How to Combine LEDs, E-paper, and Gesture Recognition for Low-Power HMIs in Enterprise Connectivity

Contributed By DigiKey's North American Editors

2023-03-30

Human machine interfaces (HMIs) are an important element supporting enterprise connectivity for the Industrial Internet of Things (IIoT) in Industry 4.0 automation and process control, and automotive and medical systems. HMIs range from augmented reality goggles to touch screens and simple visual indicators. While augmented reality goggles get a lot of headlines and touch screens bring a lot of capabilities, simple, low-cost, miniature, and low-power visual indicators and controls are needed for a growing range of edge devices.

Designers can combine LED dot matrix or electronic paper (e-paper) displays (EPDs) with gesture recognition and proximity sensing infrared (IR) light angle sensor controls to implement low power, low cost, and feature-rich HMIs on IIoT edge nodes in Industry 4.0 and across a range of enterprise, medical, and automotive applications.

This article begins by reviewing the operation and capabilities of alphanumeric and dot matrix LED displays and EPDs, then details the use of IR light angle sensor ICs in gesture recognition and proximity sensing. It then presents representative LED displays from Broadcom and Lumex, an EPD from E Ink, an EPD development platform from Pervasive Displays, and an IR sensing IC for gesture recognition from Analog Devices, along with development platforms to speed the design and integration process for high performance, low power, miniature HMIs.

Alphanumeric LEDs

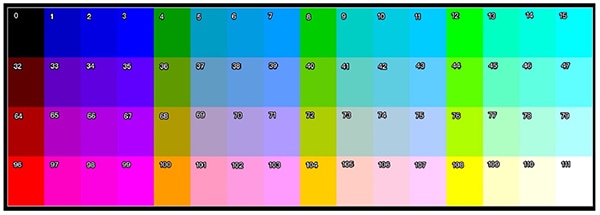

Alphanumeric LED displays are available that accept parallel and serial data inputs and a range of character numbers, sizes, and display widths. Each character is formed from a 5 x 7-pixel array—usually using a single LED color like red or green. These displays integrate character sets like the American Standard Code for Information Interchange (ASCII) characters, the ISO 15924 Japanese Katakana script character set that can be encoded in the ASCII character set, as well as country-specific characters and custom user-defined characters for special use cases (Figure 1). They can be daylight readable and environmentally rugged.

Figure 1: The ASCII character set as formed using a 5 x 7 pixel alphanumeric LED display. (Image source: Broadcom)

Figure 1: The ASCII character set as formed using a 5 x 7 pixel alphanumeric LED display. (Image source: Broadcom)

Visual LED displays

Instead of being used to form individual characters, LED dot matrix displays use LEDs arranged in a matrix layout to deliver graphics. They can also display standard ASCII, Katakana, and other text formats. In terms of performance, they are between the dot matrix displays described above and video LED displays. They are available in a wide range of sizes and can be single-color displays like red, green, or red green blue (RGB) multi-color displays. However, they usually have a more limited color palette and slower refresh rates compared with video displays (Figure 2). The LEDs are usually arranged in a grid pattern with either the negative or positive terminals of the LEDs tied together as a common circuit node. Visual LED displays are available that operate with I2C, 8-bit parallel, series, and other interfaces. Some include an onboard microcontroller unit (MCU), and others use the system processor.

Figure 2: Example of a color palette for an RGB LED display. (Image source: Lumex)

Figure 2: Example of a color palette for an RGB LED display. (Image source: Lumex)

What’s e-paper, and how does it work?

While LEDs require a continuous drive current to stay on, e-paper is a bistable technology that does not require continuous drive and can be extremely low power. When low power is a priority, refresh rates are low, and full color is not needed, e-paper displays (EPDs) can provide a viable alternative to LED and liquid crystal displays (LCDs). It takes very little power to render an image on an EPD; once the image is rendered, no power is needed to maintain it. EPDs have contrast like ink and paper. While most are black and white, some add another color, like red.

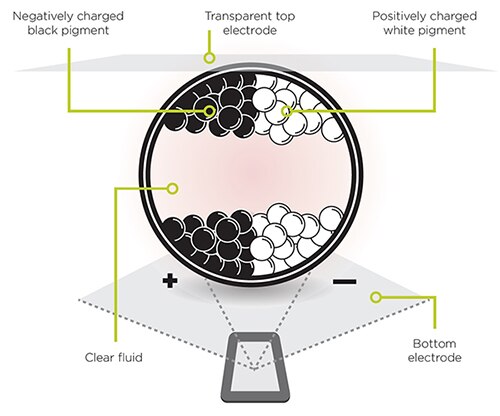

EPDs combine thin film transistor (TFT) technology with a layer of electronic ink. The ink comprises millions of tiny capsules containing electrically charged pigment particles. The ink is between two electrodes (Figure 3). Applying the needed drive to the TFT matrix causes the pigment particles to form a detailed image. Once the pigment particles have been moved into place, they remain there with no power applied. Driving EPDs can be a little tricky. The front panel laminate (FPL) varies slightly from batch to batch, requiring that the drive waveform be manually tuned. In addition, different drive waveforms can be required under different operating temperatures.

Figure 3: E-ink comprises millions of tiny capsules containing electrically charged pigment particles placed between two electrodes. (Image source: Pervasive Displays)

Figure 3: E-ink comprises millions of tiny capsules containing electrically charged pigment particles placed between two electrodes. (Image source: Pervasive Displays)

Gesture recognition

LEDs and EPDs can provide information to system users and operators. That’s only half of a complete HMI installation. Users and operators also need the ability to provide inputs and control signals to the system. In some applications, proximity sensing alerts the system to the presence of an operator, and the display automatically turns on to provide status information. While that’s useful for sending status information, it does not provide a mechanism for sending inputs and commands to the equipment. Using traditional keyboards, switches, and other mechanisms can be an option but can result in relatively large and power-hungry solutions. Instead, designers can turn to gesture recognition interfaces for proximity sensors to detect and translate hand movements and patterns into commands. Gesture recognition can be especially useful for noisy environments, where the background noise and ambient sounds make it difficult to use voice recognition. It takes three activities to implement basic gesture recognition:

- Recognizing the beginning and end of a gesture

- Tracking hand movement throughout the gesture

- Using the information from the first two steps to understand the gesture

Gesture recognition development platform

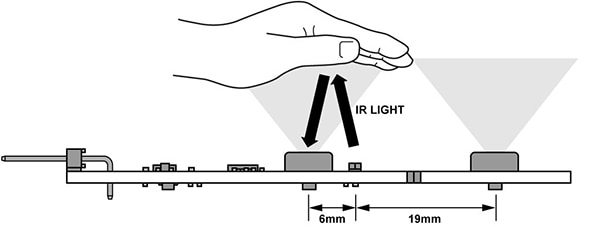

To develop a gesture recognition system, designers can turn to Analog Devices’ EVAL-CN0569-PMDZ reference design based on the ADPD2140 IR light angle sensor. The circuit emits an IR pulse train, and the sensor captures the reflected light. The design supports gesture sensing up to about 20 centimeters (cm) away from the board. The sample rate of up to 512 samples per second enables designers to adjust the noise rejection and response time to best suit the application and environment. Also noteworthy is that the ADPD2140 does not require precise alignment; its sensor has a linear response within a ±35° angular field of view (Figure 4). The integrated optical filter in the ADPD2140 package provides a sharp cutoff of visible light, further simplifying system design by eliminating the need for external lenses or filters while maintaining the dynamic range of the sensor under bright indoor lighting or sunlight.

Figure 4: The ADPD2140 IR light angle sensor has a linear response within a ±35° angular field of view. (Image source: Analog Devices)

Figure 4: The ADPD2140 IR light angle sensor has a linear response within a ±35° angular field of view. (Image source: Analog Devices)

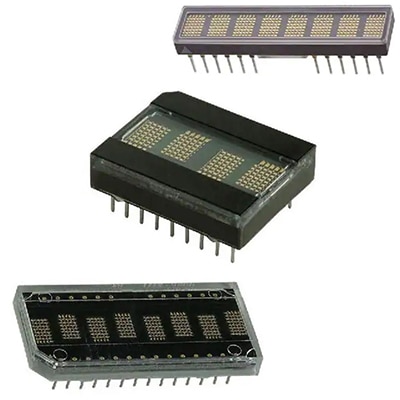

Alphanumeric LED displays

Applications that need bright and rugged alphanumeric LED displays can turn to designs with parallel interfaces or serial interfaces from Broadcom. The displays with parallel interfaces are available with 4 or 8 characters (Figure 5). They are available in several package styles, colors, and sizes, such as the 8-character, 5-millimeter (mm) HDSP-2533 with green LEDs and the 4-character, 3.7 mm HDLU-1414 with high-efficiency red LEDs, both in plastic packages. Or the 8-character, 5 mm, HDSP-2131 with yellow LEDs in a rugged glass/ceramic package. All include an integrated ASIC driver simplifying the design effort. Features of these parallel interface displays include:

- Seven to eight bus lines for data

- Character map with 128 ASCII and sixteen user-definable characters stored in programmable ROM

- Individual character flashing and blinking of all characters

- Scrolling function

- Eight brightness levels

- Stackable in x- and y-direction for larger display needs

Figure 5: Alphanumeric LED displays with parallel interfaces are available with 4 or 8 characters. (Image source: DigiKey)

Figure 5: Alphanumeric LED displays with parallel interfaces are available with 4 or 8 characters. (Image source: DigiKey)

Broadcom offers serial interface LED alphanumeric displays with 4, 8, and 16 characters like the 8-character, 5-mm green HCMS-3977 and the 8-character, 3.8 mm red HCMS-2912, both in plastic packages and the 4-character, 0.2 inch yellow-green HCMS-2333 in an extended temperature range glass/ceramic package. Features of these serial LED displays include:

- 128 ASCII, ISO 15924 Japanese Katakana script, and custom fonts

- Serial interface that supports high character count displays with minimal data lines

- Can interface directly with an MCU to simplify system design

- Sleep mode when the equipment is on standby

- 64 brightness levels

- Stackable in x- and y-directions supporting high character-count displays

LED dot matrix display

When the application requires a visual LED display for more complex information, designers can use the LDM-6432-P3-UR-1 from Lumex Opto. This 64 x 32-pixel RGB display has a 3 mm LED pitch (Figure 6). This display includes a UART interface, USB power socket plus 1.5 A current protector, and BLE 4.0 module. Developers can use a personal computer to develop the display software. Features include:

- Can handle HEX or Arduino AT commands

- Built-in fonts and basic shapes

- Can run in mixed character and graphic modes

- Multiple display modules can be stacked for larger displays

- Can be integrated with any MCU

- No driver or library needed

- Can display animation

- Different languages are available on request

Figure 6: This 64 x 32-pixel RGB LED display can be used to present more complex information. (Image source: Lumex Opto)

Figure 6: This 64 x 32-pixel RGB LED display can be used to present more complex information. (Image source: Lumex Opto)

e-paper display and dev board

Applications that benefit from an EPD can turn to the ED078KC2 from E Ink. It’s a reflective electrophoretic EPD module on an active matrix TFT substrate. It has 1404 x 1872 pixels in an active area of 7.8”. Depending on the controller, this EPD can display up to 16 levels of grey (Figure 7).

Pervasive Displays offers the B3000MS044, ext3, and the B3000MS037, ext3 giant, EPD extension boards to integrate this EPD into systems. The basic ext3 kit can drive 1.54” to 12” EPDs. For large EPDs, from 9.7” and 12”, the ext3 giant is also needed. This dev platform has an onboard driving circuit to simplify the development of EPD applications. In addition, Pervasive Displays offers expansion options, several open source driving codes, design resources, and development libraries for graphic and interactive capabilities.

Figure 7: This bistable EPD has 1404 x 1872 pixels in an active area of 7.8” and features very low power consumption. (Image source: DigiKey)

Figure 7: This bistable EPD has 1404 x 1872 pixels in an active area of 7.8” and features very low power consumption. (Image source: DigiKey)

Summary

IIoT edge devices that require an HMI can benefit from a range of compact and low-power technologies. Gesture recognition provides a way to provide commands and controls even in challenging environments. Alphanumeric LED displays are rugged, can be seen in high-light environments, and can be stacked to support larger information needs. LED dot matrix displays and EPDs can present more complex information. LED dot matrices can present RGB color displays and animations, while EPDs can be used for high-contrast greyscale displays that require very little power.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.