Comparing Axial Fans and Centrifugal Fans

2022-03-22

When it comes to dealing with excess heat in a system, fans are a go-to thermal management solution for removing unwanted heat and providing cooler air across critical components. Outside of throttling system power, adding heat sinks, or utilizing pipes or cold plates, there often remains a need to generate forced air to further cool things down.

This presents an engineer with the choice between an axial fan design or a centrifugal fan design. While not an overly complex decision, this article aims to outline the basic operating principles of each type, discuss their common applications and uses, and summarize their advantages and disadvantages.

Axial fan basics and applications

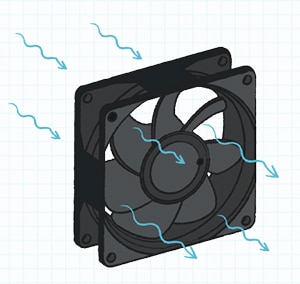

Sometimes referred to as propeller fans, axial fans feature skewed blades mounted on a rotating axis (or shaft) which is driven by a motor. Axial fans operate by pulling air in one end and forcing it out the other in a parallel direction to the axis (Figure 1). Tubeaxial or vaneaxial fans are other common terms, which are simply axial fans intended to fit in a duct.

Figure 1: Basic airflow direction of an axial fan. (Image source: Same Sky)

Figure 1: Basic airflow direction of an axial fan. (Image source: Same Sky)

Axial fans are available in virtually any size from board level to room size, and while dependent on size, typically do not require much power to operate. Offered in both AC and DC versions, AC fans utilize line current and are generally rated over 100 V, while DC fans carry much lower voltages in the 3 to 48 Vdc range and are usually driven by batteries or a power supply.

The airflow that axial fans produce is high volume, but low pressure. This high-volume, low-pressure output makes them well-suited for cooling equipment and spaces both small and large due to airflow being evenly distributed in a defined area. Axial fans can often be found cooling computers or datacenter equipment, utilized in HVAC, AC condensers, or heat exchange units, and used for spot cooling in industrial systems. They can also serve as exhaust fans.

Centrifugal fan basics and applications

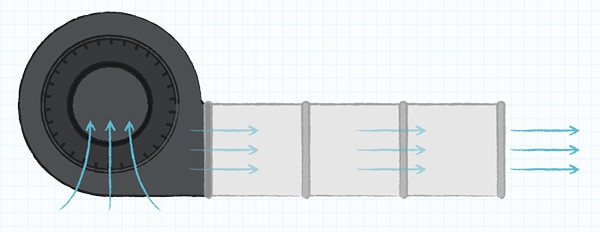

Also known as radial fans or centrifugal blowers, centrifugal fans feature impellers contained within a motor-driven hub that intakes air into the housing and then expels the air from an outlet at a 90-degree angle (perpendicular) to the intake (Figure 2).

Figure 2: Basic airflow direction of a centrifugal fan. (Image source: Same Sky)

Figure 2: Basic airflow direction of a centrifugal fan. (Image source: Same Sky)

As high-pressure, low-volume output devices, centrifugal fans essentially pressurize air within the fan housing, which works to produce a steady, high-pressure stream of air, but at more limited volumes compared to axial versions. Because they expel air from an outlet, they are ideal for targeting airflow in a specific area to cool a particular part of the system that generates more heat like a power FET, DSP, or FPGA. Similar to their axial counterparts, they are also available in AC and DC versions with a range of sizes, speeds, and footprints, but typically consume more power. Their enclosed design does offer some additional protection to the various moving parts, making them a reliable, durable, and damage resistant option.

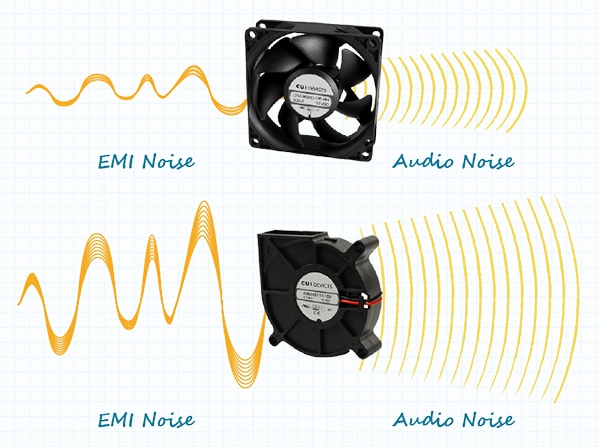

Both centrifugal and axial fans produce audible and electromagnetic noise, but centrifugal designs tend to be louder than axial models. Since both fan designs use motors, EMI effects can impact system performance in sensitive applications.

A centrifugal fan’s high-pressure, low-volume output ultimately makes it ideal for airflow in concentrated areas like pipes or ductwork (Figure 3), or for ventilation and exhaust. This means they work well in air conditioning or drying systems, while their added durability mentioned earlier can allow for operation in harsh environments that deal with particulates, hot air, and gasses. In terms of electronic applications, centrifugal fans are commonly utilized in laptops due to their low profile and higher directionality (airflow expelled at 90 degrees from the intake).

Figure 3: Centrifugal fan used in ductwork. (Image source: Same Sky)

Figure 3: Centrifugal fan used in ductwork. (Image source: Same Sky)

Fan EMI and noise considerations

Electromagnetic interference (EMI) generated by fans is an important design consideration to take into account early on. All fans can generate either radiated EMI from the fan itself or conduced EMI from the power leads. Uncontained magnetic fields (UMF) arising from the motor magnets and stator windings can also result in interference. While application specific, careful consideration in the early stages of design will save time and money down the road. In general, DC fans create less EMI than their AC fan counterparts.

Figure 4: Axial fans tend to produce less noise than centrifugal blowers. (Image source: Same Sky)

Figure 4: Axial fans tend to produce less noise than centrifugal blowers. (Image source: Same Sky)

Another application-specific design consideration is the audible noise generated by fans. Noise varies by application, density of the components, placement in a system, size of the fan, amount of air moved, bearing types used, etc. Bearings in a fan not only affect acoustics but can impact the lifespan and potential applications. Audible noise can often be mitigated by better fan placement, mechanical isolation, or the use of air inlet grills or outlet diffusers. A good rule of thumb is, the higher the CFM or airflow, the higher the audible noise. With that being said, if a larger fan and a smaller fan both have similar CFM ratings, the larger fan will typically result in a quieter overall solution. As mentioned earlier, axial fan designs are usually quieter than centrifugal options.

Final comparison

To help wrap things up, here is a quick comparison of the various advantages, disadvantages, and characteristics of axial and centrifugal fans. Deciding on the best option will truly depend on the intended application, space available, and overall thermal requirements of the end system.

|

Figure 5: Comparing basic characteristics of axial and centrifugal fans. (Image source: Same Sky)

Conclusion

Keeping electronic components that produce unwanted heat cool can be effectively managed with either axial fans or centrifugal fans. Both have been proven in the field through many years of use and continuous improvement. Same Sky offers a wide range of dc axial fans and centrifugal blowers with a variety of frame sizes and airflow ratings to help match an engineer’s specific thermal requirements.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.