Connectivity Solutions for Two-Wheelers

To meet the needs of next-generation two-wheelers, designers need to consider their connector, sensor and harness options early in the design cycle. With design requirements changing rapidly, partners like TE Connectivity (TE), provide knowledge in standard compliance requirements, and with a breadth of experience, provide a more holistic approach to system design, safety, reliability and efficient signal and power routing. From compliance to safety and sustainability, next-generation two-wheelers are on the leading edge of electromechanical system design, making it critical that designers be confident in their connector partner’s technical and innovation capabilities. With expertise in the industry and a comprehensive portfolio of rugged sensors, terminals, connectors, relays, and hybrid and electric mobility solutions, TE is enabling two-wheeler designers to transform their concepts into creations.

TE Connectivity, TE connectivity (logo), and TE are trademarks.

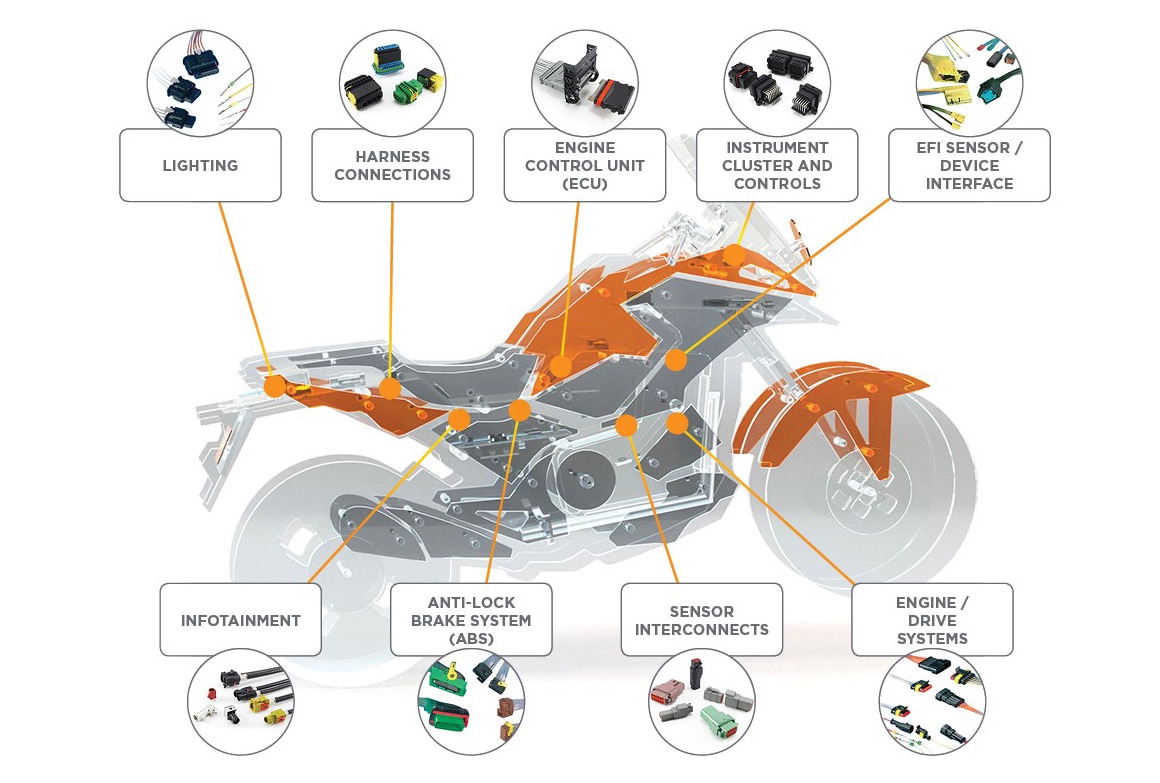

- Lighting

- Harness Connections

- Engine Control Unit (ECU)

- Instrument Cluster and Controls

- EFI Sensor / Device Interface

- Infotainment

- Anti-Lock Brake System

- Sensor Interconnects

- Engine / Drive Systems

AMP MCON Connectors

MCON is a series of contact systems commonly used for electrical and electronic applications for passenger cars and commercial vehicles. The contact design meets standardized blade sizes and interface requirements of the automotive industry. Except the miniaturized MCON 0.50 contact system, all contacts follow the two-piece contact design strategy to separate the electrical from the mechanical performance. The MCON contact series is available for sealed and unsealed applications. The new generation MCON connector system offers receptacle and tab housings with capability for waterproofing and resistance to conditions of extreme vibration. For a fast and economic termination process, TE Application Tooling offers a vast portfolio of application equipment.

DEUTSCH DT Connectors

DEUTSCH DT connectors offer field proven reliability and rugged quality. The DT design strengths include optional flange mounting, multi-pin arrangements, and design flexibility. Thermoplastic housings offer a wide operating temperature range and silicone rear wire and interface seals allow the connectors to withstand conditions of extreme temperature and moisture.

AMP HDSCS Connectors

TE Heavy Duty Sealed Connector Series (HDSCS) offers several cavity arrangements and mixed wire sizes. These rugged, thermoplastic connectors have a secondary lock with poke-yoke feature and can be used for in-line or flange mount applications. HDSCS connectors are available in five housing sizes and with four keying options. They are offered in arrangements ranging from 2 to 18 cavities.

DEUTSCH DTM Connectors

DEUTSCH DTM connectors fill the need for lower amperage, multi-pin connectors. These connectors are environmentally sealed and stand up to harsh environments. DEUTSCH DTM connectors can be mounted in-line, flanged, and used for PCB mount applications. The connectors are made of rugged thermoplastic and feature silicone rear wire and interfacial seals that allow the connectors to withstand conditions of extreme temperature and moisture.

AMP AMPSEAL 16 Connectors

AMPSEAL 16 connectors are targeted for off-road, heavy-duty industrial, recreational and agricultural applications. These connectors offer rugged reliability, easy use, and help prevent moisture and dirt from contaminating connections. AMPSEAL 16 receptacle and pin housings offer a one-piece approach and come fully assembled.

DEUTSCH DT Connectors

DEUTSCH DT connectors offer field proven reliability and rugged quality. The DT design strengths include optional flange mounting, multi-pin arrangements, and design flexibility. Thermoplastic housings offer a wide operating temperature range and silicone rear wire and interface seals allow the connectors to withstand conditions of extreme temperature and moisture.

AMP MQS Connectors

The Micro Quadlok (MQS) Series offers high packing density, robust construction and high functional requirements. The special feature of the MQS contact is the separation of the main functions; the internal contact body provides all electrical and electromechanical functions, while the superimposed steel cantilever spring protects and retains the contact.

FAKRA RF Connectors

TE offers a comprehensive connector system that is fully compatible and designed based on requirements from the FAKRA RF and USCAR standards. The connector systems are in compliance with FAKRA II and FAKRA IV standards for telematics and multi-media vehicle applications. Product offerings include RF cable assemblies, terminals and housings for use in various automotive applications.

Sealed Mini Fuse Holders

TE’s compact, IP67 rated, two position mini fuse holder accepts AMP MCP 2.8 contacts and can be mounted using standard DEUTSCH DT and AMPSEAL 16 connector mounting clips. This sealed mini fuse holder is engineered for reliability in applications where failure is not an option. Constructed of heavy-duty thermoplastic to withstand severe vibration and mechanical shock, this fuse holder can accommodate two active fuses and two spares.

AMP MQS Connectors

The Micro Quadlok (MQS) Series offers high packing density, robust construction and high functional requirements. The special feature of the MQS contact is the separation of the main functions; the internal contact body provides all electrical and electromechanical functions, while the superimposed steel cantilever spring protects and retains the contact.

DEUTSCH DTM Connectors

DEUTSCH DTM connectors fill the need for lower amperage, multi-pin connectors. These connectors are environmentally sealed and stand up to harsh environments. DEUTSCH DTM connectors can be mounted in-line, flanged, and used for PCB mount applications. The connectors are made of rugged thermoplastic and feature silicone rear wire and interfacial seals that allow the connectors to withstand conditions of extreme temperature and moisture.

AMP MCON Connectors

MCON is a series of contact systems commonly used for electrical and electronic applications for passenger cars and commercial vehicles. The contact design meets standardized blade sizes and interface requirements of the automotive industry. Except the miniaturized MCON 0.50 contact system, all contacts follow the two-piece contact design strategy to separate the electrical from the mechanical performance. The MCON contact series is available for sealed and unsealed applications. The new generation MCON connector system offers receptacle and tab housings with capability for waterproofing and resistance to conditions of extreme vibration. For a fast and economic termination process, TE Application Tooling offers a vast portfolio of application equipment.