Three Key Technologies Warrant Supply Chain Investment in 2022

Budgets by their nature are limited. Supply chains, by their nature, focus on optimizing some combination of cost and resilience. That means that chief supply chain officers (CSCOs) have a critical and difficult job: choosing the right way to invest supply chain dollars in technology to create the most favorable impact.

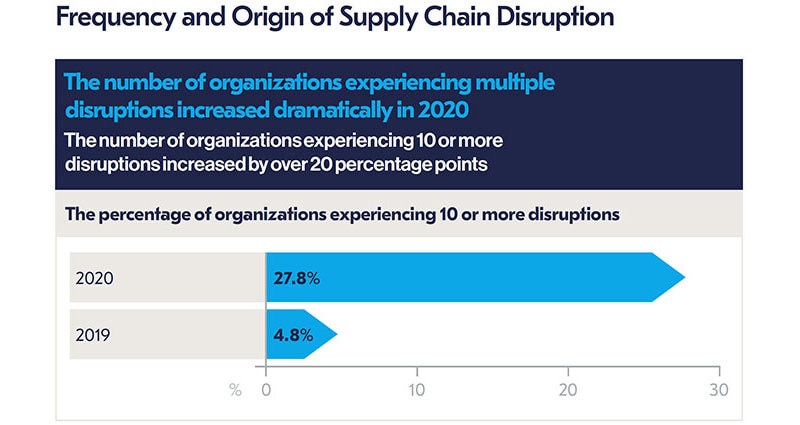

It’s a tough job—every department and function has its own pet projects that promise some sort of return. That means that the supply chain will have dozens or even hundreds of competing initiatives that are clamoring for investment. Gartner’s supply chain hype cycle illustrates this abundance (Figure 1).

Figure 1: A wealth of technologies are being applied to the work of gathering supply chain insights and making strategic decisions more quickly. Some, though, are more mature than others. (Image source: Gartner, October 2021)

Figure 1: A wealth of technologies are being applied to the work of gathering supply chain insights and making strategic decisions more quickly. Some, though, are more mature than others. (Image source: Gartner, October 2021)

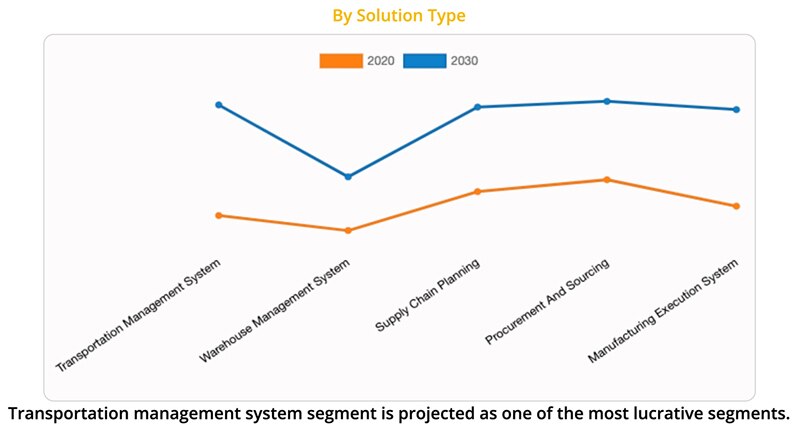

Market growth is also notable: analysts expect the supply chain management market to grow 10.7% year over year through 2030, taking the market from $18.7 billion to $52.6 billion.1 Currently, cost optimization and resilience are top priorities in the corner office making supply chain decisions, according to a recent Gartner survey of nearly 200 CSCOs.2

Figure 2: Over the next decade, the supply chain management market will grow substantially, with much focus being put on elevating supply chain visibility. (Image source: Allied Market Research)

Figure 2: Over the next decade, the supply chain management market will grow substantially, with much focus being put on elevating supply chain visibility. (Image source: Allied Market Research)

Today, there are already two supply chain technologies that have reached the level of bread-and-butter in the average supply chain: cloud computing and storage and inventory and network optimization tools.[1] There are others that need to be added to the list of must-haves in the not-to-distant future. Gartner pointed to three at its Gartner Supply Chain Symposium last month:

- Artificial intelligence

- Supply chain risk management (SCRM)

- Supply chain center of excellence (SC CoE)

Let’s take a look at what these technologies are bringing or will bring to the supply chain.

