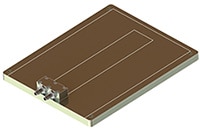

Brazed High-Performance Liquid Cold Plate

Wakefield’s vacuum-brazed cold plates have unparalleled flexibility in design

Wakefield Thermal’s vacuum-brazed liquid cold plates are created by machining two metal plates with interior channels and fin structures (zipper fin), which are then carefully sealed together inside a vacuum chamber. A filler metal with a lower melting point is melted into the joints of the cold plate via capillary action. The vacuum created in the chamber removes the atmosphere, preventing the formation of oxides that would normally form during the brazing process. Without the vacuum, a flux would be required to protect the joints as they are formed. The vacuum-brazing process creates an exceptionally strong joint and does not require any brazing flux. The vacuum-brazed cold plate has unparalleled flexibility in design and is not limited by the bending radius limitations of Wakefield Thermal’s standard tube and plate cold plates.

Wakefield Thermal’s vacuum-brazed liquid cold plates are created by machining two metal plates with interior channels and fin structures (zipper fin), which are then carefully sealed together inside a vacuum chamber. A filler metal with a lower melting point is melted into the joints of the cold plate via capillary action. The vacuum created in the chamber removes the atmosphere, preventing the formation of oxides that would normally form during the brazing process. Without the vacuum, a flux would be required to protect the joints as they are formed. The vacuum-brazing process creates an exceptionally strong joint and does not require any brazing flux. The vacuum-brazed cold plate has unparalleled flexibility in design and is not limited by the bending radius limitations of Wakefield Thermal’s standard tube and plate cold plates.

- Compatible with the industry’s most common power module devices (SiC, GaN, IGBTs, SCRs)

- High thermal performance

- Lightweight design for critical applications

- Vacuum brazed construction ensures metal-to-metal flux-free joint

- Low pressure drops for medium and low flow rates

- Leak-free (pressure tested) and corrosion-free construction

- Fully customizable to fit different size footprints

- EV/battery cooling

- Inverters

- Aerospace and defense

- UPS power supplies

- Data centers/servers

- High-power optics

- Medical

- Instrumentation

Brazed High-Performance Liquid Cold Plate

| Image | Manufacturer Part Number | Description | Available Quantity | Price | View Details | |

|---|---|---|---|---|---|---|

|  | 131097 | BRAZED HIGH PERFORMANCE LIQUID C | 7 - Immediate | $2,689.29 | View Details |