使用 NTC 熱敏電阻監控 AI 資料中心溫度

資料提供者:DigiKey 北美編輯群

2025-09-04

隨著人工智慧 (AI) 需求的增強和功率密度的增加,資料中心面臨前所未有的熱管理挑戰。需要精準、即時的溫度監控,以達到最佳效能和效率,同時防止過熱。這些感測解決方案必須準確、靈敏、耐用,才可處理高敏感設備上快速變化的熱負荷。

本文探討現代人工智慧資料中心設計人員面臨的熱管理挑戰,探索各種冷卻系統,包括空調、浸沒式冷卻、熱導管解決方案。接著介紹 EPCOS (TDK) 的負溫度係數 (NTC) 熱敏電阻解決方案,並展示如何使用來因應這些挑戰。

為什麼人工智慧資料中心會有新的熱管理挑戰

圖形處理單元 (GPU) 和張量處理單元 (TPU) 等人工智慧硬體通常會比傳統中央處理單元 (CPU) 消耗更多的電量。因此,以人工智慧為中心的資料中心往往具有相當高的功率密度和集中的熱點,而這些熱點很難透過傳統的冷卻方法進行管理。

更糟的是,人工智慧工作負載常常變化很大,在密集訓練或推理操作期間,熱負載可能會遽增。如果沒有適當的熱管理,這種情況可能會導致效能節流、計劃外停機、硬體加速降額。

資料中心現正採用更先進的冷卻方法,回應這些新的需求。直接晶片冷卻是一種常見的方式。此技術將冷卻管、冷板、熱交換器直接放置在 CPU、GPU、記憶體等高功率組件上。浸沒式冷卻是另一種方式,將整個伺服器浸沒非導電液體中。

空調也有各種升級。例如,列間式與機架式冷卻設備以局部冷卻補足整體設施的空調,可即時回應熱點。

儘管這些冷卻系統的實際情況各不相同但都要求進行更廣且更即時的溫度監測。以直接晶片系統為例,每個目標晶片都需要已安裝散熱片的感測器,以確保維持溫度標準。冷卻劑的流入需要管道安裝的感測器進行監測,還需要在冷卻劑分配單元和熱交換器上安裝額外的感測器,用來驗證系統是否有效率地運作。

資料中心應用使用 NTC 熱敏電阻感測器的優勢

NTC 熱敏電阻非常適合滿足所有這些要求。顧名思義,隨著溫度升高,NTC 感測器的電阻會出現可預測的下降。NTC 熱敏電阻係透過封裝在保護性金屬或環氧樹脂外殼中的小型熱敏氧化陶瓷元件達到此效能。

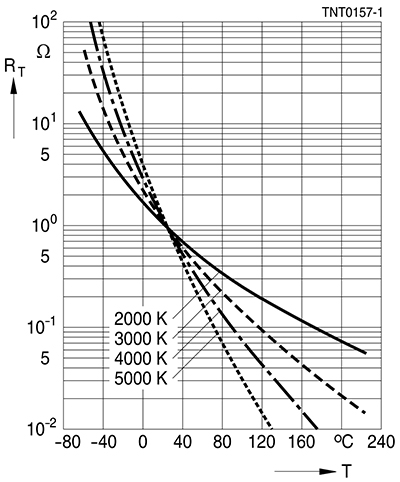

圖 1 顯示 25°C 時額定值為 2 至 5 kΩ 的熱敏電阻之典型溫度與電阻曲線。如圖所示,電阻值較高的熱敏電阻更適合高溫應用,因為更容易測量其電阻變化。

圖 1:25°C 時額定電阻值為 2 kΩ 至 5 kΩ 的熱敏電阻的典型溫度與電阻曲線。(圖片來源:EPCOS (TDK))

圖 1:25°C 時額定電阻值為 2 kΩ 至 5 kΩ 的熱敏電阻的典型溫度與電阻曲線。(圖片來源:EPCOS (TDK))

AI 資料中心使用 NTC 熱敏電阻的優勢:

- 高精密度和快速回應時間:NTC 熱敏電阻對輕微的溫度變化極為敏感,並且由於其熱質量較小,可以快速回應。這些因素使得 NTC 熱敏電阻正好符合 AI 資料中心快速波動的熱需求。

- 耐用性和穩定性:NTC 熱敏電阻由耐用的材料製成,具有出色的長期可靠性,並且隨時間推移的電阻漂移最小。這種穩定效能大幅減少維護要求,並且降低意外停機的風險。

- 體積小巧、安裝靈活:其體積小巧,可輕鬆整合資料中心擁擠且空間寶貴的環境中。具有多種外型尺寸,可滿足各種 AI 資料中心冷卻系統的需求。

EPCOS 系列 NTC 熱敏電阻展現這些優勢。此系列包括用於監控散熱片和管道、浸沒式冷卻系統、空氣處理單元的解決方案。

使用安裝散熱片的 NTC 熱敏電阻,監控高功率組件

GPU 和 TPU 等高功率處理器需要密切的熱監控,以保持效能並防止過熱。B57703M0103G040 (圖 2) 設計用於直接附著至散熱片,非常適合此作業。此螺絲固定感測器將 NTC 熱敏電阻封裝在帶有突出環形接片的金屬標籤盒中。

圖 2:B57703M0103G040 環形接片熱敏電阻可對高功率處理器的散熱片進行精準的溫度監控。(圖片來源:EPCOS (TDK))

圖 2:B57703M0103G040 環形接片熱敏電阻可對高功率處理器的散熱片進行精準的溫度監控。(圖片來源:EPCOS (TDK))

螺絲固定感測器的設計既方便又重要,可確保良好的熱耦合及與散熱片表面一致的接觸力,並在負載快速變化時,降低熱阻並提高測量精密度。

此感測器在 +70°C 下經過超過 10,000 小時的長期穩定性測試,支援在 AI 資料中心工作負載常見的高溫條件中使用。在 +25°C 時,額定值為 10 kΩ,測量更高的工作溫度時可提供可靠的基礎,為溫度控制系統提供準確的回饋。

使用 NTC 熱敏電阻監測液體冷卻管

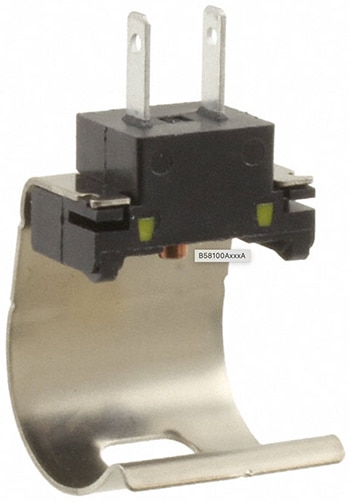

液體冷卻系統需持續供應具有適當溫度的冷卻劑。B58100A0506A000 (圖 3) 是 10 kΩ NTC 熱敏電阻,設計用於快速安裝在管道上,是監控冷卻劑供應管道的理想選擇。此模製組件可直接夾在直徑 18 mm至 19 mm 的管道上,並有其他尺寸可供不同安裝使用。內建觸點接片,可直接連接監控設備。

圖 3:B58100A0506A000 夾式熱敏電阻,用於測量液體冷卻系統中的冷卻劑溫度。(圖片來源:EPCOS (TDK))

圖 3:B58100A0506A000 夾式熱敏電阻,用於測量液體冷卻系統中的冷卻劑溫度。(圖片來源:EPCOS (TDK))

監測外部管道溫度的方式準確且容易維護,無需將感測器直接浸沒液體中,即可追蹤冷卻劑效果。這種方法能簡化安裝,降低洩漏風險,並且在有需要時可快速更換感測器。

熱時間常數是溫度感測器的一個關鍵效能參數,也稱為熱響應時間,反映 NTC 熱敏電阻的電阻值回應外部溫度波動的速度。此參數受感測器的設計、安裝配置、周圍環境的影響。

