訊號和電源連接器與機器人和其他高密度工業應用的匹配

資料提供者:DigiKey 北美編輯群

2025-08-13

智慧工廠透過分散式智慧和控制,並運用模組化機器人機器概念更加自動化。這種控制功能需要透過電線和纜線的連接進行實體配置,以確保可靠、安全的連接器與現代工廠的環境要求相符。此類連接器必須具有低電阻、足夠的觸點表面以處理其額定電流,以及強大的鎖定機制來抵抗振動和衝擊。此外,還必須容易組裝和修改,以便快速更新和更改。

本文概述工業機器人和工廠自動化的連接需求。接著介紹 TE Connectivity AMP 的一系列連接器,並展示如何運用其功能支援這些應用的電源、訊號、可靠性、安全需求。

什麼是智慧工廠?

智慧工廠是一種整合設施,使用數位互連的機器、機器人、本機感測器進行控制、即時資料收集、分析、決策 (圖 1)。此類工廠越來越分散和模組化,可以輕鬆地重新配置,以滿足不斷變化的生產需求。模組化組織有利於進行本機控制和使用小型機器,以提高生產的靈活性。

圖 1:智慧工廠採用連線的機器、機器人、互連感測器,確保高效率運作。(圖片來源:TE Connectivity AMP)

圖 1:智慧工廠採用連線的機器、機器人、互連感測器,確保高效率運作。(圖片來源:TE Connectivity AMP)

這些設施使用模組化工作站,配備獨立或協作機器人 (cobot) 。可移動型機器人(如自動導引車 (AGV) 或自主移動機器人 (AMR)) 會在工作站之間來回移動產品。相較於固定機器人,AMR 和 AGV 的優勢在於具備高移動性,可以在工作站之間旋轉和平移。將 AGV、AMR、協作機器人協同工作,生產線可以在獨立的單元內執行不同的任務。機器人可以在工作站之間移動或根據需求重新指派,提高整體效率。這些工作站通常位於惡劣的環境中,因此設計人員必須考慮到機器人和其他自動化機器可能暴露在高溫、潮濕、灰塵、腐蝕性化學物質以及衝擊和振動中。

感測器監控所有操作。根據設計,感測器可以有線或無線。無線感測器通常透過工業物聯網 (IIoT) 連接。可移動型機器人也使用 IIoT 進行監控和控制。

產業趨勢與電子系統有相同的典型特徵,均朝向更小的機器人、機器、感測器和控制器發展。體積小、重量輕代表功率需求更低、可用佔地面積更大,進而提高產量。此外,也可採用更小的印刷電路板 (PCB),此類電路板需要具有高容積效率的組件。

靈活可靠的電源和訊號連接器

無論是線對線、線對板或線對面板連接器,都必須可靠地承載電源和控制訊號。連接器越小,間距就越近,導體間隙也越細。

在定義上,模組化設計具備靈活性;因此,連接器解決方案必須像自動化系統一樣具有適應性。為了滿足靈活需求,連接器的設計必須確保具備安全、方便的鎖定機制,以防止在組裝過程中的錯誤配接,以及因衝擊和振動而導致的意外拔出。

TE Connectivity AMP 的 Dynamic 系列連接器可滿足需要高密度的工業訊號和電源電路之需求。此連接器透過多個連接器並聯,滿足這些要求,可處理 2.6 至 100 A 的電流和 125 至 1000 V 的電壓。依據電流和電壓額定值,這些連接器可提供高密度互連,導體間距為 1.8 至 24.5 mm。

Mini 系列是最小巧的 Dynamic 連接器。此系列適用於線對板應用,觸點間距為 1.8 mm,提供 12、16、20 個腳位。接受 22 至 26 AWG 尺寸的電線,額定值為 3 A 時可處理 250 VAC。

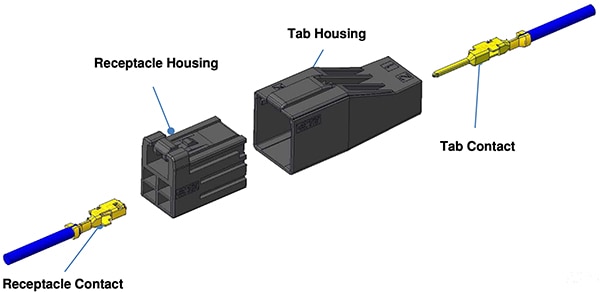

以 1-2834461-2 (圖 2,上) 為例,這是一款 12 觸點插座外罩,觸點排列成雙排,兩排間距為 2.75 mm。此連接器長 19.3 mm、寬 15.7 mm、高 8.35 mm。

圖 2:12 引腳 Dynamic Mini 線對板插座 (上) 和排針座 (下) 的元件。(圖片來源:TE Connectivity AMP)

圖 2:12 引腳 Dynamic Mini 線對板插座 (上) 和排針座 (下) 的元件。(圖片來源:TE Connectivity AMP)

此插座外罩裝有 TE Connectivity AMP 2834464-5 插座接點。這些是鍍錫銅合金壓接端子,接受 26 AWG 電線。其額定工作電壓為 250 VAC 或 125 VDC,可處理 3 A 電流。每個觸點都使用鎖矛,將其固定於外罩。此外,此外罩還配有嵌入式輔助鎖,為觸點端子的鎖定機制提供額外安全性。

此插座與 1-2834465-2 12 引腳表面黏著排針座配接 (圖 2,下)。此排針座長 19.3 mm、寬 12.3 mm、高僅 8.7 mm。此排針座包括全覆蓋式方形橫截面鍍錫觸點引腳。

此連接器對採用鍵控設計,可防止錯誤插入,並配有鎖定閂鎖,在插座和排針座完全嚙合時,提供聽覺和觸覺回饋。閂鎖位於連接器頂端下方,以防止意外解鎖。側栓為排針座提供機械支撐。

Mini 系列連接器尺寸更小、可靠性更高,不僅滿足工業環境的要求,也滿足機器人、汽車等對抗振效能要求更高的其他應用的要求。

更高電流適用的連接器

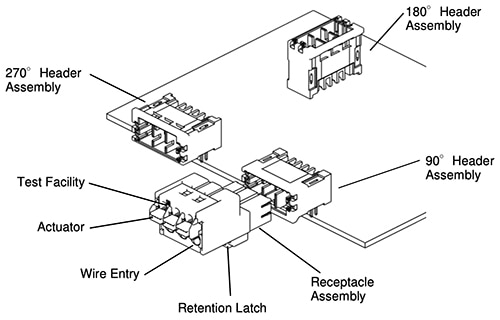

連接器尺寸增加以滿足處理更高電流的需求。Dynamic D1000 Slim 連接器 (圖 3) 可處理更高電流範圍。例如,1-2366600-4 是兩排四腳位插頭外罩,觸點間距為 2.7 mm,排距為 2 mm。此插頭外罩與 1-2366515-4 插座外罩配接,進行線對線直列連接。D1000 與 Mini 系列連接器一樣,包含一個提供聽覺和觸覺回饋的閂鎖,以確保正確接合。提供插座和接片壓接觸點,可納入 22 至 30 AWG 尺寸的電線。D1000 連接器的額定最大電流為 8.3 A,視所選的線規而定。

圖 3:四腳位 D1000 Slim 線對線連接器的組裝圖。(圖片來源:TE Connectivity AMP)

圖 3:四腳位 D1000 Slim 線對線連接器的組裝圖。(圖片來源:TE Connectivity AMP)

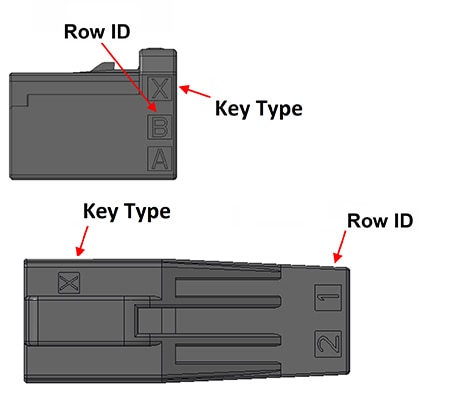

其外罩提供水平或垂直鍵控,確保達到正確匹配。配對連接器組長 21.5 mm、寬 7.2 mm、高 8.9 mm。外罩上清晰標識排標識和鍵類型,可大大減少配置和接線錯誤 (圖 4)。

圖 4:D1000 Slim 外罩使用的排標識和鍵方向標記。(圖片來源:TE Connectivity AMP)

圖 4:D1000 Slim 外罩使用的排標識和鍵方向標記。(圖片來源:TE Connectivity AMP)

現場安裝

除了壓接觸點版本外,Dynamic 系列還包括多種連接器類型。另提供籠式或彈簧夾連接器,如 D-2970 系列 (圖 5)。彈簧夾連接器與壓接觸點連接器不同,較容易進行現場安裝或修改。將電線末端的絕緣層移除,插入連接器主體的電線入口連接埠,其彈簧夾與電線嚙合並合起,將其鎖定到位。按壓釋放按鈕,就能移除插入的電線。無需任何工具即可對連接器接線或拆線。

圖 5:線對板 D-2970 系列連接器無需工具即可接線,只需將剝好的電線插入電線入口即可。(圖片來源:TE Connectivity AMP)

圖 5:線對板 D-2970 系列連接器無需工具即可接線,只需將剝好的電線插入電線入口即可。(圖片來源:TE Connectivity AMP)

D-2970 系列的範例包括 2336491-4 四觸點單排排針座,可與 2336488-4 四腳位插座連接器配接,用於線對 PC 板組裝。此連接器對具有 5 mm 觸點間距,可容納 14 至 24 AWG 的電線,最高可處理 14 A 的電流,依據所選的線規而定。其額定電壓高達 300 V。

排針座寬 22 mm、深 34 mm、高 18.7 mm;插座寬 24.9 mm、深 14.8 mm、高 9.8 mm。

結論

用於機器人和工廠自動化的工業電源和訊號連接器必須仔細選擇,以確保取得可靠性、安全性、靈活性、訊號完整性。TE Connectivity AMP 的 Dynamic 系列連接器為設計人員提供豐富的引腳配置,強調高密度、鍵控外罩、清晰標記、鎖定能力、抗衝擊和抗振動,以及緊湊尺寸等特點。

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。