How to Cost-Effectively Implement Reliable Aircraft Navigation Systems With Precision Components

Contributed By DigiKey's North American Editors

2024-04-11

Developing sophisticated air data, attitude, and heading reference system (ADAHRS) solutions is crucial to ensure accurate navigation and safety in manned and unmanned aircraft systems. To create robust, reliable ADAHRS designs, developers need components that can address multiple challenges in avionics navigation systems design, including sensor accuracy, environmental resilience, and system integration.

This article describes how precision data acquisition modules and inertial measurement units (IMUs) from Analog Devices address these challenges and simplify the development of effective ADAHRS solutions.

Aviation safety builds on sophisticated sensor-based systems

The availability of accurate flight performance information is critical to safety in all aviation segments, ranging from unmanned aerial systems (UASs) to heavy passenger jets. Matching aerodynamic improvements in aircraft, avionics systems’ capabilities have evolved from the pilot’s traditional “six-pack” of flight instruments based on magnetic compasses, mechanical gyroscopes, and vacuum-driven flight instruments, to increasingly sophisticated graphical display electronic flight instrument system (EFIS) “glass cockpits.”

Underlying the EFIS, the ADAHRS integrates the capabilities of an air data computer and an attitude and heading reference system (AHRS) required to complement long-range global navigation satellite system (GNSS) navigation aids, such as the U.S. global positioning system (GPS) and the GPS’s associated ground-based wide area augmentation system (WAAS). The air data computer calculates altitude and vertical, air, and ground speed using atmospheric pressure measurements and outside air temperature. To provide the aircraft attitude (pitch, roll, and yaw) and heading data needed for dead reckoning in inertial navigation, the ADAHRS relies on a combination of gyroscopes for changes in angular velocity, accelerometers for changes in linear velocity, and magnetometers for magnetic heading. Advances in sensor technology have dramatically changed the nature of these critical sensors.

In the past, complex fiber optic or ring laser gyroscopes were among the few available technologies that could deliver sufficient accuracy for aviation. Today, the availability of advanced microelectromechanical systems (MEMS) provides developers with a technology that can satisfy requirements across diverse aviation platforms (Figure 1).

Figure 1: High-end MEMS gyroscopes offer unique characteristics that make them the preferred technology for electronic avionics systems. (Image source: Analog Devices)

Figure 1: High-end MEMS gyroscopes offer unique characteristics that make them the preferred technology for electronic avionics systems. (Image source: Analog Devices)

Along with gyroscopes, accelerometers, and magnetometers, ADAHRS functionality also depends on reliable data streams from sensors reporting outside air temperature and pressure. Other pressure, force, and position sensors deliver data on the position and loading of flight surfaces, landing gear, and nosewheel steering. Additional sensors provide essential data on engine performance and fuel needed for engine information systems, as well as cabin temperature, pressure, and oxygen levels.

A combination of high-performance sensor data acquisition modules and MEMS IMUs from Analog Devices provides developers with the critical components required to deliver avionics solutions with reliability, accuracy, size, and cost characteristics that permit their application across the full range of aviation flight systems.

Applying sensor data acquisition modules and IMUs in modern avionics

For acquiring data from the broad array of sensors in any flight platform, high-performance data acquisition modules offer a range of performance capabilities for each sensor modality and functional requirement. With its Precision Signal Chain µModule Solutions, Analog Devices integrates common signal processing subsystems including signal conditioning blocks and analog-to-digital converters (ADCs) in a compact system-in-package (SIP) device to solve tough design challenges. The μModules also incorporate the critical passive components with superior matching and drift characteristics built using Analog Devices iPassive® technology, which minimize temperature dependent error sources and simplify calibration while mitigating thermal challenges. Significant solution footprint reduction enables addition of more channels/functions for scalable aviation instruments requiring precision and stability over temperature and time. The µModules simplifies signal chain Bill of Material (BOM), reduces performance sensitivity to external circuitry, shortens design cycles, therefore reducing the total cost of ownership.

Designed to meet the demanding data acquisition requirements, Analog Devices’ ADAQ4003 and ADAQ23878 μModules integrate a fully differential ADC driver amplifier (FDA, Figure 2) with a 0.005% precision matched resistor array, a stable reference buffer, and an 18-bit successive approximation register (SAR) ADC, capable of delivering 2 megasamples per second (MSPS) and 15 MSPS performance, respectively.

By combining a μModule data acquisition device like the ADAQ4003 with a fully differential programmable-gain instrumentation amplifier (PGIA), such as Analog Devices’ LTC6373, developers can implement a simple solution to many of the complex sensing requirements of aviation systems.

Figure 2: Developers can efficiently meet many aviation sensing requirements by combining an LTC6373 fully differential PGIA with an ADAQ4003 μModule data acquisition system. (Image source: Analog Devices)

Figure 2: Developers can efficiently meet many aviation sensing requirements by combining an LTC6373 fully differential PGIA with an ADAQ4003 μModule data acquisition system. (Image source: Analog Devices)

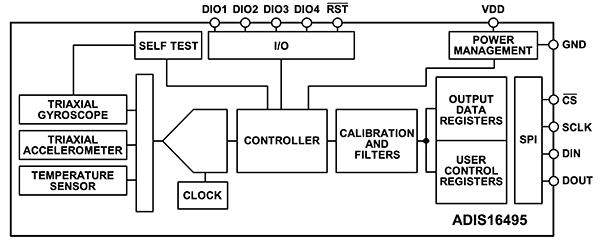

As noted earlier, MEMS-based sensors offer an effective solution for delivering the critical data required for ADAHRS functionality. By integrating MEMS triaxial gyroscopes and triaxial accelerometers with temperature sensors and other functional blocks, IMUs with six degrees of freedom, such as Analog Devices’ ADIS16505 precision miniature MEMS IMU and ADIS16495 tactical-grade inertial sensor, provide the complete set of functionality required to simplify development of avionics subsystems (Figure 3).

Figure 3: The ADIS16505 IMU and ADIS16495 IMU (shown here) integrate sensors with a controller, calibration, signal processing, and self-test blocks to provide a complete solution for electronic measurement systems’ underlying avionics systems like ADAHRS. (Image source: Analog Devices)

Figure 3: The ADIS16505 IMU and ADIS16495 IMU (shown here) integrate sensors with a controller, calibration, signal processing, and self-test blocks to provide a complete solution for electronic measurement systems’ underlying avionics systems like ADAHRS. (Image source: Analog Devices)

Combined in the ADAHRS, these systems can provide the essential components of inertial navigation systems able to provide the required heading to the desired destination even without satellite or ground-based navigation aids. As with any manufactured device, MEMS-based devices are subject to different sources of performance limitations that can degrade the accuracy of computed navigation. For example, inevitable variations in manufacturing, internal noise sources, and environmental effects limit a MEMS gyroscope’s accuracy.

Manufacturers document the performance effects of these variations in numerous datasheet parameter specifications. Among these specifications, sensitivity, nonlinearity, and bias parameters can directly impact ADAHRS accuracy. In gyroscopes, limited sensitivity (angular rate measurement resolution) can result in heading error (Ψ) and position error (de) during turns (Figure 4, left); nonlinear response (deviation from ideal linear response) can result in similar errors following a series of maneuvers such as S-turns (Figure 4, middle); and gyroscope bias results in a drift in heading and position even during cruise (straight and level flight with no acceleration) (Figure 4, right).

Figure 4: Gyroscope sensitivity limitations, nonlinearity, and bias can result in the accumulation of heading error (Ψ) and position error (de) during turns (left), S-turns (middle), and cruise (right). (Image source: Analog Devices)

Figure 4: Gyroscope sensitivity limitations, nonlinearity, and bias can result in the accumulation of heading error (Ψ) and position error (de) during turns (left), S-turns (middle), and cruise (right). (Image source: Analog Devices)

Bias errors arise from the misalignment of each gyroscope axis to other axes or the package, scaling errors, and the gyroscope’s incorrect response to linear acceleration as rotation due to asymmetries in the MEMS fabrication. For its ADIS16505 and ADIS16495 IMUs, Analog Devices determines bias correction factors specific to each device by testing them at multiple rotation rates and temperatures. These part-specific bias correction factors are stored in each part’s internal flash memory and applied during sensor signal processing.

In addition to the correctable bias factors, random noise from various sources impacts bias error over time. Although it is not possible to compensate for this random noise directly, its effects can be reduced by sampling over longer integration times. The degree to which longer sampling times will reduce noise is described in a gyroscope datasheet’s Allan deviation (or Allan variance) plot, which displays noise in degrees per hour (°/hr) versus the integration period (τ) (Figure 5).

Figure 5: Allan deviation plots for the MEMS gyroscopes in the ADIS16495 IMU (left) and ADIS16505 IMU (right) describe the ability of extended sampling time to compensate for random drift. (Image source: Analog Devices)

Figure 5: Allan deviation plots for the MEMS gyroscopes in the ADIS16495 IMU (left) and ADIS16505 IMU (right) describe the ability of extended sampling time to compensate for random drift. (Image source: Analog Devices)

The minimum of the Allan deviation plot represents the best case for the gyroscope’s drift over time, a parameter called in-run bias stability (IRBS) typically specified in terms of the sum of the mean and one standard deviation in datasheet specifications. For developers creating highly accurate ADAHRS solutions, an IMU’s IRBS provides an essential parameter for understanding the best-case performance possible with that part. Gyroscope experts classify IMUs such as Analog Devices’ ADIS16495 as “tactical grade” when their gyroscope’s IRBS values are between 0.5° and 5.0°/hr.

The ADIS16495 features tight specifications across multiple vital parameters to meet more demanding tactical applications. Aiding its enhanced performance, the ADIS16495 integrates a pair of MEMS gyroscopes and a dedicated 4100 hertz (Hz) sampling signal chain for each of its three axes (Figure 6).

Figure 6: The ADIS16495 tactical grade IMU improves gyroscope accuracy and drift performance by averaging the output from a pair of MEMS gyroscopes with dedicated signal chains. (Image source: Analog Devices)

Figure 6: The ADIS16495 tactical grade IMU improves gyroscope accuracy and drift performance by averaging the output from a pair of MEMS gyroscopes with dedicated signal chains. (Image source: Analog Devices)

Samples from each signal chain are then combined using a separate 4250 Hz sample frequency (fSM) to provide an angular rate measurement that reduces the effect of noise. Combining this sampling method with more stringent performance specifications results in an IMU capable of meeting more demanding avionics requirements.

Rapid development and exploration of IMU-based designs

To help speed the development of designs based on its IMUs, Analog Devices provides a comprehensive set of development tools. Designed to support its EVAL-ADIS-FX3 IMU evaluation board (Figure 7) and associated breakout boards, Analog Devices’ FX3 software stack comprises a firmware package, a .NET-compatible application programming interface (API), and a graphical user interface (GUI). A wrapper library provided with the API allows developers to work with any development environment that supports .NET, including those for MATLAB, LabView, and Python. During development, the FX3 evaluation GUI enables developers to easily read and write registers, capture data, and plot the results in real time.

Figure 7: The EVAL-ADIS-FX3 evaluation board is part of a comprehensive hardware and software support package to help exercise Analog Devices’ IMUs. (Image source: Analog Devices)

Figure 7: The EVAL-ADIS-FX3 evaluation board is part of a comprehensive hardware and software support package to help exercise Analog Devices’ IMUs. (Image source: Analog Devices)

Conclusion

ADAHRS avionics solutions form the heart of the evolving EFISs. With the development of precision gyroscopes, accelerometers, and magnetometers based on MEMS technologies, avionics systems can offer flight performance and navigation capabilities that have been beyond the reach of all but the largest fleets of commercial aircraft. Using data acquisition modules and highly integrated IMUs from Analog Devices, avionics developers can design more cost-effective, smaller solutions to meet the stringent requirements for functionality, safety, and reliability in aviation systems.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.