例如,B58100A0506A000 採用銅外罩將感測器與管道進行熱耦合,以達到小於 5 秒的熱時間常數 (在管道上測量)。此快速反應時間有助於確保可靠的冷卻劑供應。

使用 NTC 熱敏電阻監測冷卻劑分配系統

除了監控熱源和冷卻劑供應管路外,液體冷卻系統還需要在冷卻劑分配單元、熱交換器,以及其他中央組件進行溫度感測。B57800K0103A001(圖 4) 非常適合擔任這個角色。其圓柱形銅製外殼具有優異的導熱性,能夠精準測量系統關鍵點的流體溫度。

圖 4:B57800K0103A001 圓柱形探針熱敏電阻,用於監測分配系統中的冷卻劑溫度。(圖片來源:EPCOS (TDK))

圖 4:B57800K0103A001 圓柱形探針熱敏電阻,用於監測分配系統中的冷卻劑溫度。(圖片來源:EPCOS (TDK))

此感測器為 10 kΩ ,工作溫度為 +150°C,可以放置在熱側而不會有過熱風險。在水中的熱時間常數約為 8 秒,使其能以夠快的速度追蹤冷卻劑溫度的變化,執行系統級控制和保護。

這些組件的出入口都有部署感測器,讓操作人員追蹤熱交換器或分配迴路之間的溫差。若有明顯的偏差,可能表示有冷卻劑流量減少、部分堵塞,或熱交換器表面污染等問題,有助於在系統效能受到影響前進行預防性維護。

使用 NTC 熱敏電阻監測浸沒式冷卻系統

浸沒式冷卻系統將伺服器浸沒非導電液體 (如介電油) 中,感測器需要能夠承受潛在腐蝕性。B57504K0103A009 (圖 5) 是專為此類環境設計的 10 kΩ 感測器。其不鏽鋼外殼在輕微腐蝕環境下耐用,同時確保與感測元件進行有效熱耦合。

圖 5:B57504K0103A009 不鏽鋼探針熱敏電阻,用於監測浸沒式冷卻系統中的冷卻劑溫度。(圖片來源:EPCOS (TDK))

圖 5:B57504K0103A009 不鏽鋼探針熱敏電阻,用於監測浸沒式冷卻系統中的冷卻劑溫度。(圖片來源:EPCOS (TDK))

此感測器在水中的熱時間常數小於 2 秒,能夠精準追蹤浸沒槽內的溫度變化。

使用 NTC 熱敏電阻監測空調

最後,考慮使用 B57500M0103A005 (圖 6)。這款元件為 10 kΩ,納入簡單的環氧樹脂中,達到緊湊的外型尺寸,並配有 470 mm 引線,可提供靈活的佈線選擇。例如,其具有小尺寸和長引線,因此可安裝在靠近蒸發器盤管或氣流通道內,在此處快速偵測溫度變化有助於保持穩定的環境控制。

圖 6:B57500M0103A005 環氧樹脂封裝熱敏電阻可用來監控空調系統。(圖片來源:EPCOS (TDK))

圖 6:B57500M0103A005 環氧樹脂封裝熱敏電阻可用來監控空調系統。(圖片來源:EPCOS (TDK))

此外,此感測器已經過驗證,可耐受交流系統中常見的振動、快速溫度循環和其他危害,且不會造成實體損壞或對測量準確度有重大影響。

結論

人工智慧工作負載促使資料中心內部迫切需要分散式溫度監控。EPCOS (TDK) 系列 NTC 熱敏電阻提供散熱片、冷卻劑管道、浸沒式浴槽、空氣處理單元等選項,可在嚴苛環境下支援可靠、靈敏的操作。

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。