Breaking Down Control and Protection Options for DC Fans

2020-10-13

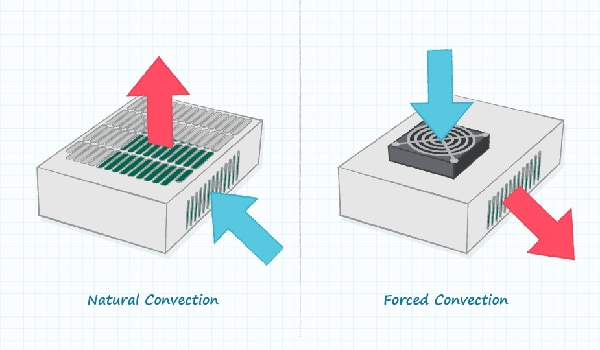

As a well-known and widely implemented thermal management device, dc fans can be used individually, in series, or in parallel to provide forced-air convection cooling. Their versatility and relatively simple operation have made them a solid choice to improve an end application’s thermal profile for many years. Rooted in basic physics, the moving air that fans produce is effective in cooling components by absorbing heat and then transferring that heat out of a device to be dissipated. However, their effectiveness is impacted by several factors and engineers can benefit from a better understanding of the features and options available for dc fans to improve their reliability and efficiency.

Figure 1: Natural convection vs forced-air convection cooling (Image source: Same Sky)

Figure 1: Natural convection vs forced-air convection cooling (Image source: Same Sky)

To begin the dc fan selection process, an engineer will need to conduct some basic thermal analysis in order to calculate the minimum airflow requirement. A typical thermal analysis might include modeling of heat sources, ambient conditions, and temperature rise. Other factors such as the size of fan, its orientation, and the airflow path within the application will also need to be considered to ensure a suitable solution is implemented. Same Sky’ blog, “Understanding Airflow Fundamentals for Proper Dc Fan Selection” provides further details on thermal analysis and the selection process.

With the thermal analysis complete and the appropriately sized and rated fan chosen, all that is left is to power the fan and let it get to work, correct? While operating a fan full time can serve its purpose in certain scenarios, continuous forced-air cooling does not generally provide an energy-efficient or long-term solution. Today’s dc fans offer designers a suite of control, monitoring, and protection options to enhance their thermal management capabilities. The rest of this article will aim to cover these features, so designers can benefit from more-advanced fan control techniques.

On/off cycling

As noted above, full-time fan operation will certainly keep temperature-sensitive components cool but ignores both the power it consumes and the fact that fans having moving parts with finite operating lives. When fans are running, they also produce audible noise that might be unwanted in a variety of applications and environments.

On/off cycling of a fan around a temperature setpoint is an alternate approach that can mitigate some of the shortcomings of continuous fan operation. The on/off fan control technique can save power by limiting run time, put less strain on a fan’s moving components, and reduce audible noise when the fan cycles off as the temperature drops below the setpoint.

However, on/off fan control is also too simplistic of an approach to forced-air cooling in many ways and has its own set of shortcomings. First of all, the on/off control technique introduces cycles of hot and cold to the temperature-sensitive components. Thermal cycling can be as harmful or worse for critical components than operation at constant elevated temperatures. This is because thermal cycling creates differences in temperature-coefficients that cause additional stress on materials and solder joints, leading to premature failure.

Next, is the factor of unavoidable thermal overshoot. This is the time delay between the fan switching on and when the forced air it produces actually begins to cool. During this time delay, overheating of the components can occur unless the “fan on” setpoint is lowered. Also, by lowering the setpoint, the time the fan is powered on and creating audible noise is increased. Finally, to avoid rapid on and off switching around the setpoint, often known as ‘chattering’, hysteresis will need to be implemented.

The graph below helps to illustrate the thermal overshoot dilemma caused by thermal lag in on/off fan control applications. This graph plots the desired setpoint temperature with a step change (light blue), along with the on/off cycling of the fan (green), and the actual temperature (dark blue).

Figure 2: On/off fan cycling can lead to thermal overshoot and lag (Image source: Same Sky)

Figure 2: On/off fan cycling can lead to thermal overshoot and lag (Image source: Same Sky)

Today’s fan control options

Today’s dc fans afford designers an array of control and protection options that allow for more fine-tuned thermal management systems. These advanced designs take basic on/off fan control to a new level of performance, efficiency, and reliability. Protection options are also available that detect problems before they cause damage to the fan and the components the fan is cooling. Some of the most common fan control and protection options are covered below:

Pulse-width modulation

Pulse-width modulation (PWM) is a common method used to control and change the fan speed based on varying thermal conditions. PWM-based variable-speed control results in better operating efficiency when paired with advanced control algorithms which can adapt to operational dynamics that match fan speed to thermal load.

On/off fan control can also be upgraded using this method by adopting proportional-integral-derivative (PI and PID) closed-loop control strategies. These strategies help to avoid thermal overshoot or undershoot despite load changes by ensuring the airflow keeps conditions at the desired setpoint temperature.

Embedded tachometer signal

Used for closed-loop feedback and more advanced fan control, embedded tachometer senses and reports on a fan’s rotational speed by measuring the frequency of a pulsed output signal. It also serves as a lock sensor that alerts users if the fan has stopped operation due to a loss of power, obstruction, etc. Being able to detect these problems as soon as possible is a major benefit to system operation and allows for timely shutdowns to protect temperature-sensitive components.

Auto-restart protection

Auto-restart protection detects when the fan motor is prevented from rotating and automatically cuts the drive current. This protects the fan-drive circuitry and notifies the fan controller of immediate problems due to the shutdown of the drive current.

Rotation detection/lock sensor

Used to detect if a fan motor is operating or stopped, rotation detection/lock sensor is a safeguard against problems at start-up or during operation.

Summary

When an application produces excess heat, dc fans are a common choice to keep components within their operating limits and to improve heat dissipation. While selecting and running a fan continuously after some basic thermal analysis is certainly an option, more advanced fan controls and protections can offer designers greater operational lifetime and efficiency. Same Sky carries a comprehensive portfolio of dc fans and blowers with a variety of sizes, airflows, speeds, and controls to make this process simple.

Disclaimer: The opinions, beliefs, and viewpoints expressed by the various authors and/or forum participants on this website do not necessarily reflect the opinions, beliefs, and viewpoints of DigiKey or official policies of DigiKey.