Optimizing Remote I/O for Efficiency, Maintainability, and Adaptability

For remote input/output (I/O) systems, efficiency is everything. The notion of remote I/O first arose because industrial operations needed a more efficient way to connect programmable logic controllers (PLCs) to their equipment. Rather than running long wires to every sensor and actuator, remote I/O cabinets consolidated these connections near the equipment, with all data shipped to the PLC over a shared, plant-wide network.

Today, the demand for greater efficiency has expanded. Designers need more I/O packed into a smaller footprint to compete effectively. They are looking for ways to streamline I/O system design, installation, and maintenance; and they are seeking solutions with adaptability as their needs change.

You can track the evolution of these requirements in the history of the I/O System IP20 u-remote system from Weidmüller (Figure 1). First introduced in 2013, u-remote prioritizes efficiency in every sense of the word, starting with I/O modules that are just 11.5 millimeters (mm) wide. These remarkably narrow modules minimize the cabinet space required for a remote I/O system.

Figure 1: The I/O System IP20 u-remote modules are extraordinarily narrow, keeping their footprint to a minimum. (Image source: Weidmüller)

Figure 1: The I/O System IP20 u-remote modules are extraordinarily narrow, keeping their footprint to a minimum. (Image source: Weidmüller)

Modules that are easy to deploy and maintain

The modules are also efficient in terms of worker productivity. Each pluggable module is connected to the rest of the I/O system by simply snapping it into place. No backplane or external wiring is required. Instead, all power and data are routed through connectors built into the modules (Figure 2).

Figure 2: The I/O System IP20 u-remote modules use a pluggable design that connects directly without a backplane. (Image source: Weidmüller)

Figure 2: The I/O System IP20 u-remote modules use a pluggable design that connects directly without a backplane. (Image source: Weidmüller)

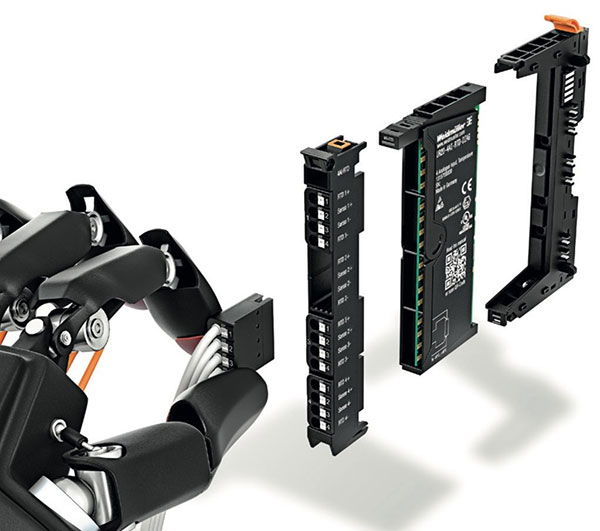

The pluggable design also streamlines maintenance and simplifies upgrades. The modules can be readily added or removed to perform repairs or change system functionality. In fact, many maintenance tasks can be completed without removing a module thanks to their three-part design, which consists of the:

- Connection strip: Allows for the physical connection of the wires from sensors and actuators

- Electronics section: Houses the circuitry responsible for processing the signals from the connected devices

- Base: Enables mounting on a DIN rail and provides electrical connectivity between the modules

This modularity allows for hot-swap replacement of the electronics without interrupting the other modules’ functions or disturbing the module's wiring under maintenance. A removal lever built into the electronics section makes all this possible without any tools (Figure 3).

Figure 3: The I/O modules comprise a connection strip, electronics, and base module. (Image source: Weidmüller)

Figure 3: The I/O modules comprise a connection strip, electronics, and base module. (Image source: Weidmüller)

In 2014, Weidmüller introduced high-density modules that doubled the number of conductors per module to 32. For example, the compact UR20-PG0.35 connecting plug allows up to eight, four-wire sensor inputs to be connected to each module.

The company has since introduced a wide variety of modules. One notable example is the UR20-PF-O-2DI-DELAY-SIL, a safety module introduced in 2015. This SIL 3-compliant module provides emergency stop circuits and short-circuit detection functions. Other types of modules include the:

- UR20-4AI-UI-12, with four analog sensor inputs and an accuracy of 0.1% full-scale range (FSR)

- UR20-4AO-UI-16, with four analog outputs to control up to four actuators with an accuracy of 0.05% of the measurement-range end value

- UR20-16DI-P, with up to 16 digital inputs with a maximum frequency of 1 kilohertz (kHz)

- UR20-8DO-P, which can drive up to eight digital output channels at up to 500 milliamperes (mA) each

Specialized I/O options include the UR20-2CNT-100, which has two independent 32-bit, 100 kHz counters, and the UR20-2PWM-PN-0.5A, which drives two pulse width modulation (PWM) outputs at up to 40 kHz.

Fieldbus connectivity and software intelligence

Beyond I/O consolidation, an essential function of remote I/O systems is to connect to the plant network. With u-remote, this is done with a fieldbus coupler. These couplers are available for most popular fieldbus protocols. For example, the UR20-FBC-PN-ECO supports PROFINET RT, while the UR20-FBC-EC offers Ethernet and EtherCAT networking.

Each fieldbus coupler also provides an integrated web server. This integrated server enables fast error identification with plain-text diagnostics, allowing for faster start-up and shorter downtime. The servers also enable operators to monitor and maintain the system throughout its lifetime. For example, the web servers can simulate inputs and outputs. This feature is handy for testing, enabling users to verify the station’s behavior without physically interacting with the connected devices.

Like the modules, Weidmüller has continued to expand the fieldbus coupler lineup over the years. Today, eleven of the most popular protocols are supported.

Conclusion

As industrial operations continue requiring greater efficiency, remote I/O systems must adapt. The Weidmüller u-remote IP20 system exemplifies this evolution. Starting with a basis of ultra-slim I/O modules, the system has expanded its capabilities over the years, adding support for new I/O and fieldbus options. Its modular design requires minimal tooling and brings efficiency to remote I/O system design, deployment, maintenance, and upgrades.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum