設計具備安全性且可維護的控制面板

資料提供者:DigiKey 北美編輯群

2025-06-04

工業自動化系統越來越複雜,控制面板的設計也需要更周全。如果不仔細考量人體工學,面板可能會雜亂無章,導致安全隱患、操作錯誤、延誤長期維護。要避免這些問題,設計人員需優先考慮人為因素,以確保面板可直覺操作且容易維護。

本文簡要概述與控制面板設計相關的挑戰。接著介紹 Panduit 的一套解決方案,說明如何相輔相成,建立更安全、更容易維護的控制面板,支援可靠的系統效能。

為什麼需重視纜線管理系統

控制面板在許多使用上的挑戰源於接線。常見的問題包括組件標示不清、佈線纏繞,以及關鍵區域難以觸及。

採用綜合纜線管理系統 (如 Panduit 提供的系統),可明確地解決這些問題。這些系統涵蓋各種可搭配運用的組件,包括標籤、佈線管、紮線帶、纜線安裝座,提供乾淨、安全的纜線管理,協助順利安裝和可靠運作。

使用佈線管整理和保護纜線

佈線管是協助控制面板整理佈線的基礎元件。佈線管提供結構化的纜線佈線和保護方法,有助於技術人員瞭解整體纜線分佈,並且可減少意外斷開。

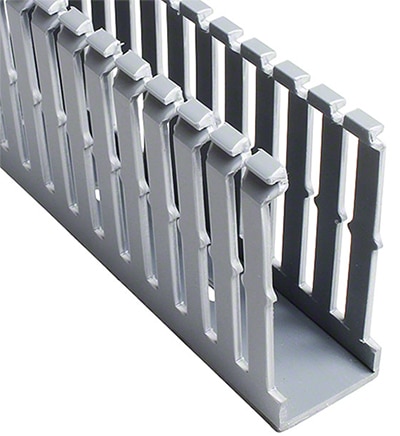

以 Panduct Type F 系列佈線管說明其優點。本產品線採用「指槽」設計,沿著管道側壁交替實心部分 (指片) 和開放空間 (插槽)。插槽間距為窄小的 0.5 in,以便整齊佈設高密度端子台和緊密的組件。

此系列的插槽僅 0.2 in 寬,可緊密貼合向外的纜線,並且在指片間有一個突起處,用於固定電線。此雙重固定設計可減少對紮線帶和線槽蓋板的需求,簡化安裝和維護。若需要更大的纜線出口,可利用刻痕輕鬆移除指片或更多側壁。

此系列包含從 1.25 x 3.13 in 的 F1X3LG6 (圖 1) 至 4.25 x 5.1 in 的 F4X5LG6。提供各種尺寸選項,能因應緊湊型控制面板有限的空間,以及符合大型安裝中管理複雜線束之需求。

圖 1:Type F 系列佈線管中的 F1X3LG6,尺寸為 1.25 x 3.13 in。(圖片來源:Panduit)

圖 1:Type F 系列佈線管中的 F1X3LG6,尺寸為 1.25 x 3.13 in。(圖片來源:Panduit)

搭配蓋板,如 C4LG6 (圖 2),寬 4 in,有助於隱藏和保護較少接觸的纜線,降低意外干擾的風險。

圖 2:Type F 系列佈線管的 C4LG6 蓋板寬度為 4 in。(圖片來源:Panduit)

圖 2:Type F 系列佈線管的 C4LG6 蓋板寬度為 4 in。(圖片來源:Panduit)

所有 Panduct 的 Type F 佈線管均由無鉛 PVC 製成,並符合 RoHS、UL、CE、CSA 標準。其耐燃等級達 UL94V-0,為整體系列產品提供一致的安全性和效能。

使用紮線帶固定和整理纜線束

纜線捆綁有助於維持安全、直覺的控制面板佈局。適當的捆綁不僅可以提高可見度,還可以減少意外斷開、磨損、機械應變的風險。

選擇紮線帶時,考量因素包含環境暴露、抗拉強度要求,以及與其他面板組件的材料相容性等。遵守業界標準 (如纜線管理系統的 UL 62275) 對於確保長期可靠性和安全性也有關鍵作用。

Panduit 提供多款紮線帶,可滿足各種需求。Pan-Ty PLT 系列和Dome-Top Barb Ty BT 系列,顯示可用的不同選項。這兩個系列均提供多種尺寸和材料,適應不同的線束直徑和暴露的環境。主要的區別在於其鎖定機制。

Pan-Ty 紮線帶採用一體成型塑膠鎖定頭,許多安裝人員都熟悉此機制。以 PLT2I-M (圖 3) 為例,PLT2I-M 專為室內所設計,由尼龍 6.6 製成,具有彎曲的尖端,容易操作及快速安裝。支援的線束直徑最大達 2.0 in,並且適合緊湊且空間受限的控制面板佈局。

圖 3:PLT2I-M 具有一體成型塑膠鎖頭。(圖片來源:Panduit)

圖 3:PLT2I-M 具有一體成型塑膠鎖頭。(圖片來源:Panduit)

若應用需要更高強度,可採用 Dome-Top 紮線帶。這些紮線帶,包括 BT4S-M0 (圖 4),配有不鏽鋼鎖鉤,可不受限地進行調節,並具有卓越的固定能力。BT4S-M0 由抗紫外線和耐天候的黑色尼龍 6.6 製成,適合戶外環境。可容納直徑最大 4.0 in 的線束,採用光滑的圓邊保護纜線,且可提高安裝人員的舒適度。

圖 4:BT4S-M0 紮線帶配有不鏽鋼鎖定倒鉤。(圖片來源:Panduit)

圖 4:BT4S-M0 紮線帶配有不鏽鋼鎖定倒鉤。(圖片來源:Panduit)

為了簡化安裝並確保較大紮線帶的張力一致,Panduit 建議使用 GTH-E 紮線槍 (圖 5)。紮線槍可將紮線帶平整切割,消除鋒利邊緣,避免損壞相鄰纜線束,進而提高安裝品質。此外,提供人體工學,有助於將工人的疲勞降至最低並減少勞動時間。

圖 5:GTH-E 紮線槍可簡化安裝過程。(圖片來源:Panduit)

圖 5:GTH-E 紮線槍可簡化安裝過程。(圖片來源:Panduit)

使用紮帶安裝座固定線束

纜線支架為紮線帶提供安全的錨點,確保線束牢固地固定到位。在纜線需要離開管道並延伸至最終連接點時尤其實用,有助於保持乾淨的佈局並提供長期可靠性。

選擇正確的安裝座需評估面板環境、預期機械應力,以及安裝偏好。背膠安裝座非常適合改造或空間受限且無法鑽孔的區域,而螺絲安裝座則具有出色的承載能力和抗振性。

Panduit 提供各種尺寸、材料和固定方法的紮線帶安裝座,可滿足各種機械和環境要求。ABMM-AC (圖 6) 是其中一款代表性品項。ABMM-AC 由 ABS 塑膠製成,具有四向入口,可簡化紮線帶的定位和安裝。此安裝座專為較輕的負載所設計,並使用橡膠基底黏合劑連接,因此非常適合不可鑽孔或以機械固定的應用。

圖 6:ABMM-AC 紮線帶安裝座有四個開口,可靈活安裝。(圖片來源:Panduit)

圖 6:ABMM-AC 紮線帶安裝座有四個開口,可靈活安裝。(圖片來源:Panduit)

針對較大負載需求或需要最高穩定性的區域,設計人員可以選擇以機械固定的替代方案,例如 TM3S10-C (圖 7)。此安裝座使用 #10 (M5) 螺絲固定,由耐用的尼龍 6.6 製成,適用於更高要求的環境。

圖 7:TM3S10-C 紮線帶安裝座可用螺絲固定到位,達到堅固的安裝。(圖片來源:Panduit)

圖 7:TM3S10-C 紮線帶安裝座可用螺絲固定到位,達到堅固的安裝。(圖片來源:Panduit)

透過清楚的標籤解決安全和合規問題

清楚、耐用的標籤有助於確保控制面板的安全操作和高效率維護。正確識別電線和組件可降低錯誤風險、遵守業界標準,並加速維護時排除故障。

在各產業中,清楚的標籤不僅是最佳實務,也是監管要求。NFPA 79 等標準要求正確識別控制電路,以防止事故發生並確保安全操作,在此強調標籤耐用、清楚的必要性。

Panduit 提供一系列專為因應控制面板環境的獨特挑戰所設計的標籤解決方案。Turn-Tell 標籤系統 (圖 8) 是一個多功能的選擇,其中包括 R100X150V1T 。這些標籤設計為圍繞電線和纜線,允許轉動以方便看見標示,亦適用於密集或空間受限的佈局中。自層壓設計提供更高耐用性,可保護印刷資訊免受磨損、潮濕以及其他環境危害。

圖 8:Turn-Tell 標籤圍繞纜線旋轉,能更容易看見標示。(圖片來源:Panduit)

圖 8:Turn-Tell 標籤圍繞纜線旋轉,能更容易看見標示。(圖片來源:Panduit)

針對需要標籤位置固定的應用,S100X150VATY (圖 9) 熱轉印標籤是可靠的替代方案。此標籤採用自層壓設計,其白色可列印區域和環繞纜線的透明尾部,可密封和保護列印區域。S100X150VATY 的尺寸為 1.0 x 1.5 in,非常適合中等直徑的電線和纜線。其乙烯基材料具有強大的耐油、耐水、耐溫和溶劑的能力,即使在嚴峻的工業環境下,也能確保重要的標籤長期清晰易讀。

圖 9:S100X150VATY 熱轉印標籤由耐用的乙烯基製成,可以耐受嚴峻的環境條件。(圖片來源:Panduit)

圖 9:S100X150VATY 熱轉印標籤由耐用的乙烯基製成,可以耐受嚴峻的環境條件。(圖片來源:Panduit)

Panduit 亦提供全面的熱轉印列印解決方案 TDP43ME-KIT (圖 10),可簡化標籤的製造和貼標。此套件包括 TDP43ME 列印機、Panduit Easy-Mark Plus 標籤軟體、黑色混合色帶 (RMEH4BL),以及捲帶架、保護盒和 S100X150VATY 標籤起始卷等基本配件。此系統可讓技術人員根據需求製造高品質、耐用的標籤,確保整個貼標過程的一致性和準確性。

圖 10:Panduit TDP43ME 列印機套件提供完整的標籤解決方案,包括軟體、色帶和配件。(圖片來源:Panduit)

圖 10:Panduit TDP43ME 列印機套件提供完整的標籤解決方案,包括軟體、色帶和配件。(圖片來源:Panduit)

結論

以使用者為中心的設計對於現代控制面板的安全性和維護性有關鍵的作用。整合式 Panduit 系統可立即滿足這些需求,包括高可見度標籤、多功能佈線管、安全紮線帶和安裝座,以及符合人體工學的安裝工具。實作這些解決方案不僅可以讓控制面板更安全、更可靠,而且也更容易和快速進行安裝和維護。

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。