10 Tips When Specifying an Electronic Enclosure

2024-05-30

There are many things to consider when beginning a new project, not least of which is the enclosure that will house the user’s components. The enclosure will be what consumers see and interact with, and the user wants to ensure that it has all the qualities needed for their application.

Based on Hammond Manufacturing’s experience as an enclosure manufacturer, there are 10 common—but vital—criteria to keep in mind when selecting an enclosure.

1. Size

In a perfect world, the enclosure will be selected before the PCB is designed. This ensures that the board will be exactly the right size and, if the enclosure has mounting posts, that the mounting holes are in just the right place. Sometimes it’s inevitable that the reverse is the case, and the user must match their board to a box.

How big is the PCB? Is it to be mounted horizontally or vertically? Many plastic enclosures have slots molded into the sides of the enclosure for direct vertical mounting or PCB mounting bosses molded into the top and base for horizontal mounting. Extruded aluminum enclosures will typically have full length slots in the sides for horizontal PCB mounting. How much space, if any, does there need to be on the external faces for indicators, switches, connectors, cable entries, and similar components? What height is required for board-mounted components or multiple horizontal boards?

Figure 1: Plastic enclosures molded with internal card guides from Hammond’s 1591T series. (Image source: Hammond Manufacturing)

Figure 1: Plastic enclosures molded with internal card guides from Hammond’s 1591T series. (Image source: Hammond Manufacturing)

Figure 2: An extruded aluminum enclosure with PC board slots from Hammond’s 1455 series. (Image source: Hammond Manufacturing)

Figure 2: An extruded aluminum enclosure with PC board slots from Hammond’s 1455 series. (Image source: Hammond Manufacturing)

2. Installed environment

Where will the product be used? Inside, outside, or both? For outside installation, UV stability is a potential issue for plastic enclosures, so polycarbonate is the default choice. For mobile applications such as road and rail, is shock and vibration likely to be a concern? Is there a risk of water or dust ingress (see point 5 below)? Are there likely to be contaminants present, such as oils or chemicals? Is resistance to impact damage a possible problem? Are particularly high or low temperatures expected?

ABS is great for indoor and handheld use. Polycarbonate, due to its good temperature resistance, UV stability, and ability to withstand impact, makes a good material for outdoor and more industrial uses. Metal, such as diecast aluminum, has superior impact and temperature resistance.

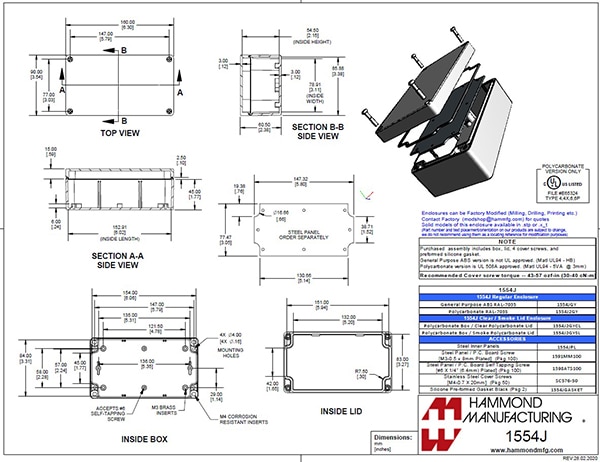

Figure 3: A polycarbonate enclosure with clear lid from Hammond’s 1554 series. (Image source: Hammond Manufacturing)

Figure 3: A polycarbonate enclosure with clear lid from Hammond’s 1554 series. (Image source: Hammond Manufacturing)

3. Material

For small enclosures, the choice is typically between plastic (including ABS and polycarbonate) and metal (including diecast, folded, or extruded aluminum and steel). Polycarbonate would normally be specified for outdoor use because it resists becoming brittle or discolored from the sun better than ABS.

Aluminum enclosures give good impact resistance and are intrinsically electrically conductive, although painted or anodized finishes must not cover mating areas to preserve continuity throughout the enclosure. Some designs of extruded enclosures offer features such as multiple fins to increase the surface area to improve heat dissipation. Diecast aluminum housings are strong and robust; they do not corrode, are electrically conductive, have an intrinsically high level of electro-magnetic attenuation, and are easily machined. For applications where protection against shock damage is important, where EMC is likely to be an issue, or where high temperatures, dust, or water are expected to be present, the diecast enclosure is the ideal low-cost choice.

4. EMC (Electromagnetic Compatibility)

Plastic enclosures have one specific weakness: they offer no EMC attenuation. If EMI or RFI emitted by the housed electronics or their susceptibility to external fields is a potential problem, the lack of screening could be an issue. Internal coatings in a variety of materials can be applied to the inner surfaces of a plastic enclosure to give different degrees of attenuation dependent on the project requirements. By offering different materials in a range of thicknesses, the most cost-effective and technically appropriate solution can be provided.

