Weather Events Create Supply Chain Challenges That Good Planning Can Mitigate

Hurricanes Helene and Milton recently slammed the US East Coast, while Taiwan got hit by typhoon Krathon. Behind the devastating headlines, these storms also impacted supply chains for manufacturers and consumers. For manufacturers, it was a reminder of how severe weather events can bring down the regular operation of the global electronic supply chain in unexpected ways.

At first glance, it is easy to name some potential difficulties. For example, ports and roadways can flood and close, making moving components and materials from one place to another more difficult. In the wake of Hurricane Helene, the American Journal of Transportation1 predicted that Hurricane Milton would impact 12,410 sites, including manufacturing, warehousing, distribution, fabrication, and testing. Milton would affect the availability of 97,000 different parts and the manufacturing of 11,000 products. Meanwhile, pundits say that Krathon didn’t put a crack in the supply chain, but it did make a dent in the demand as other types of organizations took a break during the storm.2

Some impacts are more subtle. For example, Hurricane Helene is expected to impact the availability of high-purity quartz (HPQ), a critical raw material used in the semiconductor, solar energy, and electronics industries, according to Resilinc3, which tracks supply chain related events. The hurricane temporarily shut down HPQ mining operations in Spruce Pine, North Carolina, the world’s largest source of ultra-pure quartz. In fact, Spruce Pine provides around 80 to 90% of the world’s HPQ used in high-tech manufacturing. The shutdown will likely lead to scarcity and higher prices for quartz across the supply chain. It has also led quartz suppliers worldwide to consider ways to tap into the unmet demand with alternatives.

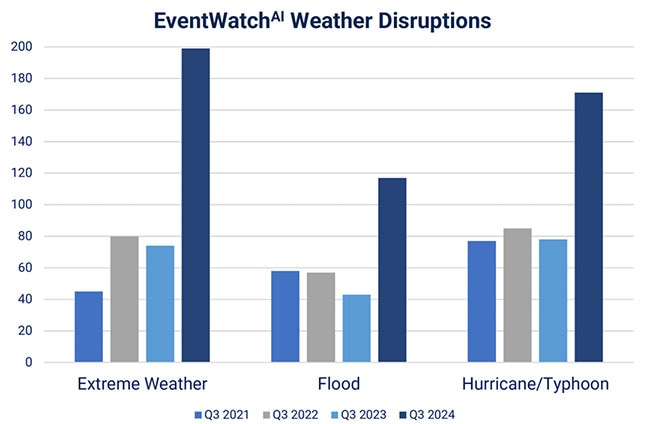

You aren't alone if you’ve noticed an uptick in weather-related events. Research has shown that 2024 has been a particularly harsh year. For example, Resilinc has tracked weather disruptions over the past four years and has seen significant increases across the board for hurricanes, typhoons, floods, and severe weather events in Q3 2024 compared to the same period in the previous three years (Figure 1).

Figure 1 : Resilinc tracked weather disruptions over the past four years and recorded substantial increases across the board for weather events in Q3 2024 compared to the same period in the previous three years. (Image source: Resilinc)

Figure 1 : Resilinc tracked weather disruptions over the past four years and recorded substantial increases across the board for weather events in Q3 2024 compared to the same period in the previous three years. (Image source: Resilinc)

In Q3 2024, Resilinc tracked 199 extreme weather events, 117 flood events, and 171 hurricane/typhoon events. Hurricane and typhoon notifications increased by 119% from Q3 2023 to Q3 2024. Extreme weather events include thunderstorms, tropical storms, tropical pressures, snowstorms, heavy winds, small storm systems, hailstorms, heavy rains, landslides, heat waves, extreme freezes, smog, and dust storms.

A failure to plan is a plan to fail

Planning for supply chain resilience is the best way to withstand extreme weather. By understanding that the business environment can be impacted by unpredictable changes such as hurricanes, earthquakes, and floods (and, dare I say, pandemics), organizations can put practices in place to mitigate the risk. Here are some general ways to plan for supply chain resilience:

- Identify vulnerabilities: Understand the supply chain's vulnerabilities, especially in planning, transportation, financial resiliency, and supplier networks. Look at each tier of suppliers for potential weather or related risks.

- Conduct risk assessments: Regularly assess risks to identify potential weather-related weaknesses and ensure your risk management plan is up-to-date and relevant.

- Strengthen supplier relationships: Prioritize supplier relationships to improve processes and ensure both parties benefit.

- Diversify: Diversify the supply chain across suppliers, manufacturing locations, transportation, and distribution.

- Plan strategically: Synchronize all supply chain components to improve visibility, agility, and production.

- Consider nearshoring: In case of catastrophic events, having supplier and manufacturing partners in a variety of locations, some closer to home, can be beneficial.

- Build inventory buffers: Strategically build a vital component’s inventory to avoid manufacturing slowdowns.

Further, if you are in an area with a potential for hurricanes, it is essential to have people dedicated to creating, testing, and implementing a hurricane preparedness plan. Consider the potential threats to your organization and its key partners and assemble a team that proactively considers those threats and their potential impacts. For example, storms can submerge roads and damage structures; strong winds can bring down power and communication lines or uproot trees that block roads. Once you identify the risks, you can determine the potential problems and work to mitigate their effects.

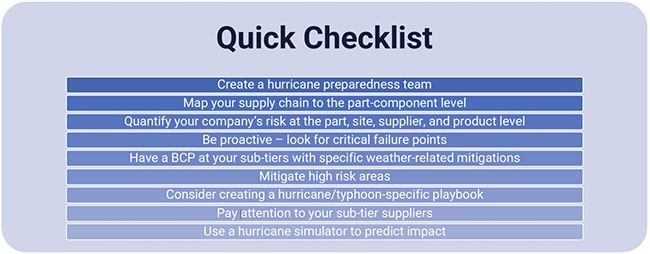

To this end, Resilinc provides a quick checklist to help you stay proactive in the face of severe weather and other natural disasters (Figure 2).

Figure 2 : Resilinc offers a checklist to stay proactive in the face of natural disasters. (Image source: Resilinc)

Figure 2 : Resilinc offers a checklist to stay proactive in the face of natural disasters. (Image source: Resilinc)

A business continuity plan (BCP) can make the difference between a short outage and a long one, but it's essential to talk to suppliers about their own BCP.

It’s wise to be concerned about severe weather or other natural disasters. Electronics OEMs must develop and adhere to a careful plan to keep the supply chain up and ready during a disaster. Pay attention to your company and suppliers to develop a strategy across your entire supply chain.

References:

1: https://www.ajot.com/news/hurricane-milton-supply-chain-impact-by-the-numbers

2: https://www.digitimes.com/news/a20241004PD207/taiwan-supply-chain-kaohsiung-typhoon-strike.html

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum