How to Deploy Wireless LED Lighting Controls in Smart Cities and Industrial Buildings

Contributed By DigiKey's North American Editors

2022-11-11

The use of LED lighting systems with wireless controls in smart city and Industry 4.0 settings is growing because it brings multiple benefits, including lower energy costs (and a corresponding reduction in carbon emissions), controllable lighting levels, and reduced maintenance costs from the higher reliability and longer operating lives of LED luminaires. To be most effective, these LED lighting systems need a lighting controller with various operating modes, sensing and protection features, plus high efficiency and a wide operating voltage range from 90 to 300 volts alternating current (VAC), along with high power factor (PF) and low total harmonic distortion (THD). In addition, a microcontroller (MCU), data concentrator, and wireless transceiver are needed to complete the system. Designing a wireless LED lighting control system from scratch is a multi-disciplinary task that carries a significant risk level and can delay market time.

Instead, designers can use pre-engineered connected LED lighting control development platforms. These platforms are highly energy efficient, with high PF, and feature comprehensive wireless controls (on/off, dimming, and other modes) and multiple independently controlled LED channels that provide maximum design flexibility. They include wireless communications modules that support protocols such as Bluetooth low energy (BLE), Zigbee, and 6LoWPAN. Additionally, they are supported by development environments that include customizable firmware, Free RTOS, and various use cases.

This article begins by reviewing basic LED operation and luminaire construction plus metrics for measuring the efficiency of LEDs and luminaires. It discusses the use of shunts to maximize luminaire reliability and performance in smart city and Industry 4.0 applications. It then presents pre-engineered connected LED lighting drive and control development platforms, and related components, from STMicroelectronics and onsemi, along with design and deployment considerations.

Smart LED lighting control begins with controlling the interaction between LEDs in each string to optimize luminaire performance. It also includes smart power conversion and extends to wireless control of multiple luminaires, including both hardware and software, to maximize the performance of street lighting and industrial lighting networks.

A typical LED luminaire includes multiple LEDs in series in one or more strings. Each LED requires a drive voltage of about 3.5 V. A string usually contains from 10 to 30 LEDs and operates from a supply of 40 to 100 V, drawing from about 0.35 to 1.0 amperes (A) of current, depending on the brightness of the individual LEDs (Figure 1).

Figure 1: Two strings of 16 LEDs each for use in smart luminaries. (Image source: onsemi)

Figure 1: Two strings of 16 LEDs each for use in smart luminaries. (Image source: onsemi)

The brightness of light sources is quantified in lumens (lm) that measure the apparent brightness to the human eye and account for the eye's sensitivity to various wavelengths of visible light. The efficiency with which a light source produces lumens is called the efficacy and is measured in lumens per watt (lm/W). LEDs have higher efficacy than other common lighting technologies. However, not all LEDs are equally efficient, and some have significantly higher efficacies than others. Furthermore, a given LED can produce more light if driven with more current.

LEDs are more reliable than other lighting technologies, but they're not perfect. LEDs can fail, especially if they are driven hard in a high-performance luminaire such as those used in streetlighting and industrial lighting. LED failure can be a short or an open circuit. If an LED in a string fails in a short circuit condition, it goes dark, but the remaining LEDs in the string continue to operate. Current continues flowing through the shorted LED, heating it to the point that it can become an open circuit, causing the entire string to go dark.

Shunting LEDs

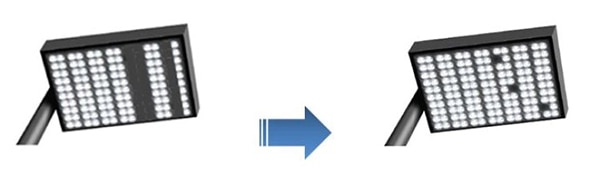

LED luminaire designers are challenged to deliver more lumens in smaller luminaires. That often requires that the LEDs operate at higher temperatures for extended periods and can result in LED failures. Streetlight luminaires, in particular, are expected to have operating lifetimes of up to 15 years. Bypass shunts can help reconcile the conflicting demands for higher operating temperatures and extended lifetimes. When an LED fails in the open state, instead of the string going dark, the shunt bypasses the LED and keeps the string operating normally with only the failed LED going dark (Figure 2).

