TI DLP® Technology

While known worldwide for high-quality projection applications, TI’s DLP® technology enables a diverse range of display and advanced light control applications spanning industrial, enterprise, and automotive.

How DLP Technology Works

Texas Instruments' DLP technology enables innovative optical solutions that disrupt existing end equipment and create new markets. The DLP chip, or Digital Micromirror Device (DMD), is an array of micromirrors that can be used for high speed, efficient, and reliable spatial light modulation. Not only a leader in consumer projection, DLP technology is redefining industrial, medical, telecom, security, and many other applications. With TI's powerful yet easy-to-use development tools, customers are able to reduce design cycles and deliver disruptive products.

At the heart of every DLP chipset is an array of highly reflective aluminum micromirrors known as the digital micromirror device (DMD). The DMD is an electrical input, optical output micro-electrical-mechanical system (MEMS) that allows developers to perform high speed, efficient, and reliable spatial light modulation. Using TI's proven semiconductor manufacturing capabilities, each DMD contains up to 2 million individually controlled micromirrors built on top of an associated CMOS memory cell. Since the first DLP chipset was sold in 1996, TI has produced more than 35 million DMDs for customers around the world.

During operation, the DMD controller loads each underlying memory cell with a '1' or a '0'. Next, a mirror reset pulse is applied, which causes each micromirror to be electrostatically deflected about a hinge to the associated +/-12° state. The deflection angle of these two valid states is very repeatable due to a physical stop against two spring tips. In a projection system, the +12° state corresponds to an 'on' pixel, and the -12° state corresponds to an 'off' pixel. Grayscale patterns are created by programming the on/off duty cycle of each mirror, and multiple light sources can be multiplexed to create full RGB color images. In other applications, the +/-12° states offer two general purpose output ports with a pattern and its inverse.

Why Choose DLP?

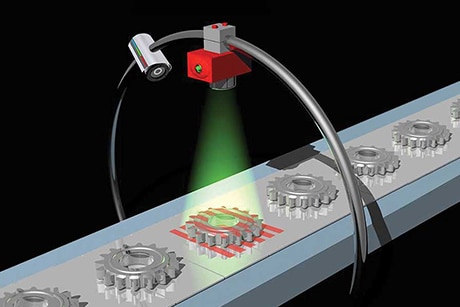

For every application, there are often multiple techniques or technologies that can be used to solve the engineering challenge at hand. In some applications, using light intelligently with DLP technology can enable completely new, disruptive solutions that displace traditional physical, chemical, or other "high touch" techniques with non-contact optical approaches. For other customers that are using optical techniques, DLP technology often allows those customers to deliver improved performance with unique technical capabilities, a reliable supply chain, extensive support infrastructure, and a lower total cost of ownership. These are just a few of the many reasons that customers using other spatial light modulators, such as liquid-crystal-on-silicon (LCoS), liquid-crystal displays (LCD), scanned lasers, and other MEMS devices, are switching to DLP technology from Texas Instruments.

Advanced Light Control

Incredibly fast pattern rates combined with ultraviolet and infrared chip portfolio for industrial applications.

Browse all devices:

Display and Projection

HD resolution, high brightness and outstanding colors to match your design needs.

Browse all devices: