How to Use a Single Fieldbus Cable for Multiple Simultaneous Ethernet Protocols

Contributed By DigiKey's North American Editors

2023-11-28

The accelerating shift to Industry 4.0 and the Industrial Internet of Things (IIoT) brings the need for data collection and connectivity, enabling analysis to improve productivity and safety. However, horizontal and vertical data collection and transfer throughout a factory can be complex and costly, especially where multiple networks and harsh environments are involved. Designers need a way to efficiently design, deploy, and manage industrial networks that can exchange data with multiple programmable logic controllers (PLCs), sensors, and actuators from different vendors, while simultaneously using different protocols and minimal wiring.

This can be accomplished using an integrated and optimized distributed input/output (I/O) platform that can handle multiple protocols over a single Ethernet cable. Such a system also enables industrial network operators to simplify service requirements and reduce the spare parts inventory by standardizing on a single I/O platform, regardless of the PLC being used.

This article provides a brief review of Industry 4.0 networks. It then introduces an I/O platform from Siemens that accommodates multiple Ethernet fieldbuses on a single cable in harsh environments, and shows how it can be used to meet the needs of Industry 4.0 designers.

Ethernet protocols

Industry 4.0 deployments have a variety of communication needs. Each of the three main fieldbus protocols, PROFINET, EtherNet/IP, and Modbus TCP, supports different use cases from operation technology (OT) on the factory floor to information technology (IT).

PROFINET: This is a deterministic high-performance protocol used for data exchange between controllers like PLCs and devices. It is suitable for real-time and safety-critical functions that include high-speed motion control applications. It is also used for integrating OT/IT functions.

EtherNet/IP: This uses the standard Ethernet protocol, making it easy to implement with Ethernet devices. The Common Industrial Protocol (CIP) is optimized for industrial automation applications and supports network technologies including EtherNet/IP. EtherNet/IP can also be used for data exchange from the field level to IT systems.

Modbus TCP: This is a TCP/IP-based protocol that is useful for non-time-critical functions like energy consumption and environmental data collection, as well as data exchanges between the field level and IT systems.

Given that each of the three fieldbuses has a specific purpose, all three are needed. This creates complex communication challenges, which is where MultiFieldbus systems come in. The MultiFieldbus communications controller sits between the field level and the control level, simultaneously communicating with multiple controllers using different protocols over a single network cable (Figure 1). MultiFieldbus devices can be found in a range of environments, from inside a protected control cabinet to outside on the factory floor to remote outdoor installations.

Figure 1: A MultiFieldbus communications controller sits between the field level and the control level, facilitating comprehensive Industry 4.0 connectivity and communication. (Image source: Siemens)

Figure 1: A MultiFieldbus communications controller sits between the field level and the control level, facilitating comprehensive Industry 4.0 connectivity and communication. (Image source: Siemens)

Diverse environments

Environmental diversity requires devices with a variety of ingress protection (IP) ratings from IP20 to IP67. The IP rating system is embodied in International Electrotechnical Commission (IEC) standard 60529 and rates devices based on their enclosure’s ability to provide protection against the intrusion of dust and liquids, and how easily hazardous parts of the enclosed system can be accessed by fingers, tools, or solid objects of various sizes. IP codes consist of two digits. The first indicates the protection against solid objects and is rated on a scale from 0 (no protection) to 6 (no ingress of dust). The second digit indicates the protection against liquids and is rated from 0 (no protection) to 9 (protection from hot water at high pressure from different angles).

For example, IP20 rated devices are useful inside control cabinets or similar environments. The 2 indicates protection from particles > 12.5 millimeters (mm), like fingers or similar objects, and the 0 indicates no protection against ingress of water.

For more challenging environments, typical IP ratings include IP65, IP67, and IP69K where the 6 indicates a sealed and completely dustproof enclosure. These IP ratings provide varying protection against water.

