Understanding RC Power System Basics

Introduction

Radio-Controlled (RC) onboard power systems used to be quite basic with only a receiver and some servos energized by a NiCad battery. Since then, with the introduction of electric drive motors and other power demands, RC systems have changed quite a bit. This blog explains the terminology and components used in modern RC power systems and how those components are commonly configured.

The Receiver

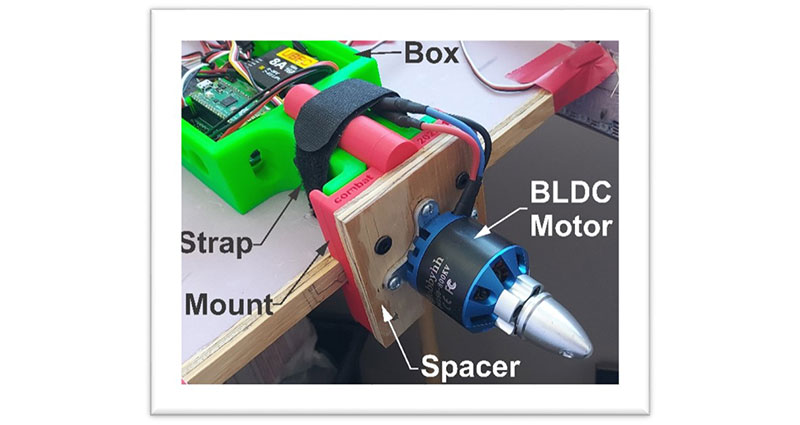

RC receivers (RX) serve two purposes. The first is to interpret signals from the transmitter and direct that data to the proper channel. The second is to provide a power rail that delivers current and voltage to the various servos or other peripheral devices that occupy the servo channels. The RX needs a steady supply of 4.8 to 6 VDC to perform its control tasks (Figure 1). If the RC model is propelled by a nitromethane or gas engine, a NiCad or NiMH battery that can supply voltage to the receiver is all that is needed. In some cases, RC vehicles with gasoline engines will have a separate battery for the ignition system.

Figure 1: RC Receiver Layout. (Image source: Don Johanneck)

Figure 1: RC Receiver Layout. (Image source: Don Johanneck)

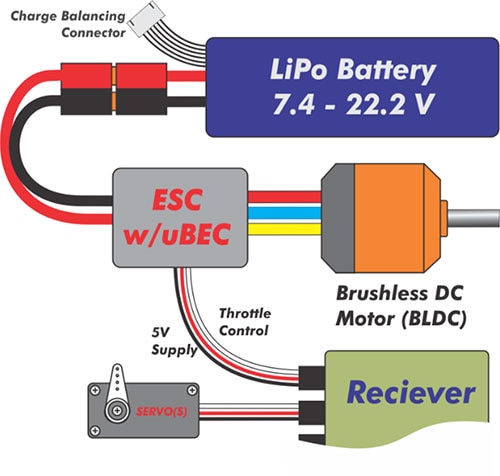

Electric Drive Motors

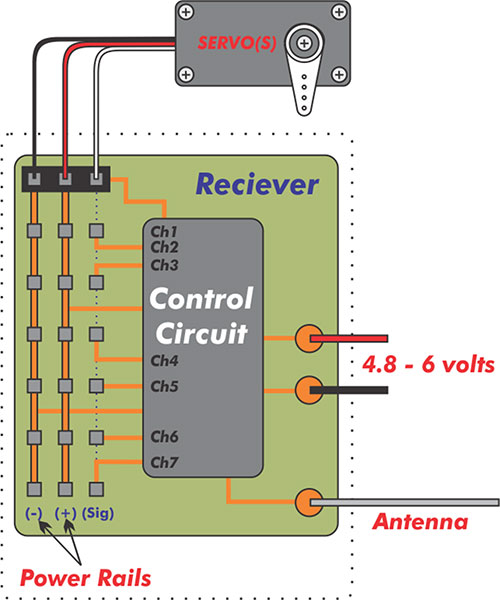

The introduction of electric motors to propel a model requires higher powered batteries and an independent throttle control system. The motor control takes the throttle signal from the RX and translates it across the battery voltage range to give the motor everything it needs. To satisfy the RX power needs, some motor controllers include a dedicated and regulated 5-volt output just for the RX and is referred to as a Battery Elimination Circuit or BEC. This allows systems designers to avoid installing two batteries. One for the motor and one for the RX. An independent BEC that ties directly to the battery can also be installed if the controller does not have a BEC or its 5V output does not provide adequate current.

Brushed or Brushless Motor?

Brushed DC motors for propulsion in RC aircraft were short lived and were quickly replaced by brushless DC motors (BLDC). The controller for motors is referred to as an Electronic Speed Control or ESC. ESC’s are rated by the output wattage and its ability to handle a variety of LiPo batteries which have taken over the RC battery market due to their high capacity. Most ESC’s have a BEC as mentioned earlier but some do not. The term BEC normally refers to a linear regulated circuit which is inefficient and generates heat. This brought about the uBEC which is a more efficient, switching type voltage regulator.

Figure 2: RC Power and Control System. (Image source: Don Johanneck)

Figure 2: RC Power and Control System. (Image source: Don Johanneck)

Where brushed motors are rated simply by input voltage and current draw, the more popular brushless motor is rated in Kv which is basically RPMs per volt. If your brushless motor is rated at 850 Kv, it will spin 850 rpms per volt applied. A 4S LiPo battery, delivers about 14.8 volts which will spin the 850 Kv motor at 12,580 rpm at maximum battery current and no load on the motor’s output shaft. The ESC regulates the voltage to give a full range of RPM control that is proportional to the position of the throttle control of the transmitter (TX).

Determining the potential current draw of a brushless motor requires a bit of fuzzy math. Taking the weight of the motor in grams and multiplying it by a factor of 3.5 gives the approximate max wattage. Assume the 850 Kv motor weighs in at 174 g. That motor may consume about 600 watts of power. As wattage is the product of voltage and current, divide the wattage by the applied voltage to get the approximate current draw which is around 41 Amps at full RPM.

Generally, an RC operator will not run at full throttle for the duration of a flight or drive but if they did, a 6500 mAh pack may run an 850 Kv motor at full load for about 9.5 minutes (6500 mAh/41000 mA = 0.1585 hours).

LiPo Batteries

The terms LiPoly, Lithium Polymer or “LiPo” refer to the same type of high output batteries. They are chosen based on what the ESC can manage and the requirements of the motor. Conveniently, most LiPo batteries provide this information on the battery label which breaks down into cell count, amp hour rating, and discharge rate. The voltage rating correlates directly to the cell count. As each LiPo cell puts out a nominal 3.7 volts, the “S” or series value relates to how many cells in series make up the battery pack. A 2S pack is 7.4 volts, 3S is 11.1 volts and so on. The amp hour rating is used to determine how long the pack can deliver current at a known current draw. DigiKey has a useful tool for calculating battery life based on current draw (Figure 3).

Figure 3: Estimated Flight Time - DigiKey Battery Life Calculator. (Image source: DigiKey)

Figure 3: Estimated Flight Time - DigiKey Battery Life Calculator. (Image source: DigiKey)

The “C” rating describes the maximum current draw from the pack that will not result in cell damage. Simply multiply the “C” rating by the capacity in amps. A 15C, 3200 mAh pack can deliver a max draw of 48 amps. The “C” rating is useful in determining the charge rate as well (Figure 4). Charging a LiPo battery properly takes discipline to prevent cell damage and the potential for fire caused by overcharging or physically damaged cells. Always use a charger with adjustable charge rates, balance lead connectors and, if available, a sensor to monitor pack temperature. A “puffy” pack or packs with visible cell damage should be properly discarded to prevent combustion or explosion during charging. It is common practice to choose a 1C charge rate which is calculated by converting the mAh rating to amps and charging at that rate. The 3200 mAh pack mentioned earlier is charged at 3.2 amps (1C) max. The balance lead ensures the pack is charged evenly and allows the user to monitor each cell using a special meter that attaches directly to the balance lead.

Figure 4: Estimated Charge Time - DigiKey Battery Life.Calculator. (Image source: DigiKey)

Figure 4: Estimated Charge Time - DigiKey Battery Life.Calculator. (Image source: DigiKey)

Be careful not to discharge a pack below 3.7 volts per cell. Persistent discharging below this level can shorten battery life and reduce capacity.

A severely damaged pack due to overcharging or physical damage can burst apart beyond its protective packaging and is referred to as being “tacoed” as it looks like a taco shell. Do not attempt to charge and be careful when handling a tacoed pack. They are volatile and unpredictable at that point. For safety, LiPo packs must be neutralized and recycled when no longer useable.

Summary

RC power systems can be simple and inexpensive or range into the hundreds of dollars. Either way, proper interconnections and diligent battery monitoring can extend the life of the power system. It is common for the power system to last many years or even decades. Properly cared for batteries may last several seasons but often need replacement due to the constant rapid discharging associated with RC vehicles, but think of all the fun you are having!

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum