Practical LED Thermal Design

資料提供者:Convergence Promotions LLC

2011-11-22

Adding a simple thermal feedback protection circuit will give the designer peace of mind and guarantee a long LED lifetime under all operating conditions and temperatures.

In the last few years, the high-brightness light-emitting diode (LED) has developed enormously from a niche product as a high-priced designer spotlight to a useful general purpose light with system efficiencies of well over 100 Lumens/Watt and lifetimes exceeding 50,000 hours.

However, the introduction of high-power LED technology has pushed the issue of thermal management back to the forefront of lighting design. Like all semiconductors, LEDs must not become too hot otherwise their celebrated long lifetimes will be adversely affected. An LED rated at 50,000 hours with a junction temperature of 25°C will survive only half as long with a junction temperature of 125°C. At 175°C, the LED can be expected to survive only 100 hours.

Although the efficiency of a high-power LED is around six times better than a standard incandescent light bulb, a significant amount of the electrical energy flowing through the device is still converted into heat. Whereas the waste heat from an Edison bulb is mostly radiated away as infrared energy, the waste heat from an LED must be conducted away through a heat sink. Thermal management and the consideration of the effects of high environmental temperatures must thus be addressed right at the start of the design phase of a solid state lighting source.

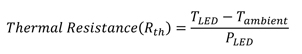

The factors affecting the effectiveness of a heat sink are the temperature difference between the heat source and ambient, the amount of heat generated (LED power), and the thermal resistance. The relationship of the factors can be expressed as an equation:

Equation 1:

Since the LED temperature is the most critical factor, this can be rewritten as:

Equation 1a:

Although Equation 1a looks deceptively simple, the term Thermal Resistance is made up of several other factors:

RTH(Total) = RTH(LED) + RTH(M) + RTH(HS), where RTH(LED) is the internal thermal resistance of the LED, RTH(M) is the thermal resistance of the mounting (e.g., thermal compound, gap pad, PCB, etc), and RTH(HS) is the thermal resistance of the heat sink.

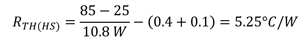

The maximum junction temperature and the thermal resistance of the LED are given in the manufacturer’s datasheet. For example, the CREE CXA2011 datasheet specifies an effective thermal resistance, junction to case, of 0.4°C/W and a maximum LED junction temperature of 150°C. However, to ensure a long life, a lower junction temperature of 85°C is recommended in the datasheet. If we assume an ambient temperature of 25°C, an LED current of 270 mA, and that the LED is assembled with thermal compound with a typical thermal resistance of 0.1°C/W, then Equation 1 gives:

If the LED was mounted onto an FR4 PCB instead of being directly attached to the heat sink, the result becomes:

The lower the thermal resistance, the larger the heat sink has to be. In this example, a black anodized aluminum two and one half inch square heat sink with half inch long fins would be acceptable in the first example but it would need to be 20 percent larger if the LED was mounted on a PCB instead of directly onto the heat sink.

Running the LED with a higher current requires an even larger heat sink with an even lower thermal resistance. For example, the CXA2011 can also run with a 700 mA LED current, but this then needs a heat sink with:

If the heat sink dimension stays two and one half inches square, the fins would need to be four inches long to reduce the thermal resistance below 1.5°C/W.

This simple example shows that the heat sink dimensions are very dependent on the operating conditions and construction of the LED lamp. The same LED may require a heat sink that is up to eight times larger if a different driving current is chosen.

If the physical size of the heat sink is limited by the aesthetic design of the lamp housing, then either the LED power or the thermal resistance of the heat sink has to be reduced. One way to reduce the thermal resistance of a heat sink without increasing its size is to increase its surface area by introducing more fins, however, if the fin density is too high, free air convection is impeded and this can be self-defeating. Alternatively, air can be forced through the heat sink using a fan or a pulsed air jet. Even a relatively low air velocity of 2 m/s (400 LFM) can halve the overall thermal resistance of a heat sink. The downside is the extra cost, noise, and the reliability overhead of a mechanical air mover to cool the LED lamp. Alternatives to forced convection are to use heat sinks made of better conducting materials (e.g., copper instead of aluminum) or to add liquid cooling (heat pipes) to transfer the heat away from the optical head. However, these solutions are also more costly and heavier than the standard extruded heat sink.

Certain applications demand thermal protection for the LED even if it has an adequate heat sink. As an example, a high power street light LEDs are off during the day. During the night when the LEDs are on and the ambient temperature is cold, a relatively compact heat sink can be used. But for a short period of time after nightfall, the LEDs are on but the LED housing is still warm from the day’s sun. During this time, the LEDs can easily exceed the maximum operating temperature. It is, therefore, always a good idea to include thermal protection to stop the LED from overheating. The simplest solution is a thermal trip or fuse that will break the current to the LED if it overheats, but this is a brute force solution and in many applications (e.g., the street light example, mentioned previously) it is unacceptable to be without illumination during a temporary over-temperature condition. A less drastic over-temperature protection method involves using thermal feedback to proportionately reduce the current drive to the LED if it begins to overheat. The reduction in LED brightness is then not so noticeable with the lamp always providing some light, and yet a long lifetime is guaranteed.

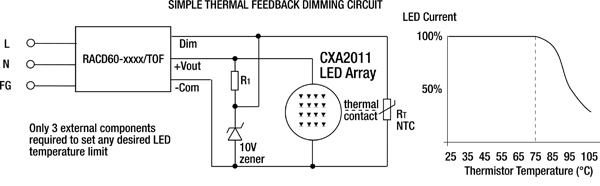

The RECOM datasheets and LED guide gives several examples of suitable thermal feedback circuits using simple, low-cost thermistor sensors.

In Figure 1, the RECOM RACD60-1050/TOF converter is paired with a CREE CXA2011 LED running at the limit of its drive current (1.05 amps or four times nominal). Despite the high drive current, the LED will still provide a long life if it has an adequate heat sink, but it is critical that the LED does not overheat. Fortunately, the RECOM constant current driver is fitted with a temperature feedback input. As illustrated in the circuit diagram, only three external components are needed: a resistor, a zener, and a thermistor. It is important that the temperature sensing circuit be as simple as possible in order to avoid impacting overall system reliability. All RECOM LED drivers come with a five year warranty, and any external components should be able to operate maintenance-free for at least the same period without failure.

The graph to the right of the circuit diagram shows how the LED current varies with temperature. Above a heat sink temperature of 75°C, the LED current is gradually throttled back to reduce the heat generated by the LED. The LED always stays on, but is nevertheless protected from overheating. R1 can be chosen to set any desired temperature limit within range. Normally, the thermal sensing element should be placed as close to the LED body as possible to provide the most accurate temperature monitoring, but this is not always easy without interfering with the mounting of the optics. In such cases, a lower temperature trip point, such as 65°C, can be used to compensate for the thermal lag between the sensor and LED temperatures.

In conclusion, these simple examples show how the lifetime of an LED lamp is closely interlinked with its mechanical and electrical design. To ensure long LED life, its heat sink must be adequately dimensioned and consideration given to how the surrounding airflow can dissipate the heat generated by the LED, using either passive or active air cooling. Assembling an LED with a correctly sized heat sink, but using the wrong thermal interface, can also easily result in overheating.

Finally, almost all high-power LED lamps will benefit from thermal protection. Even an “adequate” thermal design is based on certain assumptions about normal operating conditions. However, in practice things can still go wrong, such as the ambient temperature being higher than 25°C because the room’s air conditioner stopped working, or the airflow to the heat sink could be blocked by an incorrect installation or by dust. Adding a simple thermal feedback protection circuit will give the designer peace of mind and guarantee a long LED lifetime under all operating conditions and temperatures.

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。