Figure 2: Without bypass shunts, a single LED failure results in the loss of the entire string (left). With bypass shunts, only the failed LED goes dark, and the remaining LEDs in the string continue to operate (right). (Image source: onsemi)

Figure 2: Without bypass shunts, a single LED failure results in the loss of the entire string (left). With bypass shunts, only the failed LED goes dark, and the remaining LEDs in the string continue to operate (right). (Image source: onsemi)

Shunts are available that can be used to bypass one or two LEDs, depending on the needs of the luminaire design (Figure 3). Bypassing each LED supports a minimal drop in brightness if an LED fails, while bypassing two LEDs reduces the number of shunts in half for more cost-sensitive solutions. For example, the NUD4700SNT1G from onsemi can be used to bypass individual LEDs in a string, and it automatically resets if the LED resumes operation or is replaced. The LBP01-0810B from STMicroelectronics can bypass either 1 or 2 LEDs, increasing design flexibility and reducing part numbers. The LBP01-0810B also provides overvoltage protection against surges defined in IEC 61000-4-2 and IEC 61000-4-5.

Figure 3: LED shunts (inside the dotted boxes) are available that can bypass 1 (left) or 2 (right) LEDs. (Image source: onsemi)

Figure 3: LED shunts (inside the dotted boxes) are available that can bypass 1 (left) or 2 (right) LEDs. (Image source: onsemi)

Smart street lighting

Designers of smart street lighting systems can turn to the STEVAL-LLL006V1 board from STMicroelectronics to evaluate options for high-power LED lighting (Figure 4). The integrated HVLED001A LED lighting controller includes various operating modes, sensing and protection mechanisms, and produces an intelligent and efficient power converter using STP21N90K5 MOSFETs. This LED driver board uses the VIPER012LSTR off-line high-voltage converter IC to provide an output of 60 to 110 V direct current (dc) with a constant current of 0.7 A. To meet the needs of smart street lighting applications, the driver has a 90 to 300 VAC input range, a PF over 0.97, and THD under 15%. The embedded SPSGRFC sub-1 GigaHertz (GHz) transceiver module can be used to receive on, off, and dimming commands and send them to the integrated STM32L071KZ microcontroller. It supports five levels of analog dimming.

Figure 4: The STEVAL-LLL006V1 LED lighting dev board is part of a platform that includes power management and wireless connectivity. (Image source: STMicroelectronics)

Figure 4: The STEVAL-LLL006V1 LED lighting dev board is part of a platform that includes power management and wireless connectivity. (Image source: STMicroelectronics)

Development tools

To speed the development process and highlight the functionality of the STEVAL-LLL006V1 eval board, a data concentrator unit (DCU) and Android mobile application are available. The DCU is an integrated eval environment built on the NUCLEO-F401RE platform. It includes a X-NUCLEO-IDS01A4 board for sub-1-GHz communication with the STEVAL-LLL006V1 and a X-NUCLEO-IDB05A2 board for Bluetooth communication with a mobile device. STMicroelectronics also offers their 6LoWPAN Smart Streetlight mobile application that can be used to form a mesh of smart street lighting controllers and evaluate network functionality.

Industrial LED lighting

Connected industrial LED lighting solutions can be prototyped using the LIGHTING-1-GEVK Connected Lighting Platform from onsemi. This dev platform features wireless control, the choice of using an off-line ac/dc power supply or an optional power over Ethernet (PoE) power source, an LED module, and an LED driver module, plus a BLE connectivity module to tie everything together. Available control options include using onsemi's RSL10 Sense and Control mobile app or a web client. This dev platform includes Free RTOS, a CMSIS-Pack with customizable firmware, and several use cases to start exploring the use of connected industrial LED lighting solutions.

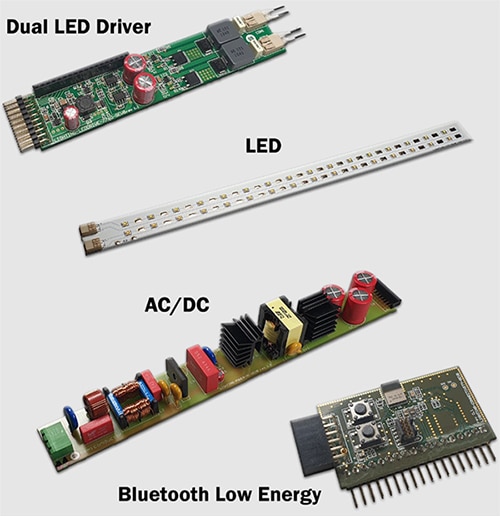

The basic LIGHTING-1-GEVK kit includes a dual LED driver, LED board with two LED strings, an ac/dc power supply, and a BLE communications module (Figure 5). A PoE power module is available separately that can deliver up to 90 W. Some key specifications of the various boards in the kit include:

- Dual LED driver: includes two FL7760 LED drivers that deliver up to 25 W each with up to up to 96% efficiency, 4,000 step dimming down to 0.6%, telemetry data including current and voltage measurements for each LED driver, and a header for the pluggable MCU module to support wireless connectivity.

- LED board: dual independent channels with 16 LEDs in each channel. One channel has LEDs rated for 121 lm, and the other channel has LEDs rated for 95 lm, for a total available brightness of 7,000 lm.

- AC/DC power supply: includes two FL7740 primary side regulation flyback controllers with PFC, operates over an input range of 90 to 270 VAC, produces an output of 70 W at 55 V to power the LED driver board, with a PF over 0.99 and efficiency over 91%.

- BLE module: The connected lighting platform uses three BLE services; lighting control service used by connected devices to remotely read and change the state of the LEDs, telemetry service used by connected devices to monitor the voltage and current in the LED drivers, and the PoE power delivery service providing information about PoE power limits imposed on the device by the PoE power injector.

Figure 5: The basic dev kit includes a dual LED driver, dual LED string, ac/dc power supply, and a BLE connectivity module. (Image source: onsemi)

Figure 5: The basic dev kit includes a dual LED driver, dual LED string, ac/dc power supply, and a BLE connectivity module. (Image source: onsemi)

Expansion boards

Two expansion boards are available for the LIGHTING-1-GEVK kit, the BLE-SWITCH001-GEVB energy harvesting BLE switch, and the MULTI-SENSE-GEVB multi-sensor board (Figure 6). LED brightness can be controlled with the BLE switch. Brightness increases when the switch is pressed and held down. Light intensity remains constant when the switch is released or when maximum brightness is reached. Brightness is decreased by pressing the switch a second time. The multi-sensor board supports prototyping of systems that include an ambient light sensor, environmental sensors, and/or an inertial motion sensor.

Figure 6: Two expansion boards are available for the LIGHTING-1-GEVK kit, a BLE switch, and a multi-sensor board (top green box). (Image source: onsemi)

Figure 6: Two expansion boards are available for the LIGHTING-1-GEVK kit, a BLE switch, and a multi-sensor board (top green box). (Image source: onsemi)

Design and deployment options

LED streetlights and industrial luminaires bring new opportunities to rethink the design and deployment of lighting networks. Unlike the technologies they usually replace, LEDs are dimmable, which creates opportunities to design smart cities and smart industry 4.0 facilities that integrate various factors such as traffic/usage patterns, time of day, and even a suite of sensors to optimize lighting levels as needed.

In a smart city, wireless mesh networks are a natural choice, but in Industry 4.0 facilities, control can be implemented with wireless or Ethernet connectivity. Ethernet has the benefit of delivering power as well as communications. In either case, temperature, humidity, and even camera sensors can be integrated into the luminaires, increasing their functionality. Additionally, the operating conditions of the luminaires themselves, such as internal temperatures, shorted or open LEDs, and other factors, can be monitored to help schedule preventative maintenance and reduce operating costs.

Summary

As shown, designing a reliable and efficient connected LED lighting system begins with the design of the luminaires. The LEDs need to be selected to provide the optimal level of lumens, and the use of shunts can significantly improve luminaire reliability and performance. The use of wired or wireless connected LED lighting in smart cities, and industry 4.0 facilities can reduce ongoing maintenance and operational costs in addition to reducing energy consumption. Comprehensive development platforms are available to help speed the design and deployment of smart connected LED lighting solutions.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.