How to Quickly Design and Deploy IIoT-Ready Machines

Contributed By DigiKey's North American Editors

2024-08-14

Rapidly designing and deploying machines ready for integration into the Industrial Internet of Things (IIoT) is challenging. IIoT-enabled machines must support fast commissioning of machine-to-machine, machine-to-plant, and machine-to-cloud communication and coordination.

That demands a comprehensive solution. It needs to include a complete array of control, interface, and communication modules. Scalability is a must. It should support simplified installation for rapid deployment. Finally, it must easily integrate into a multi-vendor environment to support legacy equipment.

The reward is greater operational efficiency across all levels of the organization and throughout the machines’ lifecycles.

This article reviews how the motor control options from Schneider Electric provide designers with end-to-end automation solutions. It presents the features and benefits of Altistart soft starters, Altivar drives, Modicon Ethernet switches and programmable logic controllers (PLCs), Harmony control relays, and PowerPacT circuit breakers.

It then details how the TeSys island system elements support comprehensive solutions and integrates easily with Rockwell Studio 5000 and Siemens TIA Portal environments to support legacy machines and closes by looking at how Schneider Electric’s EcoStruxure Machine Expert software speeds development, configuring, and commissioning of IIoT ready machines.

Motion is a basic characteristic of industrial machines. It is implemented in various ways, from simple motion profiles in systems like pumps, conveyors, and cranes to complex motion profiles in process and assembly operations and robotics.

Machines with simple motion profiles can benefit from the features found in soft starters like the Altistart soft starter family. Altistart soft starters support the following:

- Controlled acceleration that reduces mechanical shocks that can increase wear and tear and lead to increased maintenance needs and machine downtime

- Limiting inrush currents to reduce energy use

- Protecting motors from power surges that can happen during startup, improving motor lifetimes

- Higher reliability by detecting faults such as a blocked motor, underload, or incorrect earthing and sending an alert to machine operators

Basic machines that don’t need high starting torque can turn to the ATS01 series soft starters. Activating the BOOST logic input enables the application of a voltage boost equal to 100% of the nominal motor voltage for 200 milliseconds (ms) to overcome initial mechanical friction in the system. The programmed voltage ramp-up begins following the boost.

The model ATS01N232RT is for soft starting and stopping three-phase asynchronous motors up to 15 kilowatts (kW) (20 horsepower (hp)) with acceleration and deceleration times from 1 to 10 seconds. It’s optimized for simple belt-driven applications like pumps, compressors, and fans operating from 440 VAC to 480 VAC. Controls are on the front panel to set the start time, initial voltage, and stop time for installation and commissioning.

Designers of more demanding process and infrastructure machines like mixers, crushers, and conveyors can turn to the Altivar ATS480 series of soft starters. While simpler soft starters employ voltage ramps, the ATS480 soft starters use a softer torque ramp and can implement a braking function.

The model ATS480C11Y operates with voltages from 208 VAC to 690 VAC (Figure 1). Depending on motor voltage, it can be used with motors from 22 to 90 kW (25 to 100 hp). It has a Modbus serial communication port with an RJ45 connector. Optional communication cards are available for Profibus, PROFINET, Modbus TCP/EtherNet/IP, and CANopen.

Figure 1: This Altivar Soft Starter is designed for use with asynchronous motors from 22 to 90 kW. (Image source: DigiKey)

Figure 1: This Altivar Soft Starter is designed for use with asynchronous motors from 22 to 90 kW. (Image source: DigiKey)

Driving more advanced machines

Complex motion profiles in advanced machines can be supported using variable frequency drives (VFDs) like the Altivar 320 family with units rated from 0.18 to 15 kW (0.25 to 20 hp) for applications like material handling, packaging, textiles, hoisting, mechanical actuators, and material working. The ATV320U75M3C is rated for 7.5 kW and operates from a supply voltage of 200 VAC to 240 VAC.

To speed up configuration and commissioning, these drives feature 150 functions and are standard and customizable configurations. There are dedicated functions for applications like material handling, textiles, hoisting, and mechanical actuators.

Altivar 320 VFDs can provide high-performance control of asynchronous and permanent magnet motors, including torque and speed accuracy at very low speeds and dynamic motion with flux vector control without a sensor. When used with three-phase synchronous and asynchronous motors, these VFDs feature:

- Support of high-speed motors

- Static speed accuracy for open-loop synchronous motors

- Flexible system integration options, including Ethernet, CANopen, Profibus, EtherCAT, DeviceNet, and more

- Integrated safety functions that comply with functional safety standards

- Formats like compact and book drives with degrees of protection from IP20 to IP66 support integration into different types of cabinets (Figure 2)

Figure 2: Altivar 320 VFDs are available in various form factors to simplify installation and maximize space utilization in equipment cabinets. (Image source: DigiKey)

Figure 2: Altivar 320 VFDs are available in various form factors to simplify installation and maximize space utilization in equipment cabinets. (Image source: DigiKey)

High-performance multi-axis machines

Modicon Ethernet switches and programmable logic controllers (PLCs) can support high-performance designs from a single independent axis to high-performance synchronized multi-axis machines requiring high-speed and precise positioning and movements like robotics.

These IIoT native edge controllers can connect directly to the cloud using Message Queuing Telemetry Transport (MQTT), Open Platform Communications Unified Architecture (OPC UA) server and client, and Transport Layer Security (TLS) encryption and have embedded safety and cybersecurity functions. The dual Ethernet port can support Ethernet/IP and Modbus TCP protocols. There are also RS232 and RS485 ports, a USB port, and a slot for an SD card.

TM262L controllers are for logic control of multiple input/output arrangements, including four fast digital inputs and four fast digital outputs. The model TM262L10MESE8T has an execution speed of 5 nanoseconds (ns) per instruction. The dual-core processor efficiently manages parallel applications and communication (Figure 3).

Figure 3: This Modicon M262 PLC supplies IIoT-ready machine-to-cloud and machine-to-plant Ethernet connectivity. (Image source: DigiKey)

Figure 3: This Modicon M262 PLC supplies IIoT-ready machine-to-cloud and machine-to-plant Ethernet connectivity. (Image source: DigiKey)

The TM4 bus on the Modicon M262 family supports up to 3 communication expansion modules. Profibus DP (TM4PDPS1) and Ethernet (TM4ES4) expansion modules can be used in various combinations to a maximum of three modules.

Nixing abnormalities

Sometimes, machines, including IIoT-ready machines, must be protected from abnormal conditions. That’s where Harmony Control Relays come in. They can monitor both electrical and mechanical conditions and identify abnormalities related to current, voltage, phase, frequency, speed, temperature, pump control, and even liquid level.

Quick and accurate identification of abnormalities can increase uptime and reduce the need for unscheduled maintenance in applications like pumping, water processing, hoists and lifts, packaging systems, and textile machines. Harmony Control Relays are available with a wide range of functions to suit specific application needs.

Model RMNF22TB30 is a three-phase relay with integrated near-field communications (NFC). It can monitor seven parameters: phase loss, phase sequence, asymmetry, undervoltage, overvoltage, under-frequency, and over-frequency. Using the NFC app, designers can use AND, OR, and NOT logic to form custom monitoring combinations for the two individually configurable relay outputs.

For simpler machines that only need overvoltage monitoring, designers can turn to the RM22UA21MR (Figure 4). This single-phase control relay includes a selectable memory function and an integral LED indicating control status. The screw trimmers enable simple and precise threshold settings, and it provides automatic shutdown management and fault information for quick fault identification and troubleshooting.

Figure 4: Single-phase overvoltage control relay with a switching capacity of 2 kVA. (Image source: DigiKey)

Figure 4: Single-phase overvoltage control relay with a switching capacity of 2 kVA. (Image source: DigiKey)

Basic protection

Applications that can benefit from more basic protection can turn to PowerPacT Circuit Breakers rated from 15 to 125 A and available with one-, two-, three-, and four-poles. These thermal magnetic circuit breakers have positive contact indication and deliver isolation in compliance with IEC/EN60947-1 and IEC/EN60947-2 standards for “low-voltage switchgear and control gear.”

Model BDF16020 is a 20 A single-pole unit with a rated operational voltage of 240 VAC 50/60 Hz according to UL 489. Its continuous current rating is 80% of the maximum rating, and it is rated “service breaking” according to IEC 60947-2 (Figure 5). The VisiTrip LED readout makes it easier to see which circuit breaker has tripped in the enclosure or panel. It also has a QR code to access information, including the instruction manual, part numbers, and CAD drawings.

Figure 5: Circuit breakers like this offer positive contact indication and meet the isolation requirements of IEC/EN60947. (Image source: DigiKey)

Figure 5: Circuit breakers like this offer positive contact indication and meet the isolation requirements of IEC/EN60947. (Image source: DigiKey)

Integrated fieldbus nodes

TeSys is a digitized IIoT-connected load management solution that acts as an integrated node in a Fieldbus network and includes the modules needed to implement an IIoT-ready machine. It’s based on multifunctional devices and avatars for industrial applications with loads up to 80 amps and can speed design, wiring, and commissioning times.

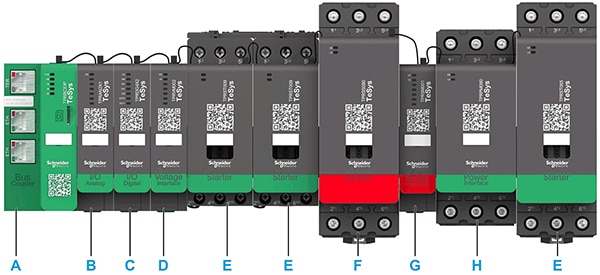

A bus coupler like the TPRBCEIP is the core module that provides internal communication with the TeSys island modules via ribbon cables. It’s also the connection point between a TeSys island and an external automation system using EtherNet/IP or Modbus TCP communication. An embedded web server supports diagnostics and maintenance. It includes one RJ45 service port over Ethernet, a micro SD card port, and a port for the internal bus interconnecting the modules of the island. A typical configuration includes (Figure 6):

- Bus coupler

- Analog input / output module

- Digital input / output module

- Voltage interface module

- Standard starters

- Safety integrity level (SIL) starter

- SIL interface module

- Power interface module

Figure 6: The combined units in the TeSys island act as a single node in a Fieldbus network. (Image source: Schneider Electric)

Figure 6: The combined units in the TeSys island act as a single node in a Fieldbus network. (Image source: Schneider Electric)

Exemplary TeSys island modules include:

- LC1DT406BL 40 A, 4-pole, normally open, TeSys Deca contactor with IEC60335-1 compliance for industrial and HVAC systems

- LC1G115EHEN 150 A (75 kW at 440 VAC), 3-pole, normally open, TeSys Giga contactor, designed for use in demanding applications with operating rates of up to 600 cycles per hour and operating temperature up to +60°C

- TPRDG4X2 digital I/O module with four digital inputs and two digital outputs can manage motors and other electrical loads up to 65 A (37 kW, 40 hp). All adjustments and settings are digitized, and no mechanical dials or dip switches

- TeSys island Communicating Motor Starters rated up to 40 hp (80 A at 480 V). These SIL starters meet the requirements of IEC 61508, IEC 62061, and ISO 13849-1 and support PL d, and SIL 2

TeSys island also supports comprehensive solutions and integrates easily with Rockwell Studio 5000 and Siemens TIA Portal environments to support legacy machines.

Putting it all together

When it’s time to build the completed machine, designers can turn to the EcoStruxure Machine Expert. This software solution supports development, configuration, commissioning, operation, and maintenance of IIoT-ready machines.

EcoStruxure Machine Expert can handle all the latest IIoT machine building blocks, including Modicon M262 PLCs and the TeSys Island digital load management system. It’s designed to deliver machines optimized for safety, reliability, efficiency, connectivity, and sustainability. It leverages the IIoT with mobility, sensing, cloud, analytics, and cybersecurity solutions to accomplish that complex task.

Conclusion

IIoT-enabled machines are an important aspect of Industry 4.0 operations. Designing, commissioning, and integrating those machines are complex tasks. Schneider Electric supplies machine designers with a comprehensive suite of devices and software tools for IIoT-enabled machines that deliver improved operational efficiency across all levels of the organization and throughout the machines’ lifecycles.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.