Silent Tech Heart: How Piezoelectric Ceramics Drive an Intelligent Future

From deep-sea exploration devices to medical ultrasound probes, capturing images from precision industrial equipment to the touchscreens of smart terminals, a sophisticated functional material—piezoelectric ceramics—is driving technological advancement and reshaping human-machine interaction. Its core principle is the piezoelectric effect and the inverse piezoelectric effect inherent in its unique crystal structure: applying mechanical force generates an electrical charge (direct effect, enabling sensing); applying an electric field induces precise deformation or vibration (inverse effect, enabling actuation and sound generation). It is this bidirectional, near-instantaneous conversion between mechanical energy and electrical energy, combined with excellent physical strength, chemical stability, and cost advantages, that makes piezoelectric ceramics a core solution in fields like acoustic sensing, energy conversion/control, and precision actuation.

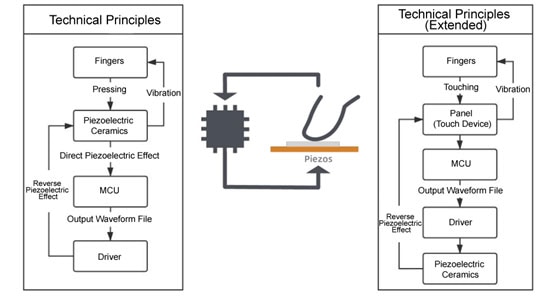

The piezoelectric effect can both generate an electrical charge from applied external pressure and cause vibration from an applied electrical field. (Image source: BeStar Technologies, Inc.)

The piezoelectric effect can both generate an electrical charge from applied external pressure and cause vibration from an applied electrical field. (Image source: BeStar Technologies, Inc.)

Riding the wave of continuous iteration in the electronics information industry, piezoelectric devices are also constantly innovating and upgrading. Devices featuring novel structures exhibit higher energy density, faster response times, and enhanced system integration capabilities, fully meeting the escalating demands across diverse and growing fields, from industrial automation to consumer electronics and healthcare.

Amidst this technological evolution, BESTAR leverages its deep expertise in piezoelectric ceramics. Through continuous innovation in material formulations, device design, and manufacturing processes, the company has built a mature, reliable, and comprehensive product ecosystem that closely addresses cutting-edge requirements.

Acoustic Optimization: Ultrathin Hi-Fi Solution

BESTAR's multilayer piezoelectric ceramic actuators operate based on the inverse piezoelectric effect. Using minimal current (typical power consumption ~0.1 W at 1 kHz), they drive ultrathin ceramics (approximately 0.5 mm) to produce precise vibrations. Their ultra-thin profile and micro-power characteristics make them exceptionally suited for space-constrained scenarios. Furthermore, they eliminate the need for external sound apertures, significantly simplifying panel processing, reducing manufacturing costs, and unlocking industrial design potential. Simultaneously, thanks to the inherent advantages of ceramic materials—wide frequency bandwidth and high transient response—this solution accurately reproduces high-resolution (Hi-Res) audio sources (24 bits/192 kHz). It authentically recreates rich details and dynamic range surpassing CD quality, faithfully conveying immersive live sound and subtle nuances of performance, laying a solid foundation for the next generation of high-fidelity audio systems.

BeStar’s piezo actuators are capable of producing high-fidelity audio. (Image source: BeStar Technologies, Inc.)

BeStar’s piezo actuators are capable of producing high-fidelity audio. (Image source: BeStar Technologies, Inc.)

Fingertip Dialogue: Haptic Feedback Reshaping Interactive Perception

In the realm of touch interaction, BESTAR's haptic feedback solutions precisely utilize the inverse piezoelectric effect, instantly converting electrical signals into perceptible touch sensations. Its core piezoelectric ceramic actuators are integrated within the touch panel. When specific voltage waveforms are applied, the device rapidly generates microscopic deformation based on the inverse piezoelectric effect, delivering subtle mechanical vibrations directly to the user's fingertips. The realistic and differentiated tactile sensations achieved through this high-fidelity "electrical signal → mechanical vibration" conversion provide users with an unprecedented immersive haptic feedback experience.

With haptic feedback, touch panel users can feel a vibration indicating a positive touch has been made. (Image source: BeStar Technologies, Inc.)

With haptic feedback, touch panel users can feel a vibration indicating a positive touch has been made. (Image source: BeStar Technologies, Inc.)

As a functional material powering modern technology, the core capability of piezoelectric ceramics—efficient and precise energy conversion—is indispensable in cutting-edge fields like electronic information technology, high-end equipment, aerospace, and precision medicine. With ongoing breakthroughs in materials science, precision manufacturing, and intelligent control technologies, the performance boundaries of piezoelectric ceramics will continue to expand. Its application scenarios will extend beyond sensors, transducers, and actuators into emerging fields such as flexible electronic sensing, micro-robotic drives in biomedicine, and precision micro/nano-manipulation.

The future will see piezoelectric ceramics, this silent "tech heart," continue to pump robust, yet precise driving force into our increasingly intelligent world.

See BESTAR's available parts on the DigiKey website to learn more about these technologies and product details.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum