How to Select and Apply Radar for Sensing in Harsh Environments

Contributed By DigiKey's North American Editors

2024-09-25

Outdoor and industrial applications and other rugged environments present conditions that can interfere with remote sensing technologies such as ultrasonic sensors. Inclement weather, dust and debris, and complex sensing environments are some issues that can impact standard sensors.

Radar sensors can address these challenges, detecting moving and stationary targets in various ambient conditions. This article reviews the scenarios where radar can outperform alternative options. It examines several types of radar sensors from Banner Engineering, their applications, and design considerations to remember when selecting a sensor.

Why use radar sensors?

Radar is robust in the face of rain, dust, and other common airborne substances, works equally well in bright and unlit spaces, and is unaffected by temperature variations and wind. It can detect surfaces with a wide range of finishes, geometries, and colors, and also penetrate non-conductive materials, allowing radar sensors to peer inside containers.

In addition, radar can be used over relatively long distances while also being resistant to crosstalk, giving it advantages for short-range applications where sensors are in close proximity.

How radar works

Radar works by bouncing electromagnetic waves off target objects, determining distance based on the time it takes for a signal to return. Radar sensors use two main technologies: frequency-modulated continuous wave (FMCW) and pulsed coherent radar (PCR).

FMCW radar emits a constant stream of radio waves, allowing for uninterrupted monitoring of moving and stationary objects. PCR sensors send radio waves in pulses, typically using low-power transmitters. This makes PCR sensors better suited to short-range applications.

Range and material sensitivity are also heavily influenced by the operating frequency. Lower frequencies are better for long-range detection and work well with materials that have high dielectric constants, such as metals and water. Higher frequencies offer greater accuracy and are better suited for detecting smaller objects and a wider variety of materials.

Beam patterns and sensing zones

Radar sensors can be optimized to focus on specific areas of interest and track one or multiple objects. Key parameters include the beam pattern, sensing zones, and dead zones.

Radar sensors emit radio waves in a specific pattern, defined by horizontal and vertical angles. Narrow beam patterns offer precise detection and longer range, while wide beam patterns cover larger areas and better detect irregularly shaped objects.

Many radar sensors allow the configuration of multiple sensing zones within their beam pattern. This feature enables more complex detection scenarios, such as setting different parameters for near and far zones in collision avoidance applications.

The dead zone is the area immediately in front of the sensor where detection is unreliable. Higher-frequency sensors generally have shorter dead zones.

Identifying the optimal radar sensor: start with the basics

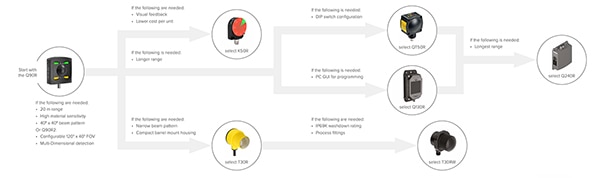

There are numerous factors to consider when selecting a radar sensor. In addition to the basic operating parameters, radar sensors have various features that impact their cost, durability, and ease of use. Figure 1 provides a flow chart that illustrates some of these decision points using radar sensors from Banner Engineering as examples.

Figure 1: Shown is a flowchart that illustrates the process of choosing a radar sensor. (Image source: Banner Engineering)

Figure 1: Shown is a flowchart that illustrates the process of choosing a radar sensor. (Image source: Banner Engineering)

The Q90R series from Banner Engineering is a useful starting point. These FMCW sensors operate at 60 gigahertz (GHz) to balance range, accuracy, and material detection capabilities. They have a sensing range of 0.15 meters (m) to 20 m, a dead zone of 150 millimeters (mm), and two configurable sensing zones.

An example use case for these sensors is detecting when trucks arrive at a loading dock. Here, the relatively wide 40° x 40° beam pattern makes it easier to find a mounting location that keeps the dock in view.

The Q90R2-12040-6KDQ (Figure 2) builds on these capabilities with a wide, configurable field of view (120? x 40?) and the ability to track two targets, allowing them to tackle more complex sensing scenarios.

Figure 2: The Q90R2-12040-6KDQ FMCW radar sensor operates at 60 GHz, can track two targets, and has a wide, configurable field of view. (Image source: Banner Engineering)

Figure 2: The Q90R2-12040-6KDQ FMCW radar sensor operates at 60 GHz, can track two targets, and has a wide, configurable field of view. (Image source: Banner Engineering)

Selecting radar for narrow beam applications

In some applications, radar needs to pick out a small target. Here, a sensor from the T30R series (Figure 3) is a good choice. The sensors have a beam pattern of 15° x 15° or 45° x 45°, an operating frequency of 122 GHz, a sensing range of 25 m, a dead zone of 100 mm, and two configurable sensing zones.

With its narrow beam pattern and high operating frequency, this sensor family offers precise detection in specific areas. For example, they can be used to monitor levels within narrow containers.

Figure 3: The T30R series operates at 122 GHz, has a beam of 15° x 15°, and offers precise detection. (Image source: Banner Engineering)

Figure 3: The T30R series operates at 122 GHz, has a beam of 15° x 15°, and offers precise detection. (Image source: Banner Engineering)

The T30RW version comes in an IP69K housing suitable for high-pressure, high-temperature wash-down environments such as car washes. It has a sensing range of 15 m and a beam pattern of 15° x 15°.

Selecting a radar sensor for visual feedback

While radar sensors typically integrate into larger automation systems, having an at-a-glance status indicator can be helpful. At an electric vehicle (EV) charging station, for example, a visual display can help drivers correctly position their vehicles.

For applications like these, the built-in LEDs of the K50R series play a valuable role.

Particularly noteworthy are the Pro models, like the K50RPF-8060-LDQ (Figure 4), which offers a colorful, easy-to-interpret display.

Figure 4: The K50RPF-8060-LDQ incorporates LEDs for visual feedback. (Image source: Banner Engineering)

Figure 4: The K50RPF-8060-LDQ incorporates LEDs for visual feedback. (Image source: Banner Engineering)

Key specifications for the K50R series include an operating frequency of 60 GHz, a sensing range of 5 m, a dead zone of 50 mm, two configurable sensing zones, and beam patterns of 80° x 60° or 40° x 30°.

Selecting a long-range radar sensor

For applications that require sensing over longer distances, radar operating at 24 GHz is often the best choice. These lower-frequency devices, such as the QT50R series, have a sensing range of 25 m that is valuable for applications such as collision avoidance for mobile equipment. The series also has one or two configurable sensing zones and a beam pattern of 90° x 76°. Its dead zone measures 400 mm for moving objects and 1000 mm for stationary objects.

A notable feature of the QT50R is its ability to be configured through DIP switches. This enables simple setup in the field. However, some applications call for more sophisticated configurations.

For example, the Q130R sensor (Figure 5) is designed for applications requiring sophisticated detection capabilities and advanced configuration options. It operates at 24 GHz, has a range of 40 m, a beam pattern of 90° x 76° or 24° x 50°, a dead zone of 1000 mm, and provides accurate detection of moving and stationary objects.

Figure 5: The Q130R radar sensor is designed for applications requiring sophisticated detection capabilities and provides accurate detection of moving and stationary objects. (Image source: Banner Engineering)

Figure 5: The Q130R radar sensor is designed for applications requiring sophisticated detection capabilities and provides accurate detection of moving and stationary objects. (Image source: Banner Engineering)

Notably, the Q130R employs a PC-based graphical user interface (GUI) for complex setup and fine-tuning. For example, it can be used for positioning feedback in a busy rail yard. In this application, the sensor can be configured to ignore trains parked in the background on one track while recognizing other trains as they pass in front.

Conclusion

Radar sensors are uniquely capable of operating in a wide range of outdoor and harsh environments. To maximize the benefits of radar technology, it is essential to analyze the application requirements and select a sensor with the right operating frequency and beam pattern, among other specifications. With a well-chosen radar, many challenging remote sensing applications can be addressed.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.