- IP65 indicates that water projected by a nozzle (6.3 mm) against an enclosure from any direction shall have no harmful effects.

- IP67 indicates that an ingress of water in a harmful quantity shall not be possible when the enclosure is immersed in water up to 1 meter (m).

- IP69K is for equipment used in road vehicles and applies to high-pressure, high-temperature wash-downs.

MultiFieldbus platform

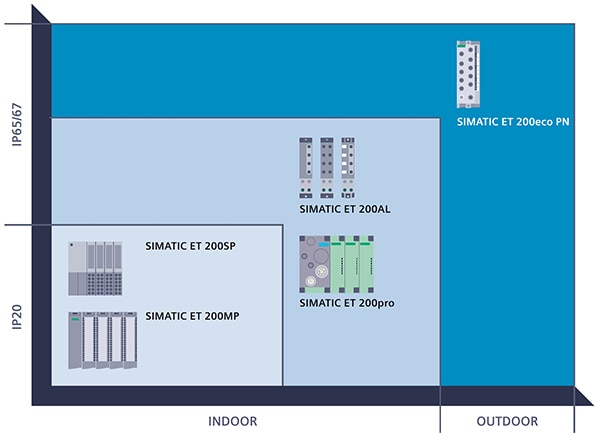

Siemens’ SIMATIC ET 200 I/O MultiFieldbus platform and interface modules can simultaneously exchange data with multiple controllers using PROFINET, EtherNet/IP, and Modbus TCP protocols over the same cable. The communication protocols are all configurable via software with no change in hardware. The complete SIMATIC ET 200 I/O platform with MultiFieldbus also includes modules with IP20 ratings for use in control cabinets, modules with IP65 and IP67 for indoor use on machines, and IP69K for outdoor use (Figure 2).

Figure 2: The SIMATIC ET 200 I/O MultiFieldbus platform includes several device families and can support Industry 4.0 installations in control cabinets, indoors on machines, and outdoors. (Image: Siemens)

Figure 2: The SIMATIC ET 200 I/O MultiFieldbus platform includes several device families and can support Industry 4.0 installations in control cabinets, indoors on machines, and outdoors. (Image: Siemens)

The system can support simultaneous communication with up to six PLCs using different fieldbus protocols. In addition, there are modules for IO-Link, Profibus, point-to-point (PtP), controller area network (CAN), actuator sensor interface (Asi), digital addressable lighting interface (DALI), and digital multiplexer DMX512. Standard and failsafe I/O can be mixed on a single station.

The system’s multifunctional and modular architecture supports mass customization, a hallmark of Industry 4.0 factories. Rapid wiring is supported with push-in terminals, and modules are available for a range of functions like counting, energy monitoring, motor starters, position inputs, servo drives, temperature sensing, time-based I/O, and even electric vehicle charging. Many of the modules support PROFIenergy, a profile of the PROFINET communications protocol that enables power management in industrial automation devices.

The SIMATIC ET 200SP is a multifunctional and scalable distributed I/O system with a wide variety of modules. For example, model 6ES71556MU000CN0 is a two-port interface module for use inside control cabinets (Figure 3), and model 6ES71936BP000BA0 is a SIMATIC ET 200SP base unit with a particularly small footprint that is designed for installation in small control boxes next to machines. Both have an IP20 rating and an operating temperature range of -30°C to +60°C.

Figure 3: The 6ES71556MU000CN0 is a two-port interface module for use inside control cabinets. (Image source: Siemens)

Figure 3: The 6ES71556MU000CN0 is a two-port interface module for use inside control cabinets. (Image source: Siemens)

Vibration-tolerant modules for assembly lines

The SIMATIC ET 200AL has been optimized for applications involving motion like automated and semiautomated assembly lines (Figure 4). The modules can handle vibrations up to 5 g continuously with a 10 g maximum. They are IP65/67 rated with an operating temperature range of -25°C to +55°C, and their compact and lightweight design suits distributed control applications on machines. They are available with module widths of 30 mm or 45 mm and support up to 32 modules per station. The modules support the integration of sensors and actuators using M8 or M12 connectors depending on the module. They also feature PROFIenergy functionality.

