降壓穩壓器能克服 LDO 的電源與熱能缺點

資料提供者:DigiKey 北美編輯群

2025-09-23

設計人員經常傾向使用低壓降線性穩壓器 (LDO),利用 4 至 20 mA 電流迴路設計來供電給工業感測與 IoT 系統。但 LDO 對於注重功耗與空間有限的應用而言,效率越來越不足。這就是設計人員應考慮轉用降壓穩壓器 (亦稱為降壓轉換器) 的原因,尤其是在極為講究能源效率、熱效能和延長電池續航力的應用。

4 至 20 mA 的電流迴路是穩健且可靠的作法,可將感測器的測量結果傳輸至可編程邏輯控制器 (PLC),以及將 PLC 的控制輸出傳輸到流程調變裝置。此系統使用雙絞線纜線,確保訊號在遠距離傳輸中保持準確且抗雜訊,因此適合各種工業環境使用。無論電線長度如何,穩定的電流對工廠、實驗室及遠端監測應用來說皆是標準要求。

評估 LDO 與切換式穩壓器在電流迴路中的取捨,有助於達到更智慧、更永續的設計。

LDO 在一些利基型應用中仍有其價值,因為一直以來都可提供超低雜訊、簡化物料清單,甚至是在極少電壓餘裕下達到穩壓的優點。然而,其本質上效率較低,因為會將輸入與輸出之間的電壓差異以熱能形式耗散。這些浪費的能量會導致應用中的熱負載增加,而且會大幅縮短可攜式或遠端應用的電池續航力。

若重視效率、熱效能或電池續航時間,同步降壓應該較好的選擇。有款現代化的同步降壓轉換器即使在毫安培負載下也能達到 85% 至 95% 的效率,不僅能大幅降低發熱,現在更可提供低微安培範圍的靜態電流。雖然 LDO 會將多餘的電壓以熱能形式耗散,但降壓穩壓器能有效地將多餘電壓轉換成可用電流,因此能讓更多耗電功能運作,而不會過熱或浪費能量。

對任何具有超過幾伏特輸入餘裕、需要熱效率或必須以有限電源 (如電池供電式感測器) 長時間運作的 4 至 20 mA 迴路而言,降壓穩壓器憑藉這些特性,而成為首選解決方案。

如果一款設計的電源電壓比電流迴路的發射器需求高出約 6 V,且電路板上有空間可放置小型電感和輸出電容,高效率的同步降壓穩壓器往往會是最佳選擇。不僅能有效降低電壓、減少廢熱,更可確保足夠電流,以便在 4 至 20 mA 迴路中供電給額外功能。因此非常適合用於現代傳輸器,可滿足其在工業環境中對可靠度與能源效率的需求。

降壓穩壓器的熱優勢可在高電流、高溫的工業模組中,大幅降低對散熱片的需求。即使是 5 µA 的降壓轉換器,其效率仍高於浪費大量電池電壓當作廢熱的 LDO。

迴路的驅動

4 至 20 mA 電流迴路是現場感測器與控制系統之間傳遞資訊的最常見方式之一。訊號可以代表溫度、壓力、流量,甚至是驅使閥門移動的命令。不止簡單可靠,更適合遠距離使用。

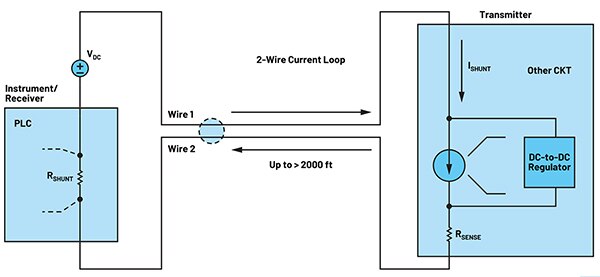

一個電流迴路 (圖 1) 可以將來自儀器 (如溫度或壓力感測器) 的測量訊號或控制訊號,傳送到可驅動或調整機構 (如閥門定位器) 的裝置。

圖 1:此 4 至 20 mA 電流迴路示意圖可說明如何在工業自動化、感測器系統及製程控制應用中,以電流取代電壓來傳輸類比訊號。(圖片來源:Analog Devices, Inc.)

圖 1:此 4 至 20 mA 電流迴路示意圖可說明如何在工業自動化、感測器系統及製程控制應用中,以電流取代電壓來傳輸類比訊號。(圖片來源:Analog Devices, Inc.)

一個電流迴路包含四個要素:

- DC 電源供應器:可以是 9 V、12 V、24 V 或更高,視配置而定。電源必須提供略高的電壓,至少比所有迴路元件 (發射器、接收器、配線) 在電流流動時所產生壓降電壓還高出約 10%。本機穩壓器接著會將電壓降低,以供電給感測器和電子元件。

- 感測器端的發射器會傳遞代表實體世界的電氣訊號:感測器會產生與溫度、壓力、距離或其他物理測量項目有關的原始訊號。如果是類比電壓,發射器的電壓對電流轉換器會將其轉換成介於 4 mA 至 20 mA 之間的比例式電流。如果是數位感測器,輸出會透過 DAC 轉回成類比電流。發射器有自己的電源供應器,例如 LDO 或降壓穩壓器。

- 控制端的接收器:接收器會讀取 4 至 20 mA 訊號,並將其轉換成控制系統可測量、顯示或操作的電壓。

- 迴路線路可將電源、發射器與接收器串聯在一起:迴路可延伸數千英尺。在雙線系統中,同樣的兩條線同時傳輸電力和訊號電流。四線系統則使用獨立對線分別傳輸電力與訊號。

電流迴路的零件必須準確、高能效且可靠,即使在溫度可從 -40°C 變動至 +105°C 的嚴峻工業環境中也要維持。此外,還必須支援必要的安全和系統層級功能,以確保迴路安全可靠。

克服 LDO 限制

線性穩壓器使用簡便且低雜訊,但會將多餘的能量以廢熱形式耗散,且可用電流有硬性上限。隨著設計人員在發射器上新增更多功能,例如診斷、數位介面或本機智慧能力,對電力的需求也跟著增加,可能會超過簡單 LDO 能提供的程度。更好的選擇是採用效率更高的切換式穩壓器,例如 Analog Devices, Inc. 的 LT8618 系列。

LT8618 是小巧但強大的降壓轉換器,專為嚴苛環境設計,包括工業、汽車以及其他採用無法預測電源的應用。特別適用於 4 至 20 mA 電流迴路系統,可提供超低靜態電流、高效率、3.4 V 至 60 V 的寬廣輸入範圍,因此可連續運作,並具有最高達 65 V 的瞬態能力。

LT8618 系列提供多樣化的降壓穩壓器,適用於各種工業及迴路供電式應用。例如:

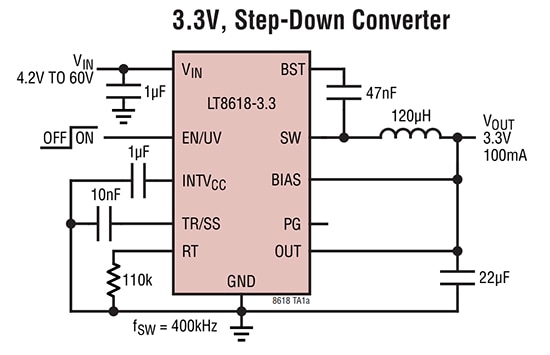

- LT8618EDDB-3.3#TRPBF (圖 2 中的線路圖) 就提供固定的 3.3 V 輸出,非常適合需要穩定且明確電壓的設計,以因應工業和現場環境中常見的不可預測電壓軌。峰值輸出電流為 100 mA,適合供電給感測器、發射器及其他支援電路。超低靜態電流可在低活動期間將功率損耗降至最低,有助於提升系統效率並延長電池續航力。

圖 2:採用 LT8618-3.3 的降壓穩壓器配置,輸出固定為 3.3 V。(圖片來源:Analog Devices, Inc.)

圖 2:採用 LT8618-3.3 的降壓穩壓器配置,輸出固定為 3.3 V。(圖片來源:Analog Devices, Inc.)

- LT8618EDDB#WTRMPBF 提供相同的寬廣輸入範圍和 100 mA 輸出,但輸出可在 0.778 V 至 40 V 之間調整。因此適合供電給類比、數位或參考電路,特別是需要多個電源軌的情況。就像固定輸出的款式,也結合了快速暫態響應、穩健的短路保護和熱關斷能力,可確保在完整的 -40°C 至 +125°C 工業溫度範圍內可靠運作。

憑藉此彈性,設計人員能選擇合適的穩壓器,以符合 4 至 20 mA 電流迴路系統的電壓和電流需求,確保系統可靠運作,同時將廢熱和功率消耗降到最低。

LT8618 在 Burst Mode® 運作時具有 2.5 µA 低靜態電流,不會耗盡迴路電力,能保留更多電力以供電給感測器、轉換器及通訊功能。兼具效率與低待機功耗,因此可直接克服不超出現有預算又增加更多功能的挑戰。

在 4 至 20 mA 電流迴路發射器中,印刷電路板上 LT8618 附近放置了一個小電感和輸出電容,可形成輸出濾波器,藉此平滑電壓,並穩定供電給感測器及支援電路。適當的輸入電壓,例如 24 VDC,可提供超出發射器工作電壓的足夠餘裕,並達到精準的穩壓與暫態響應,即使在迴路電流因感測器負載變化而變動時,也能確保維持穩定的供電。

LT8618 能讓發射器功能擴充,以支援進階感測器、數位邏輯及安全功能,同時不超過電流迴路的 4 至 20 mA 限制。

具有整合式保護功能,包括過壓、熱關斷及短路保護,可在嚴苛的現場環境提供穩健的功能性。LT8618 採用緊湊封裝與極少的外部元件,因此可簡化電路板佈局,這對空間受限的發射器來說特別重要。

結論

利用緊湊、高效率的切換式穩壓器 (如 ADI 的 LT8618) 取代效率低的線性穩壓器,設計人員就可克服 LDO 的限制,並在滿足現代工業應用所需的準確性、可靠性與溫度要求的同時解鎖新功能。

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。