How to Achieve Precise and Reliable Control of Heavy Industrial Equipment in Rugged Environments

Contributed By DigiKey's North American Editors

2023-07-21

Designers of heavy construction, industrial, robotic, marine, and aeronautic equipment are adding greater functionality, while at the same time looking for ways to implement ever more precise control of delicate operations and movements using light, compact control systems. These goals must also be accomplished in a rugged and unforgiving environment that is both physically and electrically challenging.

To meet these demands, designers need to ensure the user interface has the level of precision, directional flexibility, and tactile feedback required for accurate control, while at the same time being robust and reliable over temperature extremes and usage cycles.

While touchscreens have their place, they lack the necessary tactile feedback and ruggedness. Also, classic X/Y joysticks tend to be both too bulky and lacking in the number of signaling options and axis needed for maximum directional control. Instead, designers can use low-profile joysticks, or thumbsticks, that are now capable of providing more refined control in a robust form factor. Operated by the user’s thumb or fingers, these small devices offer easy access to multiple inputs, even in cramped settings.

This article briefly discusses why modern industrial and other heavy equipment requires higher precision controls, and how low-profile thumbsticks address the relevant issues. It then reviews key design and implementation criteria, including sensor selection, ruggedization, and physical and electrical design options. Real-world, low-profile thumbsticks from APEM Inc. are used as examples.

More sophisticated equipment needs more precise controls

The need for better operator controls has accelerated due to two main trends: the growing complexity of workplace demands, and the adoption of advanced technologies. These trends are driving a need for not only more precise controls but also more complex controls, often with more axes of movement.

To illustrate this point, consider the marine gantry cranes that load and unload container ships. As the ships grow larger, cranes need to work faster to achieve an acceptable time in port (which directly affects profits). At the same time, tougher regulations necessitate improvements in safety and environmental impact.

The entire port environment is also undergoing change. The ships, trains, trucks, and other equipment at these ports have all added technologies that increase the need for high-precision coordination. For example, automated guided vehicles (AGVs) are being used to shuttle cargo around the port, and these AGVs require precision placement of that cargo.

To deal with all these factors, cranes are switching from hydraulic to electric operation. Not only does this increase speed and precision, but it also improves versatility by allowing more complex combinations of horizontal, vertical, and rotary travel.

Matching the operator controls to the equipment capabilities

To control this increasingly sophisticated equipment, operators need equally capable multi-axis controls, which must be precise, reliable, and easy to use.

Touchscreens are one option. They are easy to use and can readily accommodate multiple simultaneous inputs. However, touchscreens are sensitive and prone to accidental touches. Dirt, moisture, and extreme temperatures can cause malfunctions, and the screens are vulnerable to physical damage and electromagnetic interference. Most importantly, they do not offer tactile feedback, making them a poor fit for heads-up operation of heavy equipment.

Joysticks address many of these issues. Mounting a joystick in an armrest console or on a belly box makes for a comfortable, ergonomic input. With a proper design, they can stand up to tough environmental conditions. They can also deliver physical feedback to the operator, keeping the visual focus on the workspace.

However, traditional joysticks can take up a lot of room in cramped environments and can stick out in ways that make them susceptible to unintended operation. Even when space is plentiful, the fact that joysticks require operators to make relatively large movements puts a limit on their precision.

Thumbsticks address these issues by shrinking joysticks down to a more manageable size. Operated by the thumb or finger, these low-profile devices minimize the risk of accidental operation. They allow for precise and smooth inputs, and operators can easily manipulate two thumbsticks at once, solving the problem of multiple inputs.

Low-profile joysticks are particularly well-suited to portable controllers, such as belly boxes or handheld devices. But any application with limited space can benefit from their reduced size.

Selecting the right sensor

Of course, not all thumbsticks are created equal. For starters, they can use a variety of position sensors, including potentiometric (i.e., resistive), inductive, photoelectric, or Hall effect (i.e., magnetic). Each of these options has its own pros and cons:

- Potentiometric sensors are simple and inexpensive but have a limited lifespan.

- Inductive sensors are more reliable but are sensitive to temperature changes and electromagnetic interference (EMI).

- Photoelectric sensors are precise but are vulnerable to dust, moisture, and physical damage.

