Ensure Connectivity in Harsh Environments with Bonded-Pair Ethernet Cables

Contributed By DigiKey's North American Editors

2023-09-26

With the migration to the Industrial Internet of Things (IIoT), the demand for increased reliability and performance in sensor and actuator-rich industrial environments presents growing challenges for developers looking for robust connectivity solutions. Noisy electrical environments limit wireless methods, while harsh physical environments complicate the use of conventional cabling approaches. Designers require a more effective connectivity solution, able to maintain reliability and performance.

One option is to use bonded-pair Ethernet cabling that prevents the separation of the twisted wire pairs to maintain signal integrity.

This article describes the challenges facing designers as they consider cabling options for harsh environments. It then shows how they can address these challenges with bonded-pair Ethernet cables, using examples from Belden to illustrate the technology’s characteristics and performance relative to classic Ethernet cabling.

Evolving industrial environments challenge network reliability and performance

The need for a greater variety and number of sensors and actuators in the evolving IIoT has compounded challenges facing industrial network designers. Along with the ongoing need for reliable connectivity, industrial networks need to deliver both real-time performance and higher throughput as vision-based systems join high-precision sensors to play a critical role in multiple phases of the manufacturing process. While network technologies such as the IEEE 802.1 time-sensitive networking (TSN) standards help designers meet requirements for deterministic Ethernet performance, 10 gigabit (Gbit) Ethernet networks are becoming the standard as industrial environments experience greater data volume, velocity, and variety.

Ensuring network reliability and performance in the industrial environment remains challenging due to the nature of the typical factory’s electrical and physical environment. In this environment, machine-generated electrical noise and power disturbances combine with various sources of electromagnetic interference (EMI) and radio frequency interference (RFI) to compromise communications signal integrity. Physically, the factory floor presents significant challenges in the form of fuel, oil, solvents, and other chemicals, as well as moisture, high temperatures, and rapid temperature changes from operating machinery, industrial processes, and weld splatter.

In building their communications networks, factory network designers rely on communications cables that only superficially share similarities with cables intended for installation in commercial buildings. As in commercial buildings, a riser-rated cable, known as Communications Multipurpose Cable, Riser (CMR), serves for cable runs through risers or vertical shafts in industrial plants. Similarly, a plenum-rated cable, known as Communications Multipurpose Cable, Plenum (CMP), is a higher rated cable needed to restrict flame propagation and smoke in horizontal cable runs through spaces below floors or ceilings.

Unlike most commercial building installations, however, cable runs in the industrial environment are particularly susceptible to mechanical stress from continued vibration, flexing, abrasion, and crushing from normal factory operations. Industrial network designers have long relied on diverse cable-jacket insulation materials to achieve the required balance between cost and performance in their networks.

Industrial cable characteristics

Although cable insulation materials vary to meet specialized requirements, fluorinated ethylene polymer (FEP) and polyvinyl chloride (PVC) are two materials commonly used in industrial cable jackets. In CMP-rated cables, FEP is often used due to its smoke and flame-retardant characteristics. The use of FEP in communications cable jackets not only reduces flame but also limits the spread of heavy smoke from fires through air ducts. Along with strong chemical resistance, FEP cables typically tolerate a wide ambient temperature range. For example, Belden’s CMP-rated four-pair FEP-jacketed DataTuff 7931A Ethernet cable (7931A 0101000) is specified for an operating temperature range of -70 to +150°C.

CMR-rated cables are typically insulated with PVC, which offers lower cost while delivering suitable durability and resistance to chemicals, heat, and water. PVC typically exhibits a more restricted operating temperature, in line with its typical usage in risers. For example, Belden’s CMR-rated four-pair PVC-jacketed DataTuff 7953A Ethernet cable (7953A 0101000) is specified for an operating temperature range of -40 to 75°C.

Besides FEP and PVC, other materials are often used separately or together to support specific requirements. For example, for its two-pair DataTuff 7962A Ethernet cable (7962A 1SW1000), Belden combines a thermoplastic elastomer (TPE) outer jacket, polyethylene (PE) inner jacket, and polyolefin (PO) wire insulation to provide a tough, flame-retardant, oil-resistant cable that is suitable for hazardous environments.

The choice of jacket material is only one of several key decision points in the selection of cable for industrial Ethernet networks. As mentioned earlier, industrial communications cables can undergo significant mechanical stress that results in increased signal noise in conventional twisted-pair cable. This familiar cable type relies on the reduction in crosstalk and interference susceptibility found when a pair of wires are twisted together. In practice, however, the stresses of installation and typical day-to-day operation in the industrial environment can cause separation between the paired wires (Figure 1).

Figure 1: Conventional twisted-pair cable reduces crosstalk and noise while the paired wires remain close together (top), but the wires typically separate (bottom) after repeated bending, flexing, and pulling. (Image source: Belden)

Figure 1: Conventional twisted-pair cable reduces crosstalk and noise while the paired wires remain close together (top), but the wires typically separate (bottom) after repeated bending, flexing, and pulling. (Image source: Belden)

As the conductor-to-conductor spacing, or centricity, increases due to continued bending, flexing, or pulling, the noise-canceling effect of the twisted pair is significantly degraded. Over time, signal integrity becomes compromised, affecting the reliability of transmissions across the network. Belden’s alternative to conventional twisted-pair communications cable is designed to maintain signal integrity despite the rigors of installation and ongoing usage.

Bonded-pair technology offers immunity to stresses

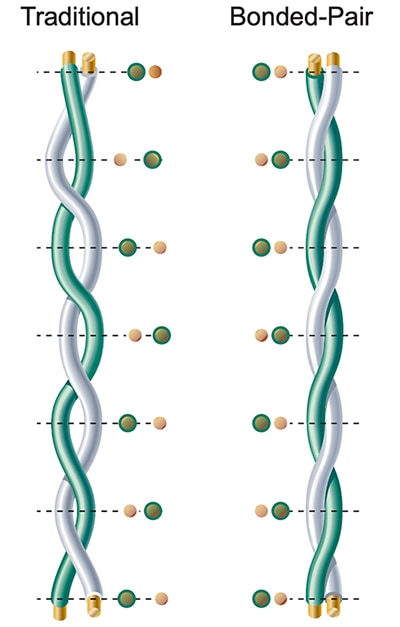

Belden’s patented bonded-pair technology creates an actual bond between the wires in each pair to maintain an optimum centricity for all twisted pairs in a communications cable, avoiding the gaps that can compromise the signal integrity (Figure 2).

Figure 2: Unlike conventional twisted-pair technology (left), Belden’s bonded-pair technology (right) ensures that the spacing between paired wires in a cable remains fixed despite bending, flexing, or pulling. (Image source: Belden)

Figure 2: Unlike conventional twisted-pair technology (left), Belden’s bonded-pair technology (right) ensures that the spacing between paired wires in a cable remains fixed despite bending, flexing, or pulling. (Image source: Belden)

Belden’s bonded-pair technology results in cables with a pull tension resistance that is typically 40% stronger than conventional Ethernet cable. At the same time, a Belden bonded-pair cable can be safely bent or flexed along a bend radius as tight as four times the outer diameter of the cable. In contrast, a regular Ethernet cable’s bend radius is typically limited to ten times the outer diameter.

The added strength imparted by bonded-pair technology translates to an ability to maintain reliability despite continued stress from flexing during installation or normal operation. Although the industry lacks a standard for measuring the ability to withstand flexing, Belden created a flex test designed to simulate common industrial operating conditions.

Belden engineers first subjected a 15 foot (ft.) length of bonded-pair cable to a tight 3 inch (in.) bend, before subjecting it to a multiaxial movement of 10 feet per second (ft./s) for 28,800 cycles per day. The Belden engineering team continually monitored the cable-under-test for shorts, voltage drops, and other issues at eight points along its length. They stopped the test after 10,075,000 flex cycles without having detected any physical or electrical failures.

The robust performance of bonded-pair cable becomes evident when comparing its electrical performance to conventional cable. Using link margin as a metric, tests showed that Belden bonded-pair cable maintains performance before and after installation (Figure 3, left). In contrast, conventional twisted-pair cables that pass performance tests on the reel can fail following installation due to pair separation after the cable has been subjected to the normal pulling, bending, and flexing stresses of installation (Figure 3, right).

Figure 3: In a Belden bonded-pair cable, link margin remains high in the individual data pairs (blue/yellow/green/red) before and after installation (left), while conventional twisted-pair cables that test well on the reel subsequently show a dramatic reduction following installation due to pair separation caused by installation stress. (Image source: Belden)

Figure 3: In a Belden bonded-pair cable, link margin remains high in the individual data pairs (blue/yellow/green/red) before and after installation (left), while conventional twisted-pair cables that test well on the reel subsequently show a dramatic reduction following installation due to pair separation caused by installation stress. (Image source: Belden)

Compared to a bonded-pair cable, a conventional twisted-pair cable can also show erratic frequency-dependent impedance fluctuations due to the gaps created between wire pairs during installation and handling (Figure 4).

Figure 4: The impedance of Belden’s bonded-pair cable (left) remains stable before and after installation, compared to the handling-induced impedance changes of conventional industrial cable (right). (Image source: Belden)

Figure 4: The impedance of Belden’s bonded-pair cable (left) remains stable before and after installation, compared to the handling-induced impedance changes of conventional industrial cable (right). (Image source: Belden)

In normal operation, non-shielded bonded-pair cable can maintain noise protection, often at a lower cost than conventional shielded cable. For industrial network designers, bonded-pair cable’s noise protection helps ease routing constraints compared to conventional shielded industrial cable. For example, guidelines from ODVA (formerly Open DeviceNet Vendors Association) recommend routing conventional shielded cable more than 5 ft. from electromagnetic sources to avoid interference. In contrast, non-shielded bonded-pair cable’s noise protection lets network designers route this cable within 6 in. or less of a source without compromising signal integrity.

Conclusion

Harsh electrical and physical industrial environments complicate the selection of cables that are able to maintain the required signal integrity as IIoT data rates increase. As shown, Belden’s patented bonded-pair technology provides an effective solution able to maintain connectivity performance more effectively than conventional industrial Ethernet cables.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.