Energy Harvesting in the Smart Grid

Contributed By DigiKey's European Editors

2015-09-09

The Smart grid is slowly becoming reality as more networks roll out across Europe. The European Union aims to replace at least 80% of electricity meters with smart meters by 2020 to reduce emissions by almost 10% and annual household energy consumption by similar amounts.

Nearly 200 million electricity smart meters and 45 million gas meters will be rolled out across Europe by 2020 so that over 70% of all consumers will use them. With the average cost of installing a smart meter at between €200 and €250, this is an investment of €45 billion, but this is just half the story. The capital expenditure (capex) is high, but so is the operational expenditure (opex) of making sure the smart grid delivers all the vital data.

Part of the drive to the smart grid is to create a more efficient use of renewable resources such as solar and wind power. With many more wind farms and solar power plants being installed across Europe, there is an increasing need to have more accurate data on the usage of power in homes, offices and factories in order to make best use of these renewable sources. This is creating a network of smart meters that monitor the power into a home, and also networks of wireless sensors that can provide more detailed data on the power usage. This is also driving the rollout of gateway devices, often in the local sub-stations, which collate the data and send it to the electricity providers in real time, often using the electricity lines themselves with power line controllers.

All of this also represents an opportunity for energy harvesting within the electronic systems in the grid. One of the key costs of a smart grid network is the maintenance and replacement of batteries across the meters and sensors of the network. Using energy harvesting technology in both the home meter and in the more industrial sub-stations can dramatically reduce the ongoing costs of running the smart grid.

This can make use of several different energy harvesting technologies, from solar cells to power wireless sensor networks to thermal generators that convert a temperature difference into electrical power for a sub-station.

Solar power can be used in a number of ways, from small cells on individual sensors to a bigger array that powers a gateway for collecting data from across the network.

Parallax’s Solar Panel array can produce up to a maximum of 34 watts of electrical energy from a rooftop installation to power the network equipment. It is rugged enough for permanent power production (including rooftop installations), and can be used in many portable applications as well. It uses twelve 125 mm (~5”), 2.85 watt, monocrystalline solar cells with an efficiency around 18.5% mounted on a UV-stabilized polycarbonate base with cover panels to provide outdoor durability. A custom-milled base panel simplifies assembly and protects the solar cells and while the maximum power output is 6.3 VDC at 5.4 A, it is possible to daisy-chain multiple units to provide higher voltage, current or power, depending on the needs of the sensor network gateway.

Figure 1: The solar panel array from Parallax can provide 34 W of power.

To convert the power for the network gateway, a Solar Energy Harvesting development kit such as the eZ430-RF2500-SEH from Texas Instruments can be used. The system manages and stores additional energy in a pair of thin-film rechargeable batteries that can deliver enough power for 400+ transmissions, even in the dark. These act as energy buffers that store the energy while the application is sleeping and has light available to harvest. The batteries have a very low self-discharge, making them suitable for an energy harvesting system. The board is a complete USB-based MSP430 wireless development tool and provides all the hardware and software necessary to use the MSP430F2274 microcontroller and CC2500 2.4 GHz wireless transceiver. It includes a USB debugging interface that allows for real-time, in-system debugging and programming for a 16 MHz low-power MSP430 microcontroller and it is also the interface to transfer data to a PC from the wireless system. Integrated temperature and RF signal strength indicators can be used to monitor the environment, and many external sensors can be used to collect additional data.

Figure 2: The TI eZ430 energy harvesting development board can support either solar cells or thermoelectric generators in the smart grid.

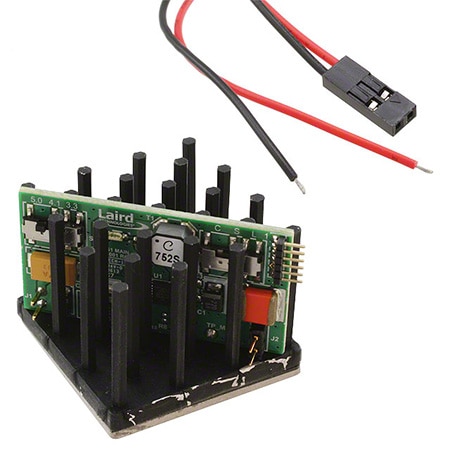

The board also links easily to the WPG-1 thermal heat energy harvester from Laird Technologies via a 6-pin connector. The WPG-1 is a self-contained thin-film thermoelectric power generator that can be used for wireless sensor networks as well as gateways in the sub-station. It provides up to 1.5 mW of usable output power and can handle a wide range of load resistances.

The generator uses an ultra-low-voltage step-up converter to provide usable output power at temperature differentials under 20°K, making it suitable for tapping the temperature difference between the inside and outside of a building. The output power can be regulated to accommodate three voltage set points: 3.3 V, 4.1 V or 5.0 V, and the integrated circuit board includes DIP switches for setting the output voltage. Electrical connections can be made using the on-board 2- or 6-pin connector that works with the eZ430 development board.

Figure 3: The WPG-1 from Laird Technologies generates power from a temperature difference as small as 20°K.

Another way is to build a dedicated power management system that can handle a variety of energy harvesting sources. The bq25570 from Texas Instruments is specifically designed for efficient operation in the microwatts and milliwatts range that comes with high output impedance DC sources such as solar cells or thermal electric generators (TEG) without putting too much strain on those sources. The battery management in the device ensures that a rechargeable battery is not overcharged by this extracted power, with voltage boosted or depleted beyond safe limits by a system load. In addition to the highly efficient boosting charger, the bq25570 integrates a highly efficient, nano-power buck converter for providing a second power rail to systems such as wireless sensor networks (WSN) which need a consistent voltage source.

The bq25570 also implements a programmable maximum power point tracking (MPPT) sampling network to optimize the transfer of power into the device. The fraction of open circuit voltage that is sampled and held can be controlled by pulling a pin high or low (80% or 50%, respectively) or by using external resistors. This sampled voltage is maintained via internal sampling circuitry and held with an external capacitor. For example, solar cells typically operate with a maximum power point (MPP) of 80% of their open circuit voltage, so setting the MPPT threshold to 80% allows the device to regulate the voltage on the solar cell to ensure that the VIN_DC voltage does not fall below a set voltage. An external reference voltage can also be used to allow an external microcontroller to implement a more complex MPPT algorithm.

Figure 4: The bq25570 from TI can be used to build an optimized power management controller that supports maximum power point tracking algorithms for efficient power matching.

The bq25570 is designed with the flexibility to support a variety of energy storage elements, as the energy that is harvested can often be sporadic or time varying. Systems will typically need some type of energy storage element, such as a re-chargeable battery or supercapacitor that can provide steady, reliable power to the system and also handle any peak currents. To prevent damage to the storage element, both maximum and minimum voltages are monitored against the internally set undervoltage and user programmable overvoltage levels, and can flag a situation where the voltage on an energy storage battery or capacitor drops below a pre-set critical level. This should trigger the reduction of load currents to prevent the system from entering an undervoltage condition.

All of this is packaged in a small footprint 20-lead 3.5 mm x 3.5 mm QFN package (RGR) so that the power management element can be easily installed alongside the energy harvesting source.

Conclusion

The use of energy harvesting sources to power the different elements of the smart grid can provide considerable advantages for system suppliers and power companies. Dramatically reducing the need to replace the batteries in wireless sensor networks, or even eliminating it all together, can save substantial operating costs. Energy harvesting from large arrays of solar cells or thermoelectric generators, coupled with the appropriate power management and energy storage devices can provide maintenance-free power for both the networks that collect the essential data for the smart grid and the gateways that collate and deliver the data to the operators.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.