Metal enclosures, providing they are designed in such a way that electrical continuity is present between the top, base, and removable panels, will provide a level of EMC likely to be more than sufficient for the majority of commercial applications. A conductive gasket will be used to electrically link the two halves of the enclosure.

5. Environmental sealing

Will the enclosure be subject to environmental risks like water or dust? The relevant international standard is EN 60529, which defines ratings written as IPXX where the first digit defines the protection against solid objects and the second the protection against water ingress.

Typically, enclosures rated at IP54 are suitable for general purpose use. For installation in environments where dust and water are likely to be present, IP66, 67, or 68 would normally be specified and achieved with use of a gasket. The highest rating is IP69K, which gives protection against steam cleaning at high pressure. In North America, enclosures’ environmental sealing is normally defined as a NEMA (National Electrical Manufacturers Association) number. NEMA ratings also require additional product features and tests such as functionality under icing conditions, knockouts for cable connections, and others not addressed by IP ratings.

Figure 4: Some enclosures, such as this 1551SNAP series case, are designed to let in the elements, for applications like environmental sensing. (Image source: Hammond Manufacturing)

Figure 4: Some enclosures, such as this 1551SNAP series case, are designed to let in the elements, for applications like environmental sensing. (Image source: Hammond Manufacturing)

6. Hardware

Enclosure panels and covers must be secured to their mating half and there are two main methods for plastic and diecast enclosures. Either a self-tapping screw is secured directly into the material of the base, or a machine screw mates with a threaded insert (or bushing) located in the base. A machine screw is preferable if repeated openings and closures are anticipated during the life of the equipment, while a self-tapping screw is sufficient for “set it and forget it” type applications.

Figure 5: An economy plastic enclosure without brass inserts (left) and a flame retardant plastic enclosure with brass inserts (right) from Hammond’s 1591 series. (Image source: Hammond Manufacturing)

Figure 5: An economy plastic enclosure without brass inserts (left) and a flame retardant plastic enclosure with brass inserts (right) from Hammond’s 1591 series. (Image source: Hammond Manufacturing)

7. Appearance

Although aesthetics can certainly be subjective, the user probably has at least a general idea of how they want the product to look and feel. Plastic enclosures offer a choice of opaque and translucent material in a variety of colors and are lightweight, many with recessed lids for membrane keypads and displays. Extruded enclosures have a stylish anodize finish that can be paired with accessories like colorful plastic bezels for a look that pops. Diecast aluminum enclosures can be painted in a variety of different colors and are favored for highly customized products like guitar pedals. Sometimes a rugged, unfinished diecast enclosure is all the user needs!

Figure 6: Painted “stomp box” diecast aluminum enclosures from Hammond’s 1590 series. (Image source: Hammond Manufacturing)

Figure 6: Painted “stomp box” diecast aluminum enclosures from Hammond’s 1590 series. (Image source: Hammond Manufacturing)

8. Product and support availability

Standard enclosures for the electronics and electrical industries are produced in a huge variety of sizes, styles, and types by many specialist manufacturers. A molded, extruded, or diecast enclosure may appear to be just a simple box, but in fact it is the result of extensive design expertise that has resulted in a feature-rich housing, suitable for use in a wide variety of applications and environments. Distributors keep extensive stock of standard enclosures on the shelf, and the latest trend is that distributors are now joining manufacturers in providing technical support to their customers, working with them at the design stage to help choose the most appropriate enclosure for the application.

9. Downloadable drawings and support materials

Any reputable enclosure manufacturer and distributor will provide a comprehensive library of technical information on its website. Typical downloadable resources include dimensioned drawings in PDF and CAD formats to assist with design and modification requirements, technical details, and key product attributes.

Figure 7: Dimensioned drawings are available to download for all Hammond enclosures. (Image source: Hammond Manufacturing)

Figure 7: Dimensioned drawings are available to download for all Hammond enclosures. (Image source: Hammond Manufacturing)

10. Customization

All enclosures need to be modified in some way to be useful, such as by adding holes for connectors or printing labels and a logo. Hammond offers in-house machining and printing services with a small minimum order quantity. The type of enclosure will open up unique avenues for customization. For example, we can install pressed-in hardware like standoffs into metal enclosures, customize the length of extruded aluminum enclosures, and mold plastic enclosures in custom colors. For more information about modified enclosures, visit DigiKey’s Custom Enclosures page.

Figure 8: A 1455 series extruded aluminum enclosure customzied with colorful bezels, cutouts, and printing. (Image source: Hammond Manufacturing)

Figure 8: A 1455 series extruded aluminum enclosure customzied with colorful bezels, cutouts, and printing. (Image source: Hammond Manufacturing)

Conclusion

Not all these tips will apply to every project, but considering them will help designers keep the big picture in mind - from understanding the short-term and long-term availability of a particular enclosure, to sizing up the perfect box for the next project. Factoring in the dimensional and technical requirements, as well as feasibility and aesthetics, ensures every project runs as smoothly as possible from prototype to rollout.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.