Revolutionizing Building Automation with 10BASE-T1L

Contributed By DigiKey's European Editors

2023-10-24

The field of building automation has seen tremendous improvement in recent years, which has made it possible for commercial and residential buildings to be managed more effectively.

Today, there is a widespread need for efficient and sustainable systems to make buildings healthier environments for occupiers while minimizing power consumption and increasing real-time high-data throughput and control capabilities.

The challenges of building automation

Designers and system integrators face several challenges posed by building automation including:

- Rapid obsolescence of technology: Existing systems may be rendered obsolete because of rapid improvements in technology, resulting in reduced functionality, support, and integration with new technologies.

- Efficiency and sustainability requirements: Energy efficiency, fault detection/diagnostics improvements, indoor environmental quality (IEQ) monitoring, and water resource management are all necessities for building owners and operators.

- Data analytics and optimization: Modern tendencies in data analytics and optimization have necessitated the incorporation of data collection, analysis, and interpretation capabilities into building automation systems. This paves the way for data-driven optimization of building performance, inefficiency detection, and corrective action implementation.

- Interoperability: It is difficult to ensure compatibility and integration between systems offered by different vendors. Additionally, a system's efficiency can be hampered by incompatibilities, proprietary protocols, and a lack of standardization.

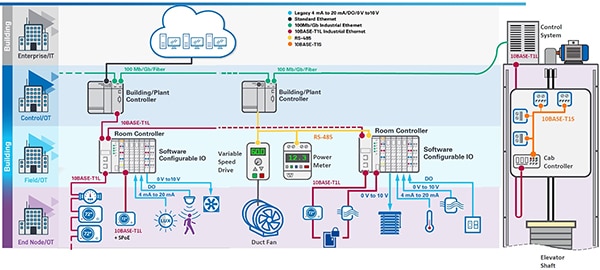

As shown in Figure 1, addressing these issues will require smart buildings capable of:

- Enabling centralized configuration and management at the enterprise level through cloud connection

- Removing the dependence from translation gateways at the controller level

- Moving the intelligence to the edge, enabling sensors and actuators to exchange a high volume of data

Figure 1: Providing buildings with interoperable edge-to-cloud connectivity. (Source: ADI)

Figure 1: Providing buildings with interoperable edge-to-cloud connectivity. (Source: ADI)

The significance of data communication is growing in the industrial and building automation domains. The current rise in data volumes has led to the realization that traditional solutions are approaching their physiological threshold. Consequently, Ethernet is emerging as the prevailing communication standard. The conventional 4-wire Ethernet solution has transformed into a 2-wire solution referred to as 10BASE-T1L, which comprises a single pair of twisted wires.

How the 10BASE-T1L standard drives the change

The 2019 introduction of the IEEE 802.3cg 10BASE-T1L specification has resolved several industrial and building management communication issues by enabling 10 Mbps full-duplex communications up to 1,000 meters over a single pair of twisted wires.

The 10BASE-T1L standard overcomes several limitations of traditional communication systems, including limitations related to cabling, bandwidth, distance, and power in the field of building automation. Here is a breakdown of how the 10BASE-T1L standard addresses these limitations:

- Cabling: The 10BASE-T1L standard enables seamless Ethernet connectivity for field-level devices such as sensors and actuators by providing a physical layer solution capable of transmitting Ethernet signals and power over a single twisted pair of cables. This eliminates the need for complex and costly cabling infrastructure, thereby facilitating the deployment and installation of Ethernet network-building automation. Aside from that, Ethernet packets can go directly from the edge to the cloud, removing the need for gateway translation.

- Bandwidth: The 10BASE-T1L standard supports data transfer rates of up to 10 Mbps, which is adequate for a variety of building automation applications. This bandwidth is higher than conventional field buses (where it is limited to a few kbps) and enables the transmission of values from sensors or directly to actuators, as well as additional device parameters, such as configuration and parameterization data.

- Distance: The 10BASE-T1L standard's ability to support long-distance Ethernet connections is one of its primary advantages. It permits connections up to 1 kilometer in length, which is considerably longer than the traditional Ethernet standard. This makes it suitable for applications where devices are dispersed over large areas, such as industrial plants and automobile assembly plants.

Furthermore, the 10BASE-T1L standard is intended for use in settings with limited power resources due to its low power requirements. This is of paramount importance in field-level devices, where battery life and power consumption are critical.

In some cases, it is necessary to provide via 10BASE-T1L both data and power (up to 60 W in non-intrinsically safe areas) as defined within the standard. 10BASE-T1L supports two amplitude modes: 2.4 V for cable lengths up to 1,000 m, and 1.0 V for shorter lengths up to 200 m. Through the 1.0 V peak-to-peak amplitude mode, this technology can also be used in explosion-protected environments (hazardous areas) and meets the strict maximum current consumption requirements that apply (maximum power is limited to 500 mW).

A reference use case

A typical use case of the 10BASE-T1L standard is shown in Figure 2. This smart building application exploits the properties of 10BASE-T1L to collect and aggregate data at different levels, from the end node (sensors and actuators) up to the enterprise/IT level on the cloud.

