Single-Pair Power over Ethernet Opens New Application Vistas

Contributed By DigiKey's North American Editors

2024-06-26

Power over Ethernet (PoE) has been available for years to deliver power over Ethernet cables, but its appeal has been restricted by a distance limitation of 100 meters or less. Now, there's a game-changer with single-pair power over Ethernet (SPoE), an IEEE-standardized technology that allows for power and data to be transmitted over long distances using a single twisted pair within an Ethernet cable, opening a new frontier for innovative applications.

Well-established and widely used for data communication between devices, Ethernet uses four pairs of twisted copper wires to carry data signals, with each pair carrying one direction of the data flow. Devices that use Ethernet also generally require a separate power supply, adding to wiring and installation costs.

Power over Ethernet (PoE) was developed as an extension to the Ethernet standard, allowing devices to receive both data and power over the same cable by using two pairs of wires to carry data and the other two for powering devices.

PoE can deliver up to 90 W of power over a maximum distance of up to 100 m. That has spawned PoE applications such as IP cameras, wireless access points, VoIP phones, and smart lighting systems that can be deployed and powered over a single cable. However, in addition to the distance limit, other PoE challenges include the need for bulky and expensive connectors and cables that can handle high currents and voltages, power losses, and heat dissipation.

Introducing SPoE

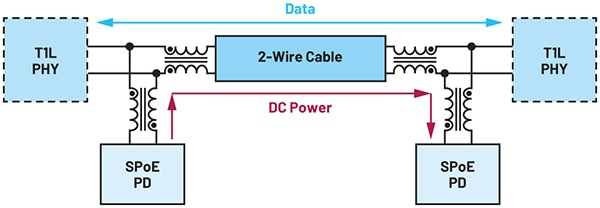

Using just one pair of wires to carry both data and power, SPoE can achieve data rates up to 1 Gbps and deliver up to 52 W of power over cable lengths up to 1 km (Figure 1), using smaller and cost-effective connectors and cables that are compatible with existing RJ45 sockets.

Figure 1: An SPoE system for transmitting up to 52 W of power. (Image source: Analog Devices)

Figure 1: An SPoE system for transmitting up to 52 W of power. (Image source: Analog Devices)

With reduced costs and simpler implementation, SPoE is well-suited for a wide range of applications in industrial, automotive, building automation, and IoT environments, where installing new cabling or relying solely on wireless LANs is either impractical, cost-prohibitive, or both. It provides comprehensive system telemetry for monitoring the energy transmission state, fault detection, and overvoltage protection.

In an industrial setting, SPoE can power sensors and control devices across long distances without having to add local power sources, simplifying network infrastructure, reducing installation costs, and providing central power management. It can be used to supply power over existing Ethernet cabling, making the addition of SPoE switches and endpoints a quick and relatively simple process.

SPoE is part of the IEEE 802.3 standard—IEEE 802.3 cg for 10 Mbps Ethernet over a single twisted pair (10Base-T1L)—providing an extension to the IEEE 802.3bu, Power over Data Lines (PoDL) standard. PoDL is used in systems up to 40 m and with 12, 24, or 48 volts; SPoE works with a voltage of 24 V or 55 V up to 1000 m.

SPoE is ideal for applications that need low to medium power and high data rates over long distances, which is not feasible or economical for PoE.

Potential applications for SPoE include:

- Operational technology systems where reliable communication and power delivery are critical for process control and automation

- Building and factory automation systems that can monitor and control environmental and machinery parameters

- Field instruments, such as sensors and actuators, that can be deployed with greater flexibility and less cost

- Security systems, such as for access control and surveillance, where SPoE scales more readily

- Traffic management systems that require consistent operation and connectivity

- Powering and managing IoT edge devices

- Remote power delivery for digital signage and outdoor lighting

SPoE design considerations

SPoE uses the "phantom power" technique to superimpose the power signal over the data signal on the same pair of wires, requiring complex controllers at each end of the cable to separate and regulate the power and data signals. Applications must also account for power losses and heat dissipation along the cable, which can affect the performance and reliability of the system.

A power sourcing equipment (PSE) controller provides sophisticated power management and conversion that ensures power delivery is safe, stable, and efficient. It works in combination with powered device (PD) controllers that receive energy over the 2-wire cable.

