People & Machines Must Collaborate for Successful Supply Chain Management

2024 is speeding by, with more than half the year gone. As summer slows things down for many, it’s a good time to look at the trends driving the supply chain now and in the coming months. Technology will play a huge role in where we are going, but more importantly, successful organizations will capture a competitive advantage through the intelligent and careful integration of humans and machines.

Technology boom

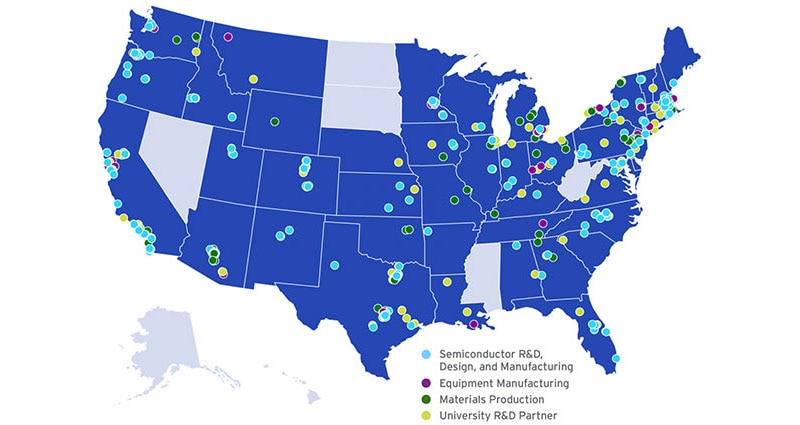

By all measures, the thirst for supply chain technology is nearly unquenchable, with analysts viewing the category as the most robust and growing enterprise software segment. According to Research and Markets, the global supply chain management (SCM) software market reached a value of nearly $36.7 billion in 2023. With a compound annual growth rate (CAGR) of 18.1% between 2023 and 2033, it predicts that the market will reach $194.3 billion (Figure 1).1

Figure 1 : The SCM software market is predicted to reach $194.3 billion in 2033. (Image source: Research and Markets)

Figure 1 : The SCM software market is predicted to reach $194.3 billion in 2033. (Image source: Research and Markets)

Supply chain themes emerge

I read with interest a list of top trends in supply chain technology for 2024 that Gartner published. It’s a list that has evolved dramatically even in the last five years. Back then, the focus was on blockchain, the Internet of Things (IoT), and digital twins.2 Artificial intelligence (AI) was on the list, but few of us had anything beyond a rather vague notion of how it could be used other than “automation” by large enterprises. Since then, AI has become affordable and applicable, even for smaller organizations.3

For Gartner, AI has morphed into a clearer category with various subcategories, including AI-enabled vision systems, composite AI, and next-generation humanoid working robots. IoT, meanwhile, has a newly minted category called machine customers. Gartner also pointed to several trends around protection and control of the supply chain, including cyber extortion, supply chain data governance, and end-to-end sustainable supply chains (Figure 2).

Figure 2 : Gartner has AI as a clearer category with various subcategories, including AI-enabled vision systems, composite AI, and next-generation humanoid robots. (Image source: Gartner)

Figure 2 : Gartner has AI as a clearer category with various subcategories, including AI-enabled vision systems, composite AI, and next-generation humanoid robots. (Image source: Gartner)

Even smarter AI and IoT

Regarding AI, we’re moving from automation to hyper-automation that utilizes advanced Industrial IoT (IIoT) technology. For example, AI-enabled machine vision systems combine 3D cameras, computer vision (CV) software, and pattern recognition technologies that use advanced AI. As with any emerging technology, this remains a stretch even for large, sophisticated manufacturing operations. These solutions can autonomously capture, interpret, and make inferences based on the real-time unstructured images the vision systems see. The most common uses of machine vision are visual inspection and defect detection, positioning and measuring parts, and identifying, sorting, and tracking products.4

The combination of AI technology and IoT may also have the potential to ease some manufacturer woes, such as workforce skills and labor shortages. Augmented connected workforce (ACWF) initiatives get new employees up to speed more quickly in the use of intelligent technology, workforce analytics, and skills augmentation. Human capabilities and productivity increase as the system provides workers with real-time access to information, enables seamless collaboration, and facilitates immersive training experiences.

Another emerging category is composite AI, which Gartner defines as “the combined application of multiple AI techniques” to solve business problems that can improve supply chain performance. These analytical techniques might include:

- Machine learning (ML) / deep learning (DL)

- Natural language processing (NLP)

- CV

- Descriptive statistics

- Knowledge graphs

However, it remains to be seen how broadly applicable this type of technology might be. Organizations must clearly define what performance enhancements are essential for them to be effective. For now, there is no one-size-fits-all solution for applying composite AI.

At least one identified trend is already widely used today: machine customers. These non-human actors can autonomously obtain goods and services in exchange for payment. According to another Gartner report, about 13 billion IoT products are deployed and can act as customers.5 Often, this technology is most useful for inexpensive and widely used parts (think capacitors or resistors) rather than those specifically designed for a new product.

Safety and governance

As the supply chain becomes more technologically advanced, it makes sense that data safety and governance will rise in importance. The same AI technology that will help the future of the supply chain will also likely be in the cybercriminals' arsenal. AI can potentially create sophisticated malware and ransomware to attack unsuspecting supply chains.

For the last five quarters, the Lehigh Business Supply Chain Risk Management Index put cybersecurity at the top of its list as the most significant risk on supply chain managers’ minds (Figure 3). It has increased by more than 5.5 points from last quarter, putting it 12 points above the average. The 3rd quarter of 2024 saw a slight decline, but concern remained high. Risks include cyberattacks, data corruption, data theft, system viruses, and security platform controls.6 Organizations will have to work closely with their IT function to stay ahead of the cybercriminals.

Figure 3: Cybersecurity and data risk takes the top spot in the Lehigh Business Supply Chain Risk Management Index by a large margin, putting it 12 points above the average. (Image source: Lehigh Business Supply Chain Risk Management Index)

Figure 3: Cybersecurity and data risk takes the top spot in the Lehigh Business Supply Chain Risk Management Index by a large margin, putting it 12 points above the average. (Image source: Lehigh Business Supply Chain Risk Management Index)

Governance and sustainability, meanwhile, are supported by AI and analytics. Organizations can use innovative technology to increase cross-functional visibility, scenario modeling, and decision automation. Data accuracy is critical for both areas, as poor data leads to poor results.

AI may finally be coming into its own in the supply chain, and 2024 is likely to see a sharp focus on implementing AI-supported technologies across it. As the technology in the supply chain advances, data accuracy will only become more critical.

References

1: https://www.researchandmarkets.com/reports/5232515/supply-chain-management-scm-software-global

2: https://www.gartner.com/smarterwithgartner/gartner-top-8-supply-chain-technology-trends-for-2019

4: https://www.intel.com/content/www/us/en/manufacturing/what-is-machine-vision.html

6: https://business.lehigh.edu/sites/default/files/2024-06/LRMI_2024_3rd_Quarter_Report_final2.pdf

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum