Driving Efficiency and Sustainability in Industries with Motion and Control Solutions

Contributed By DigiKey

2024-05-24

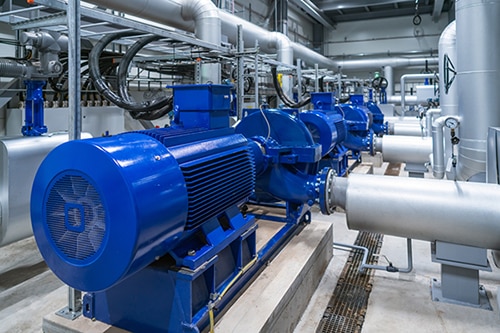

Figure 1: Water pumps in a large power plant. (Image source: Shutterstock)

Figure 1: Water pumps in a large power plant. (Image source: Shutterstock)

In the face of environmental challenges and the need for sustainable electronics, industries across the globe are seeking solutions to optimize their operations and minimize their carbon footprint. No matter the industry, there is a need to control processes to lower energy usage, minimize waste, and maximize output.

Motion and control products work together to manage the movement, speed, and position of mechanical elements within electronic applications. These products are designed to provide precise, efficient, and reliable control over various aspects of motion, enabling machines and equipment to perform their functions with optimal performance and minimal error.

DigiKey, a global distributor of electronic components, offers a broad selection of motion and control products from multiple suppliers, allowing customers to improve the sustainability and efficiency of their automated systems.

Core components of motion and control systems

At the heart of motion and control solutions are electric motors, which serve as the primary means of converting electrical energy into mechanical energy. There are several types used in applications, each with unique characteristics and advantages. For example, AC motors are known for their durability, efficiency, and ability to operate at high speeds, making them suitable for use in industrial machines, HVAC systems, and other applications where reliable, long-term performance is essential. DC motors, on the other hand, offer excellent torque and speed control, making them well-suited for applications that require precise movement, such as robotics and automotive systems. Stepper motors provide highly accurate positioning and are used in 3D printers, CNC machines, and other devices that demand precise, incremental motion. Servo motors, with their fast response times and high torque output, are employed in applications that require quick, accurate movements, such as aerospace systems.

To effectively control and regulate the operation of motors, motion and control solutions rely on a variety of drives and controllers. Variable frequency drives (VFDs) are used to manage the speed and torque of AC motors, enabling smooth, efficient operation and energy savings. Servo drives, specifically designed for servo motors, provide closed-loop control and enable highly precise positioning and motion. Motion controllers, capable of handling multiple axes of motion simultaneously, are employed in complex applications where they coordinate and synchronize the movement of various components for smooth and accurate operation.

Actuators also serve a crucial role in motion and control systems, as they are responsible for converting energy into motion and providing force to move mechanical components. Known for their high force output and ability to handle heavy loads, hydraulic actuators are utilized in construction equipment, industrial machinery, etc., where raw power is required. Pneumatic actuators, which rely on compressed air to generate motion and provide fast response times, are utilized in applications that involve quick, repetitive movements, such as packaging and assembly lines. Electric actuators, including linear and rotary types, provide precise control in applications such as medical, automotive, and aerospace devices and equipment.

Figure 2: Robotic vision sensor camera system in a smart factory. (Image source: Shutterstock)

Figure 2: Robotic vision sensor camera system in a smart factory. (Image source: Shutterstock)

Sensors, feedback devices, and control systems

To ensure that motion and control systems operate with the highest level of accuracy and reliability, sensors and feedback devices are used to monitor and measure various aspects of motion. Position sensors, such as linear and rotary potentiometers, provide real-time data on the exact location of mechanical elements, allowing for precise positioning and tracking. Encoders, such as incremental and absolute, are used to determine the angular position and velocity of rotating shafts, enabling accurate speed and position control. Resolvers, similar to encoders but designed for use in harsh environments, also offer high accuracy and reliability in sensitive applications.

Tying all these components together are the control systems that orchestrate and manage the overall operation of motion and control solutions. Programmable logic controllers (PLCs), rugged industrial computers designed for control and automation, handle multiple input and output signals simultaneously in factory automation, process control, and other applications. Industrial PCs, which offer greater flexibility and processing power than PLCs, are often used in tandem with advanced motion control software to simulate motion control algorithms in complex, multi-axis systems.

Motion and control components in industrial applications

Motion and control solutions are crucial for enhancing efficiency, accuracy, and productivity in a broad range of industrial processes. For example, they manage equipment such as robotic arms and machine tools to enhance industrial operations and minimize errors. In automotive factories and warehouses, motion and control systems coordinate the movement of industrial robots, collaborative robots (cobots) and autonomous mobile robots (AMRs) to perform tasks like handling, assembly, and inspection. Similarly, in industrial packaging applications, motion and control solutions pick and transport items like boxes and pallets using conveyor systems, sorting machines, and automated storage/retrieval systems (AS/RS).

In the medical sector, motion and control systems shape the way healthcare is delivered and research is conducted. They enable precise positioning, dosing, and automation in medical devices and equipment, such as surgical robots, diagnostic imaging systems, and laboratory instrumentation. For example, surgical robots equipped with motion and control components can perform procedures with accuracy and minimal invasiveness, reducing patient recovery times and improving overall outcomes. Automated liquid handling systems in pharmaceutical research labs also use motion and control systems to accurately dispense and mix reagents, streamlining the drug discovery process and accelerating the development of new therapies.

The aerospace and defense industries also depend on precision motion and control solutions for mission-critical applications like satellite positioning, aircraft control systems, and missile guidance. In these sectors, even the slightest deviation from the intended motion or position can have a catastrophic impact. Motion and control technologies ensure that these systems operate with exceptional accuracy and reliability, allowing satellites to maintain orbits, aircraft to fly safely, and missiles to reach targets. Moreover, these solutions enable the development and testing of new aerospace and defense technologies, allowing engineers to simulate and validate complex systems before they are deployed in the field.

Understanding DigiKey's multi-supplier strategy

By partnering with multiple suppliers, DigiKey ensures engineers and system designers have access to a broad selection of products. This strategy not only increases product variety but also improves availability, promotes competitive pricing, and provides access to a wealth of technical expertise. One clear advantage of DigiKey's multi-supplier approach is the ability to cater to a host of industrial requirements. Whether it's a compact stepper motor for precision instrumentation or a high-torque servo drive for heavy-duty automation, DigiKey's inventory offers a solution for all applications. This diversity enables engineers to find the most suitable products for their specific needs that can optimize overall system performance and efficiency. Moreover, by sourcing from multiple suppliers, DigiKey minimizes the risk of supply chain disruptions – when one manufacturer is experiencing production issues or delays, alternative products from other suppliers can be sourced, ensuring a reliable and consistent supply for customers. This resilience makes all the difference in industrial facilities where even minimal downtime can have a significant impact on resources, budgets, and operations.

Advanced motion and control products from industry leaders

DigiKey's partnerships with leading manufacturers such as Schneider Electric, Siemens, and Omron shows its commitment to quality and innovation. These industry giants are renowned for their cutting-edge motion and control solutions, which incorporate advanced features and technologies to drive efficiency and sustainability.

Schneider Electric’s Altivar™ Soft Starter ATS480 (Figure 3) builds on the start/stop performance of previous iterations to further extend equipment lifetimes and maximize application availability in demanding environments. The Altivar 212 VSD provides maximum ease of use and security for system integrators and end-users in HVAC systems, saving energy and enhancing building comfort and management. Similarly, ATV320 VFDs provide safety, reliability, and simplicity in compact form factors for simplified installation and efficient use of space.

Figure 3: Schneider Electric Altivar™ Soft Starter ATS480. (Image source: Schneider Electric)

Figure 3: Schneider Electric Altivar™ Soft Starter ATS480. (Image source: Schneider Electric)

Schneider Electric’s Easy TeSys line includes manual motor starters with magnetic protection at 13 times the maximum dial setting, thermal overload relays with screw clamp terminal connections, and 3-pole contactors offering a lifetime of approximately one million electrical operations. These devices are designed to switch and protect common motor applications. The TeSys™ island Communicating Motor Starters eliminate control wiring and PLC IO with a single ribbon cable click, providing access to data via industrial communication protocols.

Siemens’ SINAMICS V20 Drives, with their compact, robust, and rugged design, are ideal for use in a variety of basic drive applications in process and manufacturing facilities. Moreover, the SIRIUS 3RA23 Series Reversing Contactor Assemblies prevent wiring errors in the main and control circuits. Controls SIRIUS Contactors offer flexible options for switching electrical loads, with conventional and solid-state operating mechanism choices.

Omron's MX2 Series Variable Frequency Drives offer advanced motor and machine control using VFD technology for precise operation, energy savings, and fault protection. With their advanced design and algorithms, the MX2 provides smooth control down to zero-speed and torque control capability in open loop.

Figure 4: Schneider Electric TeSys Thermal Overload Relay. (Image source: Schneider Electric)

Figure 4: Schneider Electric TeSys Thermal Overload Relay. (Image source: Schneider Electric)

Improving Sustainability in an Automated Production Line

To illustrate the impact of motion and control technologies on sustainability, let's consider an automated production line in a manufacturing plant. From precise control of conveyor speeds and packaging machine motors to the integration of robotic arms and the implementation of safety systems, these components enable manufacturers to achieve their goals of minimizing energy consumption and waste, while ensuring the safety and reliability of operations:

Conveyor Systems: In the automated production line, conveyor systems play a key role in transporting materials and products between different stages of the manufacturing process. By incorporating Schneider Electric's Altivar 212 VSD or Omron MX2 Series VFD, the speed of conveyor motors can be controlled to match the required production rate. By ensuring that the conveyor runs at optimal speed, energy consumption is lower, and there is less wear and tear on mechanical components. Additionally, soft starters like Schneider Electric’s Altivar™ Soft Starter ATS480 provide smooth start and stop of conveyor motors, reducing mechanical stress and extending the lifespan of the equipment.

Packaging Machines: Packaging machines are an integral part of the automated production line, responsible for wrapping, sealing, and labeling products. These machines often require precise control of motor speed and torque to ensure consistent and accurate packaging. By integrating Schneider Electric's ATV320 VFDs, packaging machine motors can be controlled with high precision, enhancing the system’s overall performance and energy efficiency.

Robotic Arms: Robotic arms are widely utilized in automated production lines for tasks such as material handling, assembly, and quality inspection. These tools require precise control of multiple axes of motion to perform their tasks accurately and efficiently. Schneider Electric's TeSys island Communicating Motor Starters offer control for robotic arm motors. By avoiding the need for complex wiring and PLC IO, the TeSys island also facilitates faster installation and easy configuration of the robotic arm’s control system. The built-in digital interface and smart configuration tool simplifies commissioning and adjustment, while the ability to access critical data via communication protocols allows for remote monitoring and predictive maintenance.

Pumps and Fans: Pumps and fans are vital in various aspects of an automated production line, such as cooling systems, hydraulic power units, and ventilation systems. Optimizing the performance of these components can lower the energy consumption and ensure maximum uptime. Siemens’ SINAMICS V20 Drives, with their compact, ruggedized design, are suitable for controlling pumps and fans in industrial environments. The SINAMICS V20 Drives offer various functions, including PID control, multi-pump control, and energy-saving modes.

Safety Systems: Ensuring the safety of personnel and equipment is of utmost importance in manufacturing facilities. With safety-rated contactor assemblies, production lines can achieve a high level of safety, reducing the risk of accidents and downtime. Siemens’ SIRIUS 3RA23 Series Reversing Contactor Assemblies can implement safety functions in the motor control system. These assemblies integrate seamlessly into functional safety systems according to international standards such as IEC 61508 and ISO 13849-1. The integrated mechanical and electrical interlocking features of the 3RA23 Series also avoid wiring errors and ensure safe operation of reversing motor circuits.

Figure 5: Smart industrial robot arms for digital factory production. (Image source: Shutterstock)

Figure 5: Smart industrial robot arms for digital factory production. (Image source: Shutterstock)

Conclusion

Advanced motion and control solutions are critical drivers of efficiency and sustainability in a wide range of industries. By integrating these technologies into automated production lines, manufacturers improve operational efficiency, reduce energy consumption, minimize material waste, and extend equipment lifetimes. DigiKey's portfolio of products sourced from multiple suppliers enables engineers and designers to create systems that deliver high performance while being eco-friendly. DigiKey provides a platform where engineers can explore, compare, and procure the most suitable motion and control products for their applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.