Putting AI brains in the operation

For sure, the use of artificial intelligence (AI) in the supply chain is currently in its infancy, but I’m confident it’s going to help build supply chains that are both agile and flexible—and much less reliant on human intervention for day-to-day problems. Leveraged correctly, AI can analyze large volumes of data, trace relationships in that data, and use that analysis to proactively provide better operational visibility and suggest the best path forward. It's also adaptive and provides visibility across multiple tiers of the supply chain.

The potential boon is broad and hits at the heart of some of the biggest supply chain challenges I’m seeing out there. For example, pricing and demand forecasts promise to be timelier and more accurate, always a good thing. In procurement, manufacturers can build better data integration with suppliers to smooth out supply and demand wrinkles and address shifts in pricing and availability. It can also be applied to logistics (optimization of freight, contracts, etc.) and production (agile production planning and scheduling).

Reducing risk, increasing resilience

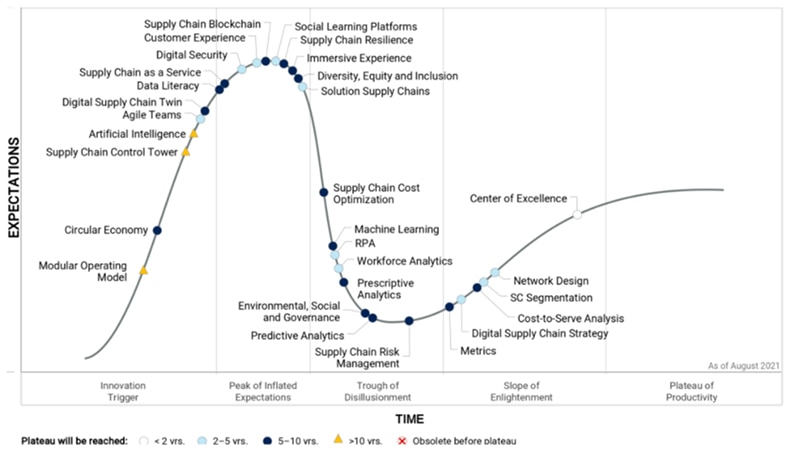

Risk, remember, is not a matter of if something unexpected will happen, but rather of knowing that it will happen—and being ready to address it. Covid-19 reinforced the importance of risk management, as do shifting trade restrictions and natural disasters such as fires, hurricanes, and floods. And who can forget the aftermath of the Fukushima nuclear plant disaster?

Today, many supply chains have risk mitigation plans, but they often don’t address the reality of what actually impacts the supply chain. We need to get more savvy about identifying and mitigating risks throughout the extended supply chain. That is: we may know our risk, but we also need to understand our partners’ risks—and their partners’ risks—in order to be ready for product shortages, production interruptions, and supply delays.

Pursuing excellence

A third area that electronics manufacturers should zero in on is a supply chain center of excellence (CoE). That’s a very fancy way of making sure that the organization constantly pursues operational improvement—and creates strategies for tracking and measuring success.

Although as many as eight out of ten supply chain organizations have CoEs, it remains important to commit to constantly monitoring supply chain functions, capabilities, and processes to ensure that they are up to snuff. There are always things to be done to increase the effectiveness of people, processes, or technologies in the organization. In short, this is the function that ensures that the organization can see and successfully implement the next big supply chain technology that will make the organization that much more efficient and flexible.

Our world is well past the stage of organizations needing to hop on every new technology that comes along. There’s not enough money in any organization to do that. At the same time, luddite organizations are doomed to extinction. The winners are going to find a balance of mature and emerging technologies that tie directly to key business objectives and recognize and support the strategic importance of the supply chain. Invest carefully, and supply chain excellence will likely follow.

References

1: https://www.alliedmarketresearch.com/supply-chain-management-software-market

3: mhi.org/publications/report (Source: Deloitte, MHI)

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum