Are New Metrics for Lighting Color Quality Moving the Goalposts Without Disrupting the Score?

資料提供者:DigiKey 歐洲編輯群

2016-07-26

Although the lighting industry has discussed methods for assessing color quality for many years, the rapid success of LED lighting has highlighted the need for an improved metric. The Color Rendering Index (CRI) has been used for many years, but LED technologies have now dramatically extended the scope for fine-tuning the characteristics of “white” light. Several alternative methods of assessment have been proposed, to address this issue. In the absence of industry consensus, Cree has found its own way of giving lighting designers the assurances they need.

CRI and its limitations

CRI is calculated according to the average change in hue measured in eight standard sample colors when illuminated by the light source under test and a reference light source at the same correlated color temperature on the black-body, or Planckian, locus. A CCT of 5000K and greater corresponds to daylight white as defined by the International Commission on Illumination (CIE). Because human perception regards daylight as giving the truest rendering of color, the more closely colors rendered by the lamp under test resemble those produced by the reference source, the higher the fidelity and the higher the CRI score. It follows that daylight has CRI of 100. Electric lighting that achieves high CRI values, close to 100, is considered preferable: people generally like to experience lighting that feels comfortable and natural whether indoors or outdoors.

As an expression of color quality, CRI has limitations that are becoming more apparent as today’s LED technologies extend the scope for fine-tuning characteristics of white light generated by phosphor-converted emitters.

Although the CIE has defined fourteen reference colors, only the first eight are used to calculate CRI. The result is the average, Ra, based on the results R1 to R8. The colors 1 to 8 are deemed to be representative of most objects. In fact, they are medium-chroma pastel colors as shown in Figure 1. The remaining six colors, including high-saturation colors (red, yellow, green, blue), skin color, and olive green do not influence the calculation of CRI. Figure 2 illustrates these six colors as defined by the CIE, as well as a 15th color, Asian skin color, as defined by the Japanese JIS standard.

Figure 1: R1-R8 colors used to calculate CRI.

Figure 2: R9-R15 colors defined by CIE but not used to calculate RI, such that CRI gives an incomplete expression for color quality that is more noticeable with LED lamps.

The current CRI method allows a lamp to achieve a high index even though its ability to render saturated colors may be impaired. Color desaturation can be particularly noticeable with reds, as these strongly influence perception of skin tones. Faithful rendering of saturated colors, especially reds, is also important in applications such as retailing and healthcare.

NIST’s Color-Quality Scale (CQS)

The lighting industry has been contemplating various alternatives to CRI for some time. NIST, the US National Institute for Science and Technology, has proposed the Color Quality Scale (CQS). According to NIST, other metrics that have been proposed include the Flattery Index, Color Preference Index, Color Discrimination Index, Feeling of Contrast Index, Color Rendering Capacity, and Gamut Area Index. None have been accepted as standards, and it appears CRI continues to be favored as it is both well established and easy to understand.

NIST’s proposal, with CQS, is to include the saturated colors among the range to be tested. Like CRI, it generates a single-number index, Qa, but in this case it is an average that represents the color-rendering quality for all colors, including saturated colors. The CQS is also designed to prevent lamps that achieve very high fidelity with some colors but give poor results with others from scoring an average good enough to qualify for a high overall index. One of the weaknesses of the CRI scheme is that such situations can occur, effectively allowing some inferior lamps to claim superior performance. The CIE has deliberated over whether to adopt CQS as a successor capable of overcoming some of the weaknesses of CRI, but has not yet reached a conclusion.

IES ups the ante

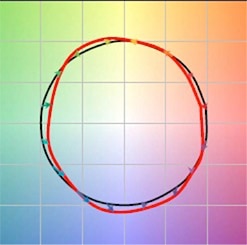

Meanwhile, the Illumination Engineering Society of America (IES) has proposed another approach that relies on even more extensive testing to evaluate light source color rendition. Known as TM-30-15, this emerging test method proposes ninety-nine color samples distributed uniformly across the color space. Moreover, TM-30-15 measures gamut in addition to fidelity, and uses a blend of reference sources at CCT between 4500K and 5500K. The test method also generates a color-vector graphic that presents a visual description of hue and saturation changes. As a result, lamp performance expressed according to TM-30-15 includes a fidelity index, Rf, a relative gamut index, Rg, and a color vector graphic (Figure 3). Although the fidelity index is calculated using a much larger number of color samples than CRI or CQS, because it is an average the possibility remains that a higher value does not always indicate better color quality. The accompanying Rg and graphic provide more information for users to assess the likely performance of a lamp in a given application.

Figure 3: TM-30-15 color vector graphic comparing test lamp (red trace) with reference (blue trace). Source: IES.

TM-30-15 has been introduced relatively recently, in September 2015, and the industry’s response is yet to become clear. It may be viewed as excessively complex and time-consuming to be attractive for commercial lighting businesses.

Despite the lack of consensus on a color-quality assessment standard that is better suited to the characteristics of LED lighting, producers of high-quality modules and light engines need to quantify product performance for the benefit of customers, and also seek to differentiate their own products from others of inferior quality.

Expressing additional scores for special colors in the R9-R15 range, measured using the established CRI test method, can give a better indication of good light quality and color reproduction. Recognizing that rendering of red colors is of greatest interest in consumer and professional applications, the Energy Star framework requires qualifying lamps to demonstrate CRI greater than 80 and R9 greater than zero. Only the CRI value is communicated to end users, and it is worth noting that at least one lighting manufacturer has suggested that allowing flexibility for R9 to vary even down to negative values can be beneficial for color quality in some applications.

For lighting targeted at applications such as retail or healthcare, where rendition of red tones with quality comparable to that produced by halogen or incandescent lamps is critical, CRI greater than 90 and R9 of over 60 have been suggested as suitable minimum benchmarks.

In the absence of consensus…

Manufacturers and end users of luminaires and modules are understood to prefer to work with a single number that expresses color quality. In the absence of an accepted industry standard that provides a better representation than CRI, Cree has gone some way toward the same goal by distinguishing its TrueWhite® brand of LED-lighting products according to both CRI and R9 performance, as well as efficacy. The TrueWhite portfolio, which includes luminaires such as troffers and downlights as well as LED modules such as the LMH020 and LMR040, guarantee CRI values of over 90 while also ensuring high R9, as well as efficacy of 130-150 lm/W and uniform warm or cool color temperatures.

TrueWhite technology utilizes various techniques to ensure precise color management and preserve reliably high color consistency over the life of the product. These include a patented combination of high-performing phosphor-converted LEDs mixed with complementary light from red and unsaturated, or blue-shifted, yellow LEDs (“BSY+R”). In addition, spectral notching technology takes advantage of properties of neodymium glass to deliver vivid indoor lighting. Doping glass with neodymium is known to increase absorption of certain wavelengths resulting in increased color gamut and greater contrast. It is a proven technique that has been used in the past with incandescent lamps.

As a proprietary measure of color quality, TrueWhite gives lighting designers an assurance of minimum performance that is particularly valuable in scenarios that are critically dependent on accurate rendering of reds. These include hospitals, where accurate reds are critical for diagnoses such as skin or wound care assessment, and where warm, welcoming lighting enhances the atmosphere for patients and visitors. Retailers can also benefit from lighting that is close to the quality of sunlight and presents saturated colors well, for example to help customers see clothes at their most attractive, or produce at its most appetizing. Car showrooms and service areas are other locations where true representation of bright, vivid colors can be important, to show vehicles at their best and make a good impression on potential buyers.

Conclusion

The lighting industry has known for some time that a more accurate index of color quality is needed to supersede CRI, one that is better suited to the needs of the LED lighting industry. Although the shortcomings of CRI are clear to see, consensus on choosing a replacement is proving difficult to achieve. Several groups have suggested alternatives that have not yet been widely adopted. Cree has set high standards across a range of parameters, for products included in its TrueWhite portfolio, which provide a reliable assurance of color quality, uniformity and energy efficiency based on metrics that are easy to understand and trusted by lighting designers.

聲明:各作者及/或論壇參與者於本網站所發表之意見、理念和觀點,概不反映 DigiKey 的意見、理念和觀點,亦非 DigiKey 的正式原則。