Room controllers can have direct (point-to-point) connections with the field devices or connect to a series of devices linked in a daisy chain. Moreover, each room controller can be configured to accept connections from legacy devices.

Each building has its plant controller, which is connected to a plethora of room controllers via 10BASE-T1L links as well as to other buildings’ plant controllers via 100 Mb/Gb industrial Ethernet.

For short-range connection to sensors and actuators (up to 25 meters), as in the case of the elevator’s cab controller on the right of Figure 2, the 10BASE-T1S standard is more appropriate.

Figure 2: A smart building use case. (Source: ADI)

Figure 2: A smart building use case. (Source: ADI)

10BASE-T1L transceiver

Analog Devices has developed the ADIN1110, which is an ultra-low power, single port, 10BASE-T1L transceiver suitable for Ethernet-based applications in industrial and building automation. It complies with the IEEE 802.3cg-2019 Ethernet standard for long reach, 10 Mbps single pair Ethernet (SPE), and was designed for use in those applications.

As shown in Figure 3, the component incorporates a media access control (MAC) interface. This makes it possible to establish direct contact with several host controllers using a serial peripheral interface (SPI) that uses four wires. This SPI allows for the use of processors with reduced power consumption because there is no need for an integrated MAC, resulting in the lowest overall power consumption for the system. Both the Open Alliance SPI protocol and a generic SPI protocol are available as options for use with the SPI when configuring it.

The ADIN1110 incorporates voltage supply monitoring and power-on reset (POR) circuitry to enhance system-level robustness. It also has a low power consumption (typically 42 mW) and supports 1 VPP and 2.4 VPP transmit levels, as well as auto-negotiation and 16 MAC addresses for frame filtering.

Figure 3: Block diagram of the ADIN1110 MAC PHY transceiver. (Source: ADI)

Figure 3: Block diagram of the ADIN1110 MAC PHY transceiver. (Source: ADI)

10BASE-T1L's greater range makes it possible to install automation devices in larger buildings while maintaining seamless connectivity. Thanks to this flexibility and scalability, facility managers can effortlessly monitor and modify settings for applications like lighting, climate/HVAC control, security, and energy management.

Additionally, 10BASE-T1L's increased data transmission rate enables real-time monitoring and control of building systems, leading to greater operational efficiency. The response time, latency, and reliability of automation device communication are all improved by this technology.

10BASE-T1L Ethernet switch

Like the Ethernet standard, 10BASE-T1L provides switches for connecting various network segments and devices. Different network topologies may be constructed and utilized to power connected devices. In building automation, switches are often connected to controllers, sensors, and actuators. For greater availability, switches enable media redundancy in the form of ring topologies.

To this end, Analog Devices has developed the ADIN2111, a complete 10BASE-T1L Ethernet two-port switch designed for building automation networks (Figure 4). Adding long-range Ethernet connectivity to controllers, sensors, and actuators, the device is suitable for use within small, power-constrained edge devices. The ADIN2111 provides up to 50 percent savings in power consumption and up to 75 percent more PCB space than discrete implementations.

Figure 4: Block diagram of the ADIN2111. (Source: ADI)

Figure 4: Block diagram of the ADIN2111. (Source: ADI)

The ADIN2111 is designed for both in-line and ring daisy-chain networks, utilizing the existing single twisted pair cabling infrastructure within buildings, thus reducing retrofit costs. Figure 5 shows how several devices can be connected to implement both ring (upper side) and in-line (bottom side) topologies. Note that the last edge sensor is connected to a transceiver with PHY and MAC, whereas the other two are connected to a switch.

Figure 5: The ADIN2111 10BASE-T1L supports multiple topologies for maximum design flexibility and scalability. (Source: ADI)

Figure 5: The ADIN2111 10BASE-T1L supports multiple topologies for maximum design flexibility and scalability. (Source: ADI)

Equipped with a 16 address MAC lookup table, the 10BASE-T1L switch supports cut-through and store and forward operation, allowing users to prioritize latency or error handling when processing and forwarding data packets. Advanced packet filtering frees the burden of handling priority traffic from the processor.

The switch incorporates sophisticated diagnostic capabilities that reduce installation, commissioning, and system outages. Included among these are a link quality indicator with mean square error (MSE), link diagnostics and IEEE test modes, and cable defect detection using time domain reflectometry (TDR). This diagnostics solution is comprised of a highly accurate on-chip TDR engine and a set of algorithms that run on a host microcontroller, allowing for maximum flexibility for a broad range of cables and more advanced cable diagnostic capabilities.

Compliant with the IEEE 802.3cg standard, this solution supports Ethernet connectivity over 1.7 km of cabling, ring redundancy, and soft protocols including Modbus/TCP, BACnet/IP, and real-time KNX. It should also be noted that the ADIN2111 can be used as a repeater in an unmanaged configuration to extend reach up to and beyond 2,000 meters.

Conclusion

The introduction of 10BASE-T1L has created new opportunities for building automation, revolutionizing how commercial and residential spaces are managed and controlled. It is an ideal solution for implementing automation solutions due to its capacity to leverage existing infrastructure, provide flexibility, and improve data transmission.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.