Potting Delivers Protection and Quality Performance

Hooked on potting? Well, then keep reading. It will please some of you to know that this blog is not about gardening, plants, or kitchen instruments. Rather, we are still talking about the electronic industry and potting with potting-capable connectors. PCB potting is a method used to protect electronic circuit boards by filling an enclosure with a liquid material called potting compound or encapsulation resin. The potting compound fills the device’s housing and, in most cases, covers the entire circuit board and its components, although in some cases, it can be used to pot individual components.

Do you ever feel like your connectors are just asking to be potted? It makes sense. Connectors are small and defenseless components in power devices. They are exposed to dust, moisture, heat, shock, and vibration which can all lead to connection failure. Imagine an HVAC system that is outside getting rained on regularly, an electric lawn mower running on a hot 80-degree sunny day, or a consumer video game system that gets unintentionally spilled on with food or liquid. Potting is the solution to deliver protection against these elements and provide long-lasting quality performance.

Potting is the sealing of the rear of a connector with a potting compound or resin filling an outside casing, which settles to form a solid. Molex connectors are potting qualified with drain hole-free designs for low-power and signal product families such as Micro-One, Nano-Fit, and more offering numerous benefits that traditional connectors often lack. This blog explores the advantages of potting-capable connectors since electronics and harsh environments do not mix well.

A transparent potting compound covers the entire PCB and the back side of the connectors fighting back against the harsh elements. (Image Source: Molex)

A transparent potting compound covers the entire PCB and the back side of the connectors fighting back against the harsh elements. (Image Source: Molex)

Lightweight Strain Relief

In modern engineering and manufacturing, there are a lot of space constraints and requirements to fit a certain number of connectors and cables in tight spots. This can lead to strain on the connectors or terminal back out if there is not enough room for the cables and connectors to co-exist peacefully. Molex recommends following the “Dimension T” (see image). The “T” dimension defines a “free” length of wire, or a length of wire that is not subject to significant bias by external factors such as a wire tie, wire twisting, or other means of bending or deforming the wires that reposition them from their natural relaxed state or location where they enter the housing. The T Dimension has different measurements depending on the product family, but these measurements can be found in each product specification. For example, a Mini-Fit MAX six circuit part number has a T Dimension that measures 12.70 mm before the cable should be bent. After aligning the T Dimension, potting these areas offers a lightweight strain relief since the resin adds strength to the whole assembly. Potting relieves pressure off the terminal connection and/or cables increasing reliability and longevity.

Molex recommends following the ‘T Dimension’, allowing a bend radius after a specific measurement to protect the electrical connection of the cable assembly. (Image Source: Molex)

Molex recommends following the ‘T Dimension’, allowing a bend radius after a specific measurement to protect the electrical connection of the cable assembly. (Image Source: Molex)

Retention Force on PCB

Potting-capable connectors offer enhanced stability because the resin acts as a solid to prevent headers or housings from coming loose on a PCB. The potting compound reinforces the connector, making it more resistant to vibration or shocks. By maximizing the retention force, connectors go through much less mechanical stress and can prevent disconnections or damage to the connector. Potting is valuable in applications where connectors are subject to constant movements, like a power drill or washing machine.

Electrical Insulation

By reducing the risk of dreadful and unmentionable short circuits and electrical malfunctions, potting material acts as a dielectric barrier, preventing current leakage and maintaining signal integrity even in challenging environments. Potting reduces the possibility of failures in this area by providing surface-to-surface coverage and a significant improvement in overall reliability and durability.

The Micro-Lock Plus connectors reduce connector electrical failure by using a potting compound protection layer. (Image Source: Molex)

The Micro-Lock Plus connectors reduce connector electrical failure by using a potting compound protection layer. (Image Source: Molex)

Manufacturing Breeze

Potting is an easy and low-cost solution compared to connectors that are sealed or IP rated because it reduces manufacturing and maintenance costs for new and existing designs. By simplifying the manufacturing process, either manual or automatic potting saves time and precisely surrounds the connectors allowing consistency and worry-free installation if you are following the connectors’ maximum potting heights to not interfere with mating capabilities or latch designs.

The CAD drawing illustrates the maximum potting height on a Mini-Fit connector to ensure the latch design and mating of the connectors are not compromised. (Image Source: Molex)

The CAD drawing illustrates the maximum potting height on a Mini-Fit connector to ensure the latch design and mating of the connectors are not compromised. (Image Source: Molex)

| Product Family and Pitch Size (mm) | Series Numbers | Potting Height MAX (mm) |

| Micro-Lock Plus 1.25 | 205957, 207760 | 3.00 |

| Spot-On 1.50 | 201648, 201645, 201646 | 5.00 |

| Spot- On 2.00 | 201201, 201197 | 7.00 |

| MicroTPA 2.00 | 55487 | 7.00 |

| Micro-One 2.00 | 217063 | 7.00 |

| Mini-Lock 2.50 | 53517 | 6.00 |

| Nano-Fit 2.50 | 105312, 105310 | 4.00 |

| Micro-Fit 3.0 | 44432 | 4.10 |

| Micro-Fit+ 3.0 | 206832 | 3.45 |

| CP- 3.30 | 212210 | 7.50 |

| Ultra-Fit 3.50 | 172299, 172298 | 6.55 |

| Mini-Fit 4.20 | 5566, 172447 | 5.50 |

| Mini-Fit MAX 4.20 | 212520 | 6.67 |

| Mega-Fit 5.70 | 76829, 172065 | 7.26 |

Molex has through-hole and surface-mount termination options for potting with pitch sizes ranging from 1.25 mm all the way up to 5.70 mm. Micro-Lock Plus 1.25 mm product family is the smallest wire-to-board “potting” connector with a 3.00 mm high potting material to safeguard contact and latch areas in applications requiring environmental protection. Molex’s Fit Families have recently passed potting qualification with drain-hole-free designs, Mega-Fit being the largest potting-capable connector in low power and signal options with a maximum potting height of 7.26 mm. Molex’s expert engineering teams are available to provide industry-leading design support by providing you with data to successfully use potting connectors. The recommended maximum potting height for each product family ensures durability with added walls to protect our unique positive lock from being immersed into the potting material. All while avoiding connection failures and preventing ingress of dust or moisture.

Environmental Influencers

Potting-qualified connectors provide superior environmental protection, making them ideal for applications in harsh and challenging environments. The protective layer of the potting compound shields the connector from moisture, dust, and chemicals, and even prevents corrosion. As a result, potting-capable connectors can withstand extreme temperatures, humidity, and exposure to corrosive substances, ensuring a proper connection in these elements.

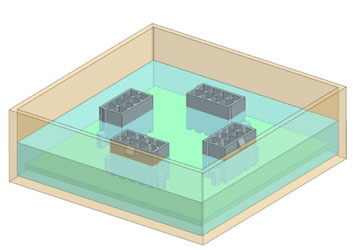

The testing CAD model showcases headers after the potting resin has been poured onto the PCB and into the case. (Image Source: Molex)

The testing CAD model showcases headers after the potting resin has been poured onto the PCB and into the case. (Image Source: Molex)

Conclusion

Potting-qualified low-power and signal connectors offer many benefits that make them a preferred choice for various electronic applications. From enhanced environmental protection and mechanical stability to improved electrical insulation and overall protection, the advantages of potting connectors create longer lifespans for power applications. By considering these benefits and incorporating potting connectors into your designs, you can enhance the durability and reliability of your electronic systems while meeting the demands of increasingly challenging environments.

Web Links:

- Molex Potting Video and Potting Product Brief from molex.com: https://www.molex.com/content/dam/molex/molex-dot-com/en_us/pdf/product-briefs/987652-6561.pdf?inline

- Fit Family Potting Application Specification: https://www.molex.com/content/dam/molex/molex-dot-com/products/automated/en-us/applicationspecificationspdf/172/172299/1722990000-AS-000.pdf?inline

- Video: https://www.digikey.com/en/videos/m/molex/molex-lowpower-and-signal-pottingcapable-vertical-headers

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum