How Automation, Machine Learning, and Blockchain are Driving the Future of Electronics Manufacturing

Contributed By DigiKey's North American Editors

2023-05-23

Industry 4.0 relies on intelligent automation for manufacturing electronics. Increasingly capable automation is everywhere, from the edge to the cloud, in sensors, robots and cobots, programmable logic controllers (PLCs), and other equipment. Semiconductor wafers, integrated circuits, passive components, packaging, and electronic systems for consumer, green energy, automotive, medical, industrial, military/aerospace, and other applications depend on intelligent automation for their production. Unified manufacturing execution systems (MES) provide real-time monitoring, control, tracking, and documentation of the entire manufacturing chain, from raw materials to finished goods.

The cyber-physical automated systems in Industry 4.0 extend beyond traditional manufacturing activities and rely on various forms of machine learning (ML) ranging from deep reinforcement learning in the cloud to tinyML on the edge for flexible production, continuous improvement, and consistently high quality. The number of layers of connectivity is growing, and the combination of edge computing, the Industrial Internet of Things (IIoT), and cloud computing is increasing the challenges related to cyber security. Blockchain has recently entered the picture for comprehensive and secure supply chain management.

This article looks at key automation trends in electronics manufacturing, including the increasing layers of connectivity, the growing need for cybersecurity, the specialized implementations of ML being deployed, and how traceability and MES support real-time production metrics and analytics. Along the way, some of the technologies needed to fully realize the promise of Industry 4.0 for mass customization with high quality and low costs are reviewed, including how Dig-Key supports the needs of automation system designers with a wide range of solutions. It closes with a look at how blockchain is used to deploy highly secure enterprise-wide supply chain management systems.

Increasing layers of connectivity

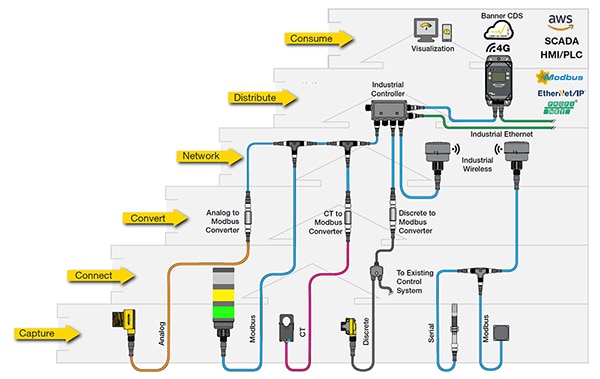

The IIoT in industry 4.0 includes more wired and wireless network layers for sensor networks, autonomous mobile robots (AMRs), and other systems. For example, IO-Link was developed to provide a simplified wired network connection for the massive number of sensors, actuators, indicators, and other previously unconnected legacy edge devices to higher-level networks like Ethernet IP, Modbus TCP/IP, and PROFINET. With IO-Link, the inputs and outputs (IOs) of these devices are captured and converted to the IO-Link protocol for serial connectivity defined in IEC 61131-9 with a single 4- or 5-wire unshielded cable defined in IEC 60974-5-2 (Figure 1). In addition to providing a new networking layer to capture more granular information about factory processes, IO-Link supports rapid deployment and remote configuration, monitoring, and diagnostics of connected devices to support line and process changes needed for mass customization in Industry 4.0 factories.

Figure 1: IO-Link can be used to connect sensors and other devices using diverse interfaces to Ethernet, PROFINET, or Modbus networks. (Image source: Banner Engineering)

Figure 1: IO-Link can be used to connect sensors and other devices using diverse interfaces to Ethernet, PROFINET, or Modbus networks. (Image source: Banner Engineering)

Wireless IIoT devices, from sensors to robots, also contribute to the growing networking layers. Various wireless protocols, including Wi-Fi, 5G, LTE, and others, are used in modern factories. For example, AMRs use a combination of onboard sensors and Wi-Fi connectivity to understand their environment, identify possible obstacles and move safely and efficiently from place to place. Collaborative robots (cobots) are designed to work with people to improve operational efficiency and often require wireless connectivity. In some cases, AMRs move cobots from task to task as needed (Figure 2).

Figure 2: An AMR (bottom) can navigate from place to place using a combination of onboard sensors and wireless connectivity and pick up and move a cubit (top) to a new workstation. (Image source: Omron)

Figure 2: An AMR (bottom) can navigate from place to place using a combination of onboard sensors and wireless connectivity and pick up and move a cubit (top) to a new workstation. (Image source: Omron)

Increasing cyber dangers

The increasing layers in industrial networks, combined with the explosion in the number of connected devices, are resulting in a growing number of security threat vectors and increasing cyber dangers. Several industrial and IoT-specific security standards and methodologies have been developed, including International Electrotechnical Commission (IEC) 62443 and the Security Evaluation Standard for IoT Platform (SESIP).

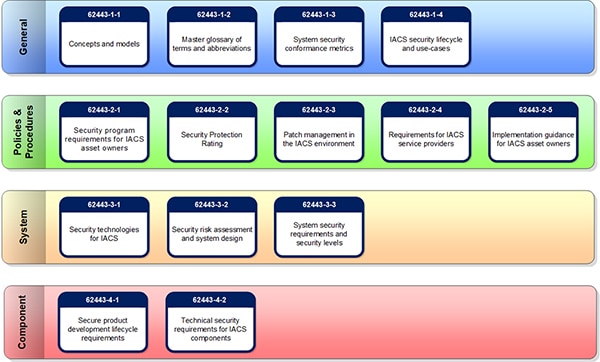

IEC 62443 is a series of standards developed by the International Society of Automation (ISA) 99 committee and approved by the IEC. IEC 62443 is an 800-plus-page series of standards for Industrial Automation and Control Systems (IACS) in 14 subsections and four tiers (Figure 3). Key sections that define the product development and security requirements for components are:

- IEC 62443-4-1: Product Security Development Lifecycle Requirements – defines a secure product development lifecycle including initial requirements definition, secure design and implementation, verification and validation, defect and patch management, and end-of-life.

- IEC 62443-4-2: Security for Industrial Automation and Control Systems: Technical Security Requirements for IACS Components – specifies security capabilities that enable a component to mitigate threats for a given security level.

Figure 3: IEC 62443 is a comprehensive set of IACS security standards. (Image source: IEC)

Figure 3: IEC 62443 is a comprehensive set of IACS security standards. (Image source: IEC)

SESIP is published by the GlobalPlatform and defines a common structure for evaluating the security of connected products and addresses IoT-specific compliance, security, privacy, and scalability challenges. SESIP provides clear definitions of security functionality on components and platforms in the form of Security Functional Requirements (SFRs). It also provides strength metrics that measure robustness against attacks in the form of SESIP “levels” from 1 to 5, with 1 being self-certification and 5 corresponding to extensive testing and third-party certification.

ML from the cloud to the edge

ML is a key enabler of intelligent automation, supporting continuous process improvements and high-quality products. The use of neural networks is a well-established ML technique in Industry 4.0. It’s beginning to be supplemented with deep reinforcement learning in the cloud. Deep reinforcement learning adds a framework of goal-oriented algorithms to a neural network core. Initially, reinforcement learning was confined to repeatable environments like playing games; today, algorithms can operate in more ambiguous environments in the real world. In the future, advanced reinforcement learning implementations may achieve artificial general intelligence.

ML is not just in the cloud; it’s reaching onto the factory floor to the edge. The expansion slots in industrial PCs and programmable controllers on the factory floor increasingly host ML and AI accelerator cards for intelligent process control.

Tiny machine learning (tinyML) is optimized for deployment in low-power applications. The use of tinyML in sensor applications is growing rapidly. One example of a tinyML application is IIoT sensor analytics in edge devices powered by batteries or energy harvesting. Arduino offers a Tiny Machine Learning Kit that includes an Arduino Nano 33 BLE Sense board containing an MCU and a variety of sensors that can monitor movement, acceleration, rotation, sounds, gestures, proximity, color, light intensity, and movement (Figure 4). An OV7675 camera module and an Arduino shield are also included. The onboard MCU can implement deep neural networks based on the TensorFlow Lite open-source deep learning framework for on-device inference.

Figure 4: Arduino’s Tiny Machine Learning Kit is designed for developing IIoT sensor applications. (Image source: DigiKey)

Figure 4: Arduino’s Tiny Machine Learning Kit is designed for developing IIoT sensor applications. (Image source: DigiKey)

Real-time metrics and analytics

Real-time metrics and analytics are essential aspects of intelligent automation. Traceability 4.0 combines product visibility, supply chain visibility, and line-item visibility from previous generations of traceability and provides a complete history of all aspects of a product. In addition, it includes all machine and process parameters and supports overall equipment effectiveness (OEE) metrics that optimize manufacturing processes (Figure 5).

Figure 5: Traceability 4.0 is a comprehensive implementation that supports the diverse requirements of Industry 4.0 operations. (Image source: Omron)

Figure 5: Traceability 4.0 is a comprehensive implementation that supports the diverse requirements of Industry 4.0 operations. (Image source: Omron)

Traceability is vital in many industries, from medical device manufacturing to automotive and aerospace. In the case of medical devices, regulatory requirements demand extensive tracking and traceability. Automobiles and aerospace systems can have tens of thousands of parts to track. It’s not just part history; traceability includes tracking individual part geometric dimensioning and tolerancing (GD&T). GD&T enables precision manufacturing and the installation of parts based on their exact GD&T values, supporting high-precision assemblies for industries like aerospace and automotive manufacturing.

Traceability can improve the accuracy and efficiency of implementing product recalls. It enables the manufacturer to identify all the affected products and the supplier or suppliers of any defective components.

Corrective and preventative actions can be accelerated through the use of traceability. Like product recalls, knowing the complete provenance of products enables manufacturers to efficiently target and schedule service and maintenance activities for products in the field.

Traceability and MES

Unified MES implementations incorporating traceability can produce a searchable database of all the information related to individual products, including as-planned designs and as-built results. For example, traceability is used to track individual components and materials as they arrive, including inbound quality testing data, location of the supplying factory, and so on, before production starts. MES verifies that information based on the planned design and feeds into kitting operations and work in process databases.

Traceability data supplied by the IIoT combined with MES supports the mass customization of products in Industry 4.0. MES enables the right materials, processes, and other resources to be at the right place to ensure the lowest production cost and highest quality result. Also, MES and traceability can combine and demonstrate compliance with government regulations and make the data readily accessible to auditors or others as required.

Blockchain

A blockchain is a decentralized, or distributed, digital ledger system for recording transactions between multiple parties in a tamperproof and verifiable manner. Any transactions where trust is important, like supply chain management, are potential uses for blockchain. In a supply chain with many participants, blockchain can improve transaction efficiency and make transactions verifiable and tamperproof. Two examples of the benefits of using blockchain in supply chain activities include:

Replacement of manual processes. Manual paper-based processes that rely on signatures or other forms of physical verification can potentially be improved using blockchain. The limitation is that the universe of participants in the ledger must be finite and easily identifiable. A delivery company with a constantly changing database of unfamiliar customers may not be a good candidate for blockchain. A manufacturing operation with a finite and slowly changing group of trusted suppliers is a good candidate.

Strengthening traceability. Blockchain can provide a good tool for improving supply chain transparency and meeting growing regulatory and consumer information requirements. For example, the blockchain can support the Drug Supply Chain and Security Act and the unique device identifier mandate from the U.S. Food and Drug Administration. In the automotive and other industries, suppliers throughout the supply chain can be involved in implementation of recalls, and blockchain can provide a good tool for implementing the Traceability Guideline published by the Automotive Industry Action Group.

Summary

The intelligent automation that’s the foundation of Industry 4.0 relies on numerous technologies for its implementation, including a growing number of network layers with wired and wireless connectivity that result in increasingly complex cyber security threats. In addition, machine learning is being implemented from the edge to the cloud to support real-time metrics and analytics, including traceability and unified MES. Finally, blockchain technology is being introduced to support tamperproof and verifiable databases.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.