Advanced Semiconductor Tape-and-Reel Transport Solutions from 3M

Safe and secure transport between the stages of the semiconductor fabrication process is critical for maximizing chip and chiplet yield. As chip architectures evolve to 2D, 2.5D and 3D in pursuit of smaller footprints, better power management and overall performance, the risks to chip integrity during transportation are significant due to the complex architecture. 3M™ Polycarbonate Carrier tapes are available in a range of precision manufactured designs and solutions to help minimize die migration and cracking and to help reduce pick-up failure. Plus, these tapes are available in transparent form, are compatible for clean room use and can offer additional features such as traceability that meet the needs of your manufacturing processes.

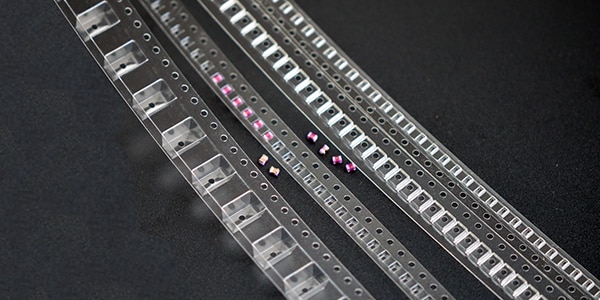

3M™ Component Carrier Tapes

Shrinking components require sturdy carrier tapes with precise pocket formation to help reduce the risk of component tilt, flip or migration that can lead to component damage and downtime in the pick and place process. 3M offers a full array of non-conductive and static dissipative products with precision pocket designs for various components.

3M™ Cover Tapes

3M™ Cover Tapes seal 3M component carrier tapes to help protect electrical and electronic components during transport and storage. 3M cover tapes offer excellent sealing properties and smooth peel force to help ensure efficient pick and place operations. The full 3M line of cover tapes includes non-conductive and static dissipative products with heat activated (HAA) or pressure sensitive adhesives (PSAs).

Features

- Precise pockets

- Tight tolerances

- Low defects

3M provides tape solutions for

- Molded plastic

- Passive device

- WLCSP/bare die

- Discrete

- LEDs

Advantages

- Better die protection capability

- Enlarged process window

- Less pocket nesting issue after winding

Benefits

- Improved line speed and uptime

- Increased yield

- Increased reliability

- Solve die migration and crack issues

- Enhance productivity through easy and efficient application

Capability and Compatibility of 3M™ Polycarbonate Carrier

Polycarbonate material is very strong and stands up to impact which can damage delicate chips and components. Its shrinkage percentage is much lower than that for materials like polyester, helping keep the pockets stable even when properly stored for long periods (up to five years). This helps maintain accurate feeding and pocket position and helps reduce the possibility of component sticking.

Capabilities

| Product | 10,000 Cleanroom | Static Dissipative | Open Radius Control | 2D Barcode |

|---|---|---|---|---|

| 3000 | ✓ | |||

| 3000R | ✓ | ✓ | ||

| 3002 | ✓ | ✓ | ||

| 3000BD | ✓ | ✓ | ||

| 3000UP | ✓ |

Compatibility

| Product | Materials | Cover Tape PSA | Cover Tape HAA |

|---|---|---|---|

| 3000 | Polycarbonate | ✓ | ✓ |

| 3000R | Polycarbonate | ✓ | ✓ |

| 3002 | Polycarbonate | ✓ | ✓ |

| 3002R | Polycarbonate | ✓ | ✓ |

| 3000BD | Polycarbonate | ✓ | |

| 3000UP | Polycarbonate | ✓ | ✓ |

Additional Resources

3M Polycarbonate Carrier Selection Guide