How to Optimize Intra Logistics to Streamline and Speed Industry 4.0 Supply Chains – Part One of Two

Contributed By DigiKey's North American Editors

2023-08-17

Intra logistics (internal logistics) uses autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) to efficiently move materials around Industry 4.0 warehouses and production facilities. In this article, the issues related to how AMRs and AGVs are used on a system level for implementing intra logistics and quickly and safely moving materials as needed are discussed. Part 2 of this series focuses on use cases and how AMRs and AGVs employ sensors to identify and track items, how ML and AI support material identification, movement and delivery of materials throughout warehouse and production facilities.

Moving materials rapidly from the receiving dock to the shipping dock in a warehouse or from location to location in a manufacturing facility — called intra logistics (for internal logistics) — is a critical aspect of streamlining and speeding up supply chain operations in Industry 4.0. There’s more to intra logistics than raw speed; it must be done efficiently, accurately, and with reduced waste for maximum benefits. Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) can be critical to improved intra logistics.

AMRs and AGVs look similar but operate differently. While traditional AGVs are preprogrammed to perform limited functions for the lowest costs, new models of AGVs are available with sensors like AMRs, blurring the distinction between the two. As a result of safety concerns, traditional AGVs operate in areas separate from people, but newer models include sensors for collision avoidance and can ensure higher levels of safety.

This article begins with a review of intra logistics and how it can be used to speed up supply chains. It then compares the operation and uses of AGVs and AMRs and briefly considers the differences between the two in terms of navigation and obstacle avoidance capabilities, flexibility, safety, deployment challenges, maintenance, and cost of ownership. At the same time, it looks at the blurring distinction between AMRs and AVGs and closes with a look at how the use of digital twins may enhance future intra logistics operations. The second article in this series will dive deeper into the wide range of sensor technologies AMRs and AGVs need. Digi-Key offers a full range of automation products for intra logistics in both cases.

Intra logistics defined

Intra logistics is deployed using cyber-physical systems designed to optimize internal distribution and production processes. To be fully effective, an intra logistics system must also be integrated with the larger supply chain through the Internet and local operational processes.

In warehouses, the system includes knowing where all the material is in the facility, what is needed to fulfill outstanding orders, what may be missing to complete orders, and where incoming material is in the broader supply chain.

In factories, intra logistics includes knowing what material is needed for specific manufacturing processes and supporting maximum scheduling efficiency by coordinating information about what’s currently in the facility and when additional materials will arrive, combined with machine and operator availability.

When fully integrated, information about material availability, people, their skills and locations, plus machinery and its availability, reduces costs by minimizing inventory, increasing flexibility for mass customization, and improving quality (Figure 1).

Figure 1: Intra logistics can integrate information about material, people, and machines to optimize Industry 4.0 operations. (Image source: Getty Images)

Figure 1: Intra logistics can integrate information about material, people, and machines to optimize Industry 4.0 operations. (Image source: Getty Images)

Intra logistics impacts process engineering, systems design, project management, material requirements planning, and numerous other functions. The automated movement of material throughout the facility is key to maximizing the benefits of intra logistics.

Material handling options

AMRs and AGVs are designed to move material from place to place, enhancing the efficiency, accuracy, productivity, and safety of intra logistics operations. These systems can be differentiated based on their load-carrying configurations. There are several configurations of AMRs and AGVs suited for specific intra logistics functions:

- Carts are also called under load or under ride vehicles and move beneath the item to be moved, lift it vertically, and carry it to its destination. These vehicles can be designed to lift and transport 1 ton or more.

- Tow tractors or tugs connect with one or more automated or unautomated carts loaded with material and take them from place to place. Most are rated for about 1 ton, but models are available rated for 20-ton loads. In addition, models are available that can operate autonomously or be manually driven by an operator.

- Robotic forklifts are available in several configurations, including pallet movers, counterbalanced fork trucks, and narrow aisle vehicles. Depending on the design, they can handle several tons and lift the load over 10 meters high.

- Load carriers are automated mobile platforms that can pick up materials from the end of a conveyor line, from robotic loading stations and other automated systems. Their load capacities tend to be lower than the other types of AMRs and AGVs.

AGV vs. AMR, what’s the difference?

AGVs and AMRs can have similar configurations, but they don’t have the same capabilities. The basic differences include:

- AGVs navigate using external tracks made with magnetic strips, tapes/paint on the floor, or wires in the floor to move from place to place; they cannot go anywhere without those external tracks.

- AMRs use a combination of internal sensors, wirelessly connected external sensors, artificial intelligence (AI), and machine learning (ML) to plan the most efficient route and avoid obstacles dynamically.

AGVs were developed before the introduction of Industry 4.0 warehouses and factories and have recently evolved somewhat to accommodate Industry 4.0 applications, so the differences are not as clear-cut as they once were. Similarities and differences include:

Navigation and obstacle avoidance. Navigation is the biggest differentiator. AGVs can only travel on predefined paths, while AMRs can travel variable routes throughout a predefined area or environment. Since they move autonomously, AMRs have extensive obstacle avoidance capabilities, including identifying new obstacles like a pallet placed in a previously clear aisle and sensing and avoiding personnel in their paths. Early models of AGVs had limited obstacle avoidance capabilities, and the areas where they were used were designed to be devoid of people. Newer AGVs include a larger variety of sensors, making them safer for use around people. However, while AVGs can identify obstacles, they can’t navigate around them like AMRs can. Instead, AVGs stop until the obstacle is removed. Some models can automatically resume their travel if an obstacle is moved out of the way.

Flexibility. AMRs can provide more flexibility and can be reprogrammed for deployment into new environments without physical modifications. When an AGV is introduced into a new environment, the guide tracks must be installed or modified to support the needed travel routes. AGVs are also limited to a single task involving the movement of material from one predetermined point to another and can be disrupted by changes in the environment, like the addition of new equipment that requires changes to the travel route.

Safety. Because of their greater ability to avoid obstacles, AMRs are generally considered safer than AGVs. But it’s not a simple question. Both can be equipped with emergency stop switches and sensors to identify obstacles and avoid hitting them — including people. AMRs are designed for use around people and include numerous safety measures. However, AGVs travel predetermined routes, and personnel know in advance where they will be and can more easily avoid contact with them. Both technologies support high levels of safety.

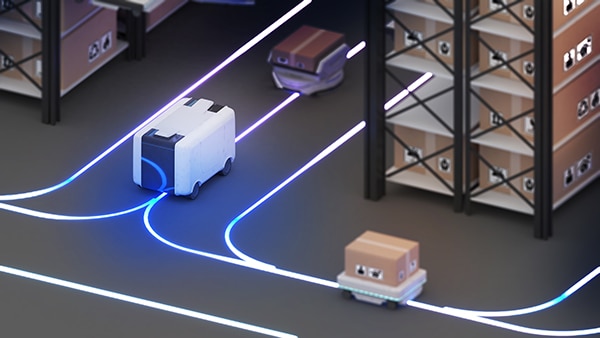

Deployment challenges. AGVs and AMRs require specific infrastructure to support their deployments. In general, AMR deployments can be completed faster and are less disruptive compared to AGVs. AGVs require the installation of guide tracks to support point-to-point navigation. AMRs depend on various sensors installed throughout the facility and help provide detailed situational awareness and navigation support. AMRs are suitable for use in more complex environments and applications. For example, an AMR can be programmed to work collaboratively with a human order picker in a “follow-me” application. Those differences generally make AMRs more suitable for use in Industry 4.0 environments where changes are expected and must be efficiently supported (Figure 2).

Figure 2: AGVs travel fixed routes making them less suitable for many Industry 4.0 applications. (Image source: Getty Images)

Figure 2: AGVs travel fixed routes making them less suitable for many Industry 4.0 applications. (Image source: Getty Images)

Maintenance. This is a mixed situation. AGVs are simpler machines with fewer sensors and can require less maintenance than AMRs. However, the support infrastructure needed by AGVs can be subject to damage requiring additional maintenance. In the case of AMRs, the suite of sensors can require maintenance, and software updates are periodically needed. The requirement that AGVs travel in areas separated from people often means that they travel longer distances to reach a destination compared with AMRs. Longer travel distances increase wear on AGVs, potentially increasing maintenance costs. So, the question of which needs more maintenance — AGVs or AMRs — is application dependent.

Cost. AGVs are simpler machines and cost less than AMRs. Installation cost differences are more complex to define since AGVs require the installation of guide tracks, while AMRs need a suite of external sensors and wireless connectivity. Operating costs are higher for AGVs since their guide tracks require more maintenance than the infrastructure needed to support AMRs. Finally, AMRs can usually be deployed faster, reducing the costs associated with downtime in the facility and making them more suitable for use in Industry 4.0 applications.

Digital twins, digital threads, and intra logistics

Digital twins and digital threads can be valuable tools for intra logistics deployments. Digital twins are detailed virtual models of complex cyber-physical systems like those used for intra logistics. Digital twins are created using data from various sources, including sensors in the facility, computer-aided design (CAD) models of the facility, feedback from sensors on equipment operating in the facility, and so on. They are used to provide real-time simulations of the warehouse or factory operation to help optimize processes and pinpoint potential problems before they arise (Figure 3). A digital thread accompanies the digital twin and includes the complete history of all activities in the digital twin throughout its operational lifetime.

Figure 3: A digital twin (left) can provide real-time simulations to support higher productivity in Industry 4.0 factories. (Image source: Getty Images)

Figure 3: A digital twin (left) can provide real-time simulations to support higher productivity in Industry 4.0 factories. (Image source: Getty Images)

Digital twins and digital threads in intra logistics are in the early stages of development. Predictable operations are important to efficient intra logistics systems. AMRs, AGVs, and robots operate with high levels of predictability and repeatability, and their use in Industry 4.0 can simplify the use of digital twin technology. Including them in the digital twin supports fleet optimization and management in the facility and enables preventative maintenance with minimal impact on operational efficiencies.

Digital twins are supported by large quantities of real-time data, including environmental conditions as well as functional and operational data about the state of machines and processes. The digital twin uses that data to simulate the actual systems and predict the condition of complete machines and individual components like the battery packs in AGVs and AMRs to optimize their performance.

The closer the digital twin simulates the real world, the greater the benefits. An infra logistics system typically integrates automated systems with people. Including human activities in the digital twin can further enhance the accuracy of the simulations and the benefits of intra logistics. The combination of intra logistics, digital twins, and digital threads with artificial intelligence and machine learning are expected to be important elements supporting the emergence of fully automated Industry 4.0 factories and warehouses.

Summary

Intra logistics is the movement of materials within an industrial facility like a warehouse or factory. AGVs and AMRs are important tools used to automate and speed the flow of materials. While both have advantages and disadvantages, AMRs are more suited for use in Industry 4.0 applications. When combined with digital twins, AI, and ML, intra logistics can support the development of fully automated factories and warehouses.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.