- Hall effect sensors are accurate and durable but can be affected by strong magnetic fields.

Considering all these tradeoffs, a Hall effect sensor is often the superior choice for high-precision sensing in a rugged environment. Hall effect sensors, operating at standard 3.3 or 5 volts direct current (DC) and implemented in conjunction with robust mechanicals, result in a device that can endure an expected lifetime of 10 million cycles.

Hall effect sensors place a thin strip of conductive material between two electrodes (Figure 1). When a current (I) flows through the strip, and a magnetic field (B) is applied perpendicular to it, a voltage difference (UH) is generated across the strip. This voltage difference is called the Hall voltage, which is proportional to the strength and direction of the magnetic field.

Figure 1: The Hall voltage (UH) is generated when a current (I) flows through a conductive strip, and a magnetic flux density (B) is placed perpendicular to the strip. (Image source: Wikipedia)

Figure 1: The Hall voltage (UH) is generated when a current (I) flows through a conductive strip, and a magnetic flux density (B) is placed perpendicular to the strip. (Image source: Wikipedia)

Some advantages of Hall effect sensors over other types of sensors in industrial joystick applications are:

- They are contactless and do not wear out over time.

- They are immune to dust, dirt, moisture, and vibration.

- They can measure linear and angular displacement with high accuracy and resolution.

- They can operate over a wide range of temperatures and voltages.

- They can be easily integrated with digital electronics and microcontrollers.

Hall effect sensors are particularly useful because they can detect both position and angle. This makes them well-suited to multi-axis controls, such as joysticks with not only X/Y controls but also a Z-axis center tap.

With that said, the sensor is only one design parameter to consider. Successful implementation of a Hall effect thumbstick requires careful consideration of several physical and electrical parameters.

Placing a thumbstick on the control panel

Sometimes a thumbstick can be mounted in a protected fixed location, like a control panel. More often, operators need to be close to the work, limiting the options to easily abused locations like consoles, vehicle armrests, pendants, and belly boxes.

If the thumbstick is used in a handheld enclosure, then care must be taken to protect it from drop damage. Basic precautions such as mounting it at the lightest end of the enclosure so it doesn’t hit the ground first or protecting it with a guard should be implemented for long-term reliability.

Vehicles are another risky situation. Controls onboard a pitching ship or vehicle may serve as an ill-advised handhold, so it is important to keep thumbsticks to the minimum possible height to avoid potentially dangerous accidental operation.

For any of these situations, thumbsticks should extend no more than about 50 millimeters (mm) (2 inches (in.)) above a panel face. There also must be sufficient clearance between the thumbstick and any other controls on the panel, with extra clearance if the operator might wear bulky gloves.

Ruggedizing a low-profile joystick

Industrial joysticks are often exposed to falling or directed water, so these devices need to be rated to at least IP66. This can be accomplished with a convoluted gaiter, i.e., a flexible boot that can expand and contract as the joystick moves (Figure 2).

A joystick may be dropped into a panel cut out or mounted from the rear. In either case, the underside of the panel must not be subject to water spray, excessive humidity, or dust, as this section of the joystick is not protected by the gaiter.

Figure 2: Drop-in mounting of a low-profile thumbstick (left) uses a bezel and countersunk screws; rear mounting (right) uses machine screws and accompanying nuts but no bezel. A convoluted gaiter provides protection to IP66. (Image source: Author, from APEM source material)

Figure 2: Drop-in mounting of a low-profile thumbstick (left) uses a bezel and countersunk screws; rear mounting (right) uses machine screws and accompanying nuts but no bezel. A convoluted gaiter provides protection to IP66. (Image source: Author, from APEM source material)

To maximize durability, designers should look for a device with a stainless-steel shaft, along with a similarly tough metal gimble and base mechanics and limiters. As noted earlier, handheld devices are prone to dropping, so the joystick should be tested to survive a 1 meter (m) free fall. Designers should also check for appropriate ratings for vibration, electromagnetic compatibility (EMC), and electrostatic discharge (ESD) protection in accordance with applicable IEC standards.

Resistance to extreme temperatures is also critical in rough environments. As an example, APEM’s XS Series low-profile joysticks are rated for an operating temperature of -30°C to +85°C, and a storage temperature of -40°C to +110°C.

Finally, if the thumbstick is to be used in a safety-critical application (which is often the case), look for a Safety Integrity Level (SIL) rating of SIL2 or better.

Human usability factors design considerations

Choosing the right materials and ergonomic design for the joystick can have a significant impact on usability. Designers need to keep in mind that the controller may be wet or dirty, and the operator may be wearing heavy gloves. Thus, the joystick cap should use a material like nylon to provide a durable yet easily gripped surface.

As illustrated in Figure 3, a variety of joystick caps are available for different scenarios. For example, the XS140SCA12A62000 fingertip joystick from APEM is equipped with a castle cap (left). This cap makes it easier for the operator to feel the main X and Y axis, which can help maintain a straight trajectory. In contrast, the XS140SDM12A62000 uses a fingertip cap that is suited to arbitrary motion.

Figure 3: The castle top provided on the XS140SCA12A62000 (left) and the flat cap provided on the XS140SDM12A62000 (right) are suited to linear and arbitrary motion, respectively. (Image source: Author, from APEM source material)

Figure 3: The castle top provided on the XS140SCA12A62000 (left) and the flat cap provided on the XS140SDM12A62000 (right) are suited to linear and arbitrary motion, respectively. (Image source: Author, from APEM source material)

Joysticks can also be equipped with a guided feel. Such a joystick moves more readily towards the main axes; moving away from these axes requires more force. Similarly, a joystick can be equipped with a centering force that increases the overall resistance of the joystick. For example, the APEM XS series low-profile joystick can be sprung to the center with a force as light as 1 newton (N), or as strong as 2.5 N.

Finally, a joystick can be configured with a variety of functions related to the center position:

- Adding a center tap function allows the joystick to be used like a button, which can simplify the control panel and enable more complex actions.

- Alternatively, the center tap can be used for a voltage test to ensure that the power supply is working properly.

- For applications that need an active/inactive status indicator, a center-detect function can determine whether the joystick is in use (this function should not be used for safety or security purposes).

Note that these options are mutually exclusive. It is important to identify which function is best suited to implementation on the joystick, and which other functions can be mapped to other controls.

Electrical design considerations

To ensure maximum reliability, look for a joystick with redundant Hall effect sensors. Further, the power supply must be carefully regulated. Should the power supply change outside of the specified tolerances, permanent damage to the sensors may occur, obviating the benefits of redundancy.

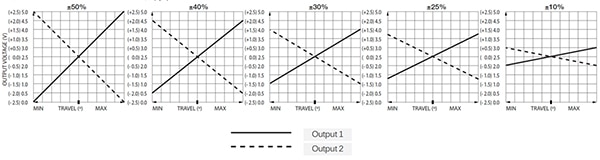

The voltage outputs of the joystick also requires thoughtful design. As a first step, the output signal type (e.g., analog or pulse width modulation (PWM)) should be selected, and the voltage scaled to match the expected inputs of the microcontroller unit (MCU) that will read these signals. Figure 4 illustrates an example of such possible output voltages. The output impedance should also be considered. A low load resistance (e.g., < 10 kilohms (kΩ)) creates a risk of high currents that could damage the sensor.

Figure 4: For multi-axis joysticks, the two output voltages (X/Y) should be scaled to match the MCU inputs. (Image source: APEM)

Figure 4: For multi-axis joysticks, the two output voltages (X/Y) should be scaled to match the MCU inputs. (Image source: APEM)

As noted earlier, Hall effect sensors are vulnerable to magnetic interference. A well-designed joystick will therefore incorporate internal magnetic screening. Care should be taken to decouple the power supply properly and employ adequate EMC shielding. Even with these measures in place, the joystick should not be mounted or operated near strong magnetic fields.

Conclusion

As industrial equipment grows more complex, designers need more robust controls to ensure the user interface has the level of precision, directional flexibility, and tactile feedback required for accurate control, while at the same being robust and reliable over temperature extremes and usage cycles. As shown, a low-profile joystick can be an excellent solution. With appropriate consideration of the position sensor, IP rating, electromagnetic isolation, and human usability, supported by careful design implementation, such a thumbstick can provide many benefits for a wide range of applications.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.