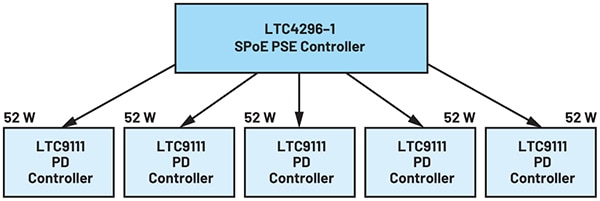

PSE controllers designed for multiple channels can power various remote devices, such as sensors. The LTC4296-1 (Figure 2) from Analog Devices, Inc. (ADI), for example, is a 5-port SPoE controller that can supply up to five loads with energy over five lines, each up to 1000 m in length. It delivers power using external, low drain-to-source on-resistance (RDS(ON)), N-channel metal-oxide-semiconductor field-effect transistors (MOSFETs), which minimize voltage drop and ensure application ruggedness.

Figure 2: ADI's 5-port LTC4296-1 power sourcing equipment (PSE) controller. (Image source: Analog Devices, Inc.)

Figure 2: ADI's 5-port LTC4296-1 power sourcing equipment (PSE) controller. (Image source: Analog Devices, Inc.)

The LTC4296-1 provides a versatile SPoE, PSE solution for 10BASE-T1L controllers and switches, and can easily be integrated with ADI'S 10BASE-T1L transceiver portfolio components, such as the ADIN2111CCPZ-R7 2-port device, which integrates a switch, two Ethernet physical layer (PHY) cores with a MAC interface and associated analog circuitry, a voltage supply monitoring circuit, and power-on reset (POR) circuitry. The transceiver provides direct connectivity with a variety of controllers via a serial peripheral interface (SPI).

At the other end, the LTC9111RDE#PBF is one of several PD controllers from ADI that provide a 2.3 V to 60 V operating range capability with polarity correction (Figure 3). The controller manages the classification and monitoring of the line transmission, driving two external N-channel MOSFET switches during classification with micropower operation to minimize reservoir capacitor requirements. An external N-channel MOSFET switch isolates the output capacitance from the connector during classification and inrush.

Figure 3: An LTC4296-1 SPoE PSE controller is suitable for driving up to five channels, here linked to LTC9111 PD controllers. (Image source: Analog Devices)

Figure 3: An LTC4296-1 SPoE PSE controller is suitable for driving up to five channels, here linked to LTC9111 PD controllers. (Image source: Analog Devices)

LTC9111 series controllers present a valid wake-up signature to the PSE to request power. IEEE 802.3cg compliant PSE and PD controllers perform the classification step using the Serial Communication Classification Protocol; the PSE ensures that the PD is compatible and, if so, proceeds to ramp the port voltage. If the operated electrical device needs a voltage other than 24 V or 55 V, an additional DC-to-DC converter is used.

ADI also provides the EVAL-SPoE-KIT-AZ evaluation kit for evaluating 10BASE-T1L data and SPoE power over a single twisted pair Ethernet (SPE) cable. The kit features the LTC4296-1 PSE controller and the LTC9111 PD for evaluation of IEEE 802.3cg Class 10 through 15 SPoE power and a 10BASE-T1L transceiver to provide data in the system.

Implementing SPoE applications

Product designers need to optimize the power budget and efficiency of their SPoE solutions, factoring in parameters including cable length, diameter, resistance, temperature, and environment.

Balancing power delivery with data transmission over a single twisted pair presents challenges, such as ensuring sufficient power for remote devices while maintaining data integrity over potentially long distances.

Power delivery on long cables at the 24 VDC supply voltage, common in many OT deployments, is subject to significant losses due to cable resistance. SPoE is specified in the IEEE 802.3cg standard to operate at a voltage of 24 V or 55 V, so designers can take advantage of increased power delivery efficiency near the maximum safety extra-low voltage (SELV) of 60 V.

Conclusion

SPoE is an emerging technology that enables simultaneous transmission of data and power over a single twisted pair in Ethernet cables. This can reduce the cost, complexity, and environmental impact of network infrastructures, as well as provide more flexibility, scalability, and reliability for connected devices. ADI's portfolio of IEEE 802.3cg-compliant PSE and PD controllers can simplify the design and implementation of SPoE applications with high efficiency and low noise, making them ideal for industrial, automotive, and smart building systems that require robust and reliable connectivity.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.