 1554 series are available with opaque gray, clear, or translucent smoked covers. The ABS enclosure covers are only available in opaque gray. The clear and translucent covers are helpful to see internal indicators and readouts.

Options for the 1554 and 1555 series include inner panels of 16 gauge galvanized steel. Other options include a breather kit, pressure compensator plug, hole plugs, a small rainproof ventilator, liquid-tight cord grips, and a pole mount kit. Replaceable parts include spare gaskets and mounting and cover screws.

An example of the 1554 series is the 1554CGY. It is an ABS enclosure with dimensions of 4.724 in. (120 mm) by 2.559 in. (65 mm) by 1.575 in. (40 mm).

The 1555HGY is an example from the 1555 series. It is an ABS enclosure with dimensions of 7.087 in. (180 mm) by 4.724 in. (120 mm) by 2.362 in. (60 mm).

Conclusion

Hammond Manufacturing offers a wide variety of off-the-shelf enclosures in a range of materials and an even more comprehensive selection of sizes. These enclosures include mounting bosses for circuit boards or DIN modules, internal metallic panels, access ports, and flexible mounting options. This variety allows designers to choose from various sealing and mounting options to meet their needs.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.