Use an Online Tool for Custom Modifications of Standard Enclosures to Save Time and Reduce Cost

資料提供者:DigiKey 北美編輯群

2024-10-29

Electronic devices require enclosures to protect their internal components and users from shocks and burns. Enclosures, such as cases, boxes, fobs, chassis, and racks, are found around all electronics, from the most complex innovative technology to the simplest handheld toy. All enclosures have openings and various power, control, interface, or display modifications. Enclosures for initial prototypes are usually modified by hand as the device design develops. The next stage, pre-production or small lot production, requires custom modifications even if off-the-shelf enclosures are used.

Modifications done in-house can be inconvenient, distracting, and error prone. Using a third-party contractor is expensive, requires detailed documentation, and can incur scheduling delays. An alternative is to have designers modify a standard enclosure using a central online tool that offers custom modifications of standard enclosures from suppliers. Using standard enclosures generally costs less and requires less lead time than making a custom enclosure. It also guarantees repeatability for multiple orders over time.

This article introduces an online tool from DigiKey that enables requests for modifications to standard enclosures. It then outlines the steps required to implement a modification successfully.

DigiKey custom enclosures

To help with modifications of standard enclosures, DigiKey’s Custom Enclosure Configurator online software design tool simplifies the ordering process and reduces the chance of errors. It accommodates machining holes, slots, custom openings, tapping, threading, metal stamping, silk screening, direct printing, custom materials, and fastener installation, such as PEM nuts. The minimum order is 25 pieces.

For the configurator, DigiKey partners with enclosure suppliers (initially only Hammond Manufacturing upon the configurator’s release) that offer a broad range of standard enclosures and custom modifications based on one or more of their products. The suppliers are well suited to handle modifications to their standard products, as they have automated tools and years of experience in manufacturing. To order a modified enclosure, the following steps are required:

- The designer selects a commercial off-the-shelf enclosure to modify.

- The designer provides a drawing or sketch of the desired modifications based on the manufacturer's drawings. Product drawings for any of the partner’s enclosures are available on DigiKey.com or the manufacturer's website and can be used as a basis for modification drawings. The designer then adds to cart and checks out.

- The manufacturer will send an approval drawing through myDK within 5 business days for the designer to review and approve.

- The designer signs off if the drawing is approved, or sends in corrections or changes if needed.

- Once the drawing is approved, a first article sample is sent for approval within two weeks.

- After the sample is approved, the manufacturer will inform the designer of a production schedule and go to production on the order per the schedule.

Using the Custom Enclosure Configurator

It is helpful to use an example to go through each step involved in using the Custom Enclosure Configurator (Figure 1).

Figure 1: The Custom Enclosure Configurator provides a common interface to upload the desired modifications to any of the four enclosure suppliers. (Image source: DigiKey)

Figure 1: The Custom Enclosure Configurator provides a common interface to upload the desired modifications to any of the four enclosure suppliers. (Image source: DigiKey)

To begin the process, the designer selects the DigiKey part number for the product to be modified and uploads the drawings of the desired modifications (Figure 2). Once the part number is entered, the configurator will respond with the stocking status and a detailed description of the standard part.

Figure 2: Upon entering the base part number, the configurator reports the stocking status of the desired standard enclosure and displays a detailed product description. (Image source: DigiKey)

Figure 2: Upon entering the base part number, the configurator reports the stocking status of the desired standard enclosure and displays a detailed product description. (Image source: DigiKey)

The configurator prompts the designer to upload a file containing the details of the modification. The uploaded modification drawings can be in any of six formats: stp, step, pdf, dwg, zip, and dxf. The file size is limited to 10 megabits (Mbits) maximum. Per Figure 1, the tool suggests using a .zip file if there are multiple design files. On pressing the upload button, the configurator will prompt for the drawing and revision numbers.

Once the modification's drawing file is uploaded, the designer must select the units of measure, either millimeters (mm) or inches (in.), and then enter the surface(s) (top, bottom, side A through side F) to be affected by the modification.

The configurator prompts for the details of each modification identified in the modification drawing (Figure 3).

Figure 3: Each modification, whether it is a hole or a cutout, must be described by the affected surface, modification type, dimensions, and number. Additional attributes can also be selected. (Image source: DigiKey)

Figure 3: Each modification, whether it is a hole or a cutout, must be described by the affected surface, modification type, dimensions, and number. Additional attributes can also be selected. (Image source: DigiKey)

Modification details must include the affected surface, modification type (hole or cutout), dimensions, and number of identical modifications. Additional attributes such as countersinking, counterboring, tapping, and threading for holes, as well as pockets and chamfers for cutouts, can be flagged. Further modifications and surfaces can be added until all the changes are described.

After all the modifications are detailed, the configurator will prompt for an order quantity. It will then publish a quote indicating the available quantity, unit price, and price for the quantity ordered.

The final step cues the designer to review the quotation and place the order (Figure 4).

Figure 4: Shown is the final quotation summary before placing an order for the modified enclosure. (Image source: DigiKey)

Figure 4: Shown is the final quotation summary before placing an order for the modified enclosure. (Image source: DigiKey)

Obtaining drawings for standard enclosures

Modifying the manufacturer's standard drawings saves time in this process. DigiKey’s product page or the manufacturer’s website provides access to these drawings in PDF or STP file formats. Specific areas of the designs can be annotated to show the desired modifications (Figure 5).

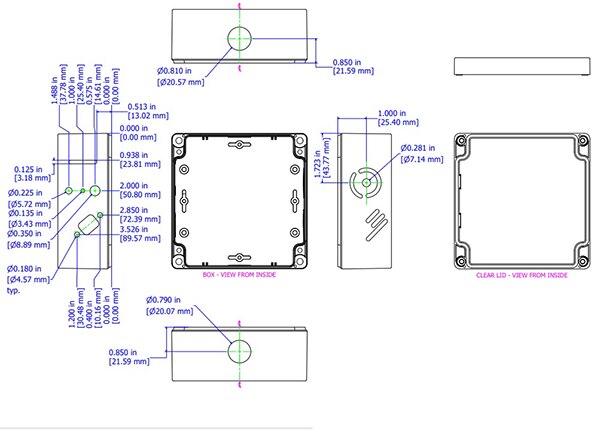

Figure 5: Shown is a drawing of a Hammond Manufacturing 1554N2GYCL enclosure available from DigiKey or the Hammond Manufacturing website. (Image source: Hammond Manufacturing)

Figure 5: Shown is a drawing of a Hammond Manufacturing 1554N2GYCL enclosure available from DigiKey or the Hammond Manufacturing website. (Image source: Hammond Manufacturing)

The appropriate views, abstracted from the supplied drawing, can be edited to show the desired modifications (Figure 6). Hole dimensions are described in the modification narrative in the configurator.

Figure 6: The front (right) and left-side (left) views are annotated to show the locations of the desired modifications. (Image source: Hammond Manufacturing)

Figure 6: The front (right) and left-side (left) views are annotated to show the locations of the desired modifications. (Image source: Hammond Manufacturing)

This sketch, plus the description of the holes in the configurator, allows the manufacturer to modify their standard product (Figure 7).

Figure 7: Shown is the modified standard enclosure based on the submitted sketch and the configurator description of the holesholes (cover not shown since it was not modified). (Image source: Hammond Manufacturing)

Figure 7: Shown is the modified standard enclosure based on the submitted sketch and the configurator description of the holesholes (cover not shown since it was not modified). (Image source: Hammond Manufacturing)

Conclusion

Modifications to standard enclosures done in-house can be inconvenient and error prone. DigiKey’s Custom Enclosure Configurator allows custom modifications to standard enclosures and benefits designers by providing a single interface to enclosure suppliers. This simplifies the ordering process, saves time, reduces cost, and allows repeatability.

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。