Figure 4: ET 200AL modules (lower right corner) are optimized for applications involving motion and can handle vibration up to 5 g continuously. (Image source: Siemens)

Figure 4: ET 200AL modules (lower right corner) are optimized for applications involving motion and can handle vibration up to 5 g continuously. (Image source: Siemens)

Examples of ET 200AL modules include:

- The 6ES71415BF000BA0, has eight digital inputs and M8 sockets for connecting proximity sensors and switches. It measures 30 mm x 159 mm.

- The 6ES71445KD500BA0, has eight analog inputs and M12 sockets for connections. Measurement types can be programmed for each channel including voltage, current (2- and 4-wire transducers), resistance (2- and 3-wire transducers), and resistance thermometer detectors (2- and 3-wire connections). It has 16-bit resolution and measures 30 mm x 159 mm.

IP65/67-rated modules for machine mounting

SIMATIC ET 200pro modules are rated for IP65/67 and designed for installation outside a control cabinet, directly at a machine. With a wireless connection, these modules are well-suited for use in applications like automated guided vehicle systems, building management, warehouse logistics, and electric monorail systems. The family can be hot-swapped and includes central processing unit (CPU) modules, interface modules, I/O modules, and functional modules.

The ET 200pro series includes a range of functions like IO-Link and radio frequency identification (RFID). Motor starter modules can be used for starting and protecting motors and loads up to 5.5 kilowatts (kW). Fail-safe versions are available that can support safety integrity level (SIL) 3. The frequency converter module can be used for open or closed-loop control of induction motors. The 6ES71444JF000AB0 temperature measuring module is highly flexible and can be programmed to use a range of resistance temperature detectors (RTDs) including Pt100, PT200, PT500, Pt1000, NI100, NI200, NI500, and NI1000, and it can output the temperature as Celsius or Fahrenheit.

Machine-mount modules for outdoor and hazardous areas

SIMATIC ET 200eco PN modules provide a compact block I/O with IP65 and IP67 ratings and are suitable for cabinet-free installation directly at a machine. Like all ET 200 modules, they support PROFINET, Ethernet/IP, and Modbus TCP. These modules come in a fully sealed, zinc die-cast housing and are resistant to vibration, dust, oil, and humidity, making them suitable for outdoor installations. They have an operating temperature of -40°C to +60°C. The ET 200eco PN series is approved by the European Union (EU) Atmospheres Explosibles (ATEX) directive and can be used in hazardous areas up to zone 2.

For devices compliant with the IO-Link V1.1 specification, device and master parameters can be automatically transferred using the ‘autostart function’ without any previous configuration if a device needs to be replaced. For example, module 6ES71486JG000BB0 can operate as an IO-Link V1.1 master device and includes a mix of 4 Class A and 4 Class B IO-Link ports (Figure 5). The ports can function as digital inputs or outputs depending on the parameter assignments. It is rated for IP67 and IP69K, and it supports three transmission rates: 4.8 kilobaud (kBd) on COM1, 38.4 kBd on COM2, and 230.4 kBd on COM3.

Figure 5: The SIMATIC ET 200eco PN module (left) and a closeup of a typical installation (right) (Image source: Siemens)

Figure 5: The SIMATIC ET 200eco PN module (left) and a closeup of a typical installation (right) (Image source: Siemens)

Conclusion

Deploying Industry 4.0 networks is a complex endeavor that must account for multiple communication interfaces and varying operating environments. To streamline factory networks, designers can use Siemens’ SIMATIC ET 200 MultiFieldbus platform to simultaneously exchange data with up to six PLCs using PROFINET, EtherNet/IP, and Modbus TCP protocols over the same cable.

Recommended reading

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.