Types of Temperature Sensors

We use temperature sensors every day for temperature control in buildings, water temperature regulation, and to control refrigerators. Temperature sensors are also vital in many other applications such as consumer, medical, and industrial electronics.

Each application may have a different temperature sensing need. The differences include what is being measured (air, mass, or liquid), where it is being measured (inside or outside), and the range of temperature being measured. There are four types of temperature sensors that are most commonly used in modern-day electronics: thermocouples, RTDs (resistance temperature detectors), thermistors, and semiconductor based integrated circuits (IC).

This blog focuses on these four main types of temperature sensors, considerations for each type, advantages, and disadvantages.

Thermocouples

Thermocouples are the most commonly used type of temperature sensor. They are used in industrial, automotive, and consumer applications. Thermocouples are self-powered, require no excitation, can operate over a wide temperature range, and have quick response times.

Thermocouples are made by joining two dissimilar metal wires together. This causes a Seebeck Effect. The Seebeck Effect is a phenomenon in which a temperature difference of two dissimilar conductors produces a voltage difference between the two substances.1 It is this voltage difference that can be measured and used to calculate the temperature.

There are several types of thermocouples that are made from a variety of different material, which allows for different temperature ranges and different sensitivities. The different types are differentiated by designated letters. The most commonly used is the K type. Table 1 shows characteristics of a few common types of thermocouples.

Table 1. Thermocouple Types and Characteristics (adapted from “Tutorial 6500 Temperature Sensor Tutorial”)2

Table 1. Thermocouple Types and Characteristics (adapted from “Tutorial 6500 Temperature Sensor Tutorial”)2

Some disadvantages of thermocouples include the fact that measuring temperature can be challenging because of their small output voltage, which requires precise amplification, susceptibility to external noise over long wires, and cold junction. Cold junction is where thermocouple wires meet copper traces of the signal circuitry. This creates another Seebeck Effect which needs to be compensated for called cold junction compensation.

Maxim Integrated offers digital output thermocouples like the MAX31855 and MAX31856. These devices help with signal conditioning by incorporating a high-resolution analog to digital converter (ADC), low noise precision gain stage, and cold junction compensation sensor. These devices help designers of thermocouple circuits by offering accurate solutions for signal conditioning in a small package. They work with many of the popular types of thermocouple.

RTD (Resistance Temperature Detector)

As temperature changes, the resistance of any metal changes as well. This difference in resistance is what RTD temperature sensors are based on. An RTD is a resistor with well-defined resistance vs. temperature characteristics. Platinum is the most common and accurate material used to make RTDs.

Figure 1. Two, Three, and Four Wire RTDs2

Figure 1. Two, Three, and Four Wire RTDs2

Platinum RTDs are also referred to as PRTDs. They are often available with a 100 Ω and 1000 Ω resistance at 0°C. They are referred to as PT100 and PT1000 respectively.

Platinum RTDs are used because they offer a near linear response to temperature changes, they are stable and accurate, they provide repeatable responses, and they have a wide temperature range. RTDs are often used in precision applications because of their accuracy and repeatability.

RTD elements usually have higher thermal mass, and therefore respond slower to changes in temperature than thermocouples. Signal conditioning is important in RTDs. They also require an excitation current to flow through the RTD. If this current is known, the resistance can be calculated.

Configurations include two, three, and four wire options. The two-wire option is useful when lead length is short enough that resistance doesn’t significantly affect measurement accuracy. A three-wire adds an RTD probe that carries the excitation current. This provides a way to cancel wire resistance. Four-wire is the most accurate, as separate force and sense leads eliminate the effect of wire resistance. Figure 1 shows examples of two, three, and four wire RTD configurations. The MAX31865 offers a dedicated RTD signal conditioning circuit for each configuration with 15-bit resolution and offers a solution to accelerate designs for both PT100 and PT1000 RTDs.

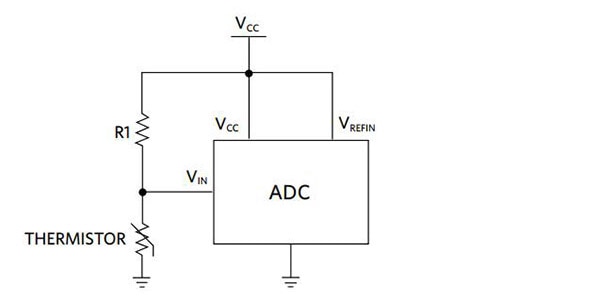

Figure 2. Typical Thermistor Interface2

Figure 2. Typical Thermistor Interface2

Thermistors

Thermistors are similar to RTDs in that temperature changes cause measurable resistance changes. Thermistors are usually made from a polymer or ceramic material. In most cases, thermistors are cheaper but are also less accurate than RTDs. Most thermistors are available in two wire configurations.

The NTC (Negative Temperature Coefficient) thermistor is the most commonly used thermistor for temperature measurement application. An NTC thermistor’s resistance decreases as the temperature increases. Thermistors have a non-linear temperature resistance relationship. This requires a significant correction to interpret the data correctly. A common approach of using a thermistor, shown in Figure 2, is where a thermistor and a fixed value resistor form a voltage divider with an output that is digitized by an ADC.

Semiconductor based ICs

Semiconductor based temperature sensor ICs come in two different types: local temperature sensor and remote digital temperature sensor. Local temperature sensors are ICs that measure their own die temperature by using the physical properties of a transistor. Remote digital temperature sensors measure the temperature of an external transistor.

Local temperature sensors can use either analog or digital outputs. Analog outputs can be either voltage or current while digital outputs can be seen in several formats such as I²C, SMBus, 1-Wire®, and Serial Peripheral Interface (SPI). Local temperature sensors sense the temperature on printed circuit boards or the ambient air around it. The MAX31875 is an extremely small local temperature sensor and can be used in multiple applications including battery powered applications.

Remote digital temperature sensors work like local temperature sensors by using the physical properties of a transistor. The difference is the transistor is located away from the sensor chip. Some microprocessors and FPGAs include a bipolar sensing transistor to measure die temperature of the target IC.

Summary

Thermocouples, RTDs, thermistors, and semiconductor based ICs are the main types of temperature sensors used today. Thermocouples are inexpensive, durable, and can measure a wide range of temperatures. RTDs offer a wide range of temperature measurements (although smaller than thermocouples) and provide accurate and repeatable measurements, but they are slower, require an excitation current, and require signal conditioning. Thermistors are durable and small, but they are less accurate than RTDs and require more data corrections to interpret temperature. Semiconductor based ICs are flexible to implantation and can come in extremely small packages, but they have a limited temperature range.

While there are other temperature sensor options available, the four choices discussed in this blog will give a solution for most designers to find a solution that can work for their application.

References:

1 – “What Is Seebeck Effect? - Definition from WhatIs.com.” SearchNetworking, TechTarget, searchnetworking.techtarget.com/definition/Seebeck-effect.

2 – R. Nicoletti, “Tutorial 6500 Temperature Sensor Tutorial,” Maxim Integrated. https://pdfserv.maximintegrated.com/en/an/Temp-Sensor-Tutorial.pdf

Have questions or comments? Continue the conversation on TechForum, Digi-Key's online community and technical resource.

Visit TechForum