Meeting the Demanding Requirements for Y1 Safety Capacitors

Don't plan on any slack when selecting safety capacitors for high-voltage line-to-ground applications. The international standard is complex and stringent regarding testing and certification of the safety performance for Y1-type safety capacitors, and other fixed capacitors primarily used in AC mains-connected circuits.

The IEC 60384-14 standard is widely adopted or adapted into national regulations worldwide. It specifies requirements for capacitors used for line-to-line (X Class) and line-to-ground (Y Class) applications. Each category has additional sub-classes, and Y1 is specific for user safety and electromagnetic interference (EMI) suppression.

Safety is the paramount concern of the Y1-type standard, and capacitors must be designed to fail safely to prevent catastrophic failures. They are used widely in consumer electronics, such as major appliances, smart home devices, HVAC systems, medical equipment, and industrial control systems.

Y1-type capacitors must be able to withstand impulse voltages up to 8 kV, most commonly in switched power supplies and other applications requiring ground isolation.

That's why it is critical for designers to select the right pre-certified safety capacitors based on voltage ratings, capacitance values, environmental factors, and application-specific requirements. Additionally, the placement of Y1 capacitors on a printed circuit board (PCB) can significantly impact performance and EMI suppression capabilities. It is highly advised to follow best practices to ensure optimal capacitor placement for maximum effectiveness.

Rigorous testing requirements

Using pre-certified Y1-type capacitors ensures they have undergone the required rigorous testing procedures and can withstand surges, operate reliably, and fail safely. They are also designed to withstand harsh environmental conditions, including vibration and extreme temperatures.

The capacitors undergo testing for dielectric strength, capacitance and energy loss, current leakage, temperature stability, humidity resistance, and thermal shock. They also are subjected to long-term voltage stress, high-voltage transients, flammability, vibration, and shock.

Testing is monitored and certified by independent organizations such as Underwriters Laboratories in the U.S. and similar bodies in other regions. Manufacturers are required to provide complete documentation of testing results, material specifications, and production records during audits by certification organizations. Upon certification, they may be monitored by market surveillance authorities such as the U.S. Consumer Product Safety Commission.

Non-compliance with standard and certification rules can result in the withdrawal of certification labeling, financial penalties, product recalls, and even market bans.

Y1 dielectric choices

Y1 safety capacitors utilize either ceramic or polymer film materials for dielectric insulation and energy storage. The type of material affects performance, including capacitance and thermal stability.

Ceramic-based capacitors typically offer a lower capacitance in the range of picofarads (pF) to low nanofarads (nF), provide high-frequency EMI suppression where lower capacitance is acceptable, and are generally available in more compact sizes. That makes them suited for applications such as switch-mode power supplies, automotive circuits, LED drivers, and a growing range of consumer devices.

Film-based capacitors support a wider capacitance range from nF to a microfarad (µF) or more, and are widely employed for applications featuring higher energy storage or filtering at lower frequencies. Being larger and bulkier, they are commonly used where size is a less critical factor, such as industrial and high-power applications.

Murata Electronics’ ceramic DK1 series

With product vendors rolling out smaller devices, capacitors must also evolve to maintain high performance in smaller footprints. Murata Electronics offers a line of Y1 ceramic, surface-mount safety capacitors designed for low-profile, compact AC/DC switch-mode power supply applications.

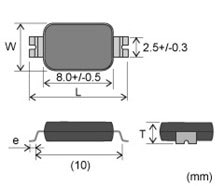

With dimensions of 11.4 mm x 6 mm and a height of only 2.5 mm, Murata's DK1 series of ceramic Y1 capacitors provides designers with an opportunity to contribute to lower-profile power supply applications (Figure 1). Despite the compact nature of these components, they provide capacitance values ranging from 10 pF to 1500 pF, with available Y1-rated voltages from 250 VAC(RMS) to 500 VAC(RMS).

Figure 1: Murata DK1 series Y1 capacitors provide designers with a low-profile, compact surface-mount option (L = 11.4 mm, W = 6 mm, and T = 2.5 mm). (Image source: Murata Electronics)

Figure 1: Murata DK1 series Y1 capacitors provide designers with a low-profile, compact surface-mount option (L = 11.4 mm, W = 6 mm, and T = 2.5 mm). (Image source: Murata Electronics)

The DK1 series devices are tested for long-term reliability under high-stress conditions. They provide superior resistance to heat, moisture, and electrical stress. They operate in a usable temperature range of -40°C to +125°C. Their high insulation resistance, more than 6000 megaohms (MΩ), ensures stability and safety in power supplies, industrial controls, and medical devices.

DK1 series Y capacitors can also be used as Class X capacitors to provide an added safety margin, delivering a higher surge factor than the up to 4 kV of X1 and up to 2.5 kV of X2 capacitors. A capacitor certified for Y1 and X1/X2 can ease design and inventory management challenges in global markets. However, designers should evaluate cost, capacitance requirements, and certifications to ensure dual-certified safety capacitors are the right choice for the application.

Murata's DK1 series provides a wide range of options that offer versatility across consumer electronics, industrial equipment, and other space-constrained designs requiring robust safety features. The following capacitors demonstrate that range:

- The DK1B3EA101K86HAH01 (Figure 2) features a low capacitance of 100 pF with a 300 VAC rating, making it a good option for filtering high-frequency EMI without impacting circuit performance in applications such as signal processing circuits, and high-speed data and communications equipment.

- The DK1E3EA102M86HAH01 provides a capacitance of 1000 pF and a rated voltage of 400 VAC. It is best suited for applications requiring moderate to high EMI suppression, wide-frequency filtering, and resilience in high-voltage or industrial-grade environments.

- The DK1B3EA471K86RAH01 offers a balance of higher noise suppression and safety, with a capacitance of 470 pF. It is suitable for applications requiring both noise filtering and voltage stability, such as AC/DC power supplies for industrial equipment and consumer appliances with motors. It also has a 300 VAC rating.

Figure 2: The low capacitance of Murata's DK1B3EA101K86HAH01 provides EMI filtering without impacting performance. (Image source: Murata Electronics)

Figure 2: The low capacitance of Murata's DK1B3EA101K86HAH01 provides EMI filtering without impacting performance. (Image source: Murata Electronics)

Conclusion

Y1 safety capacitors are crucial for high-voltage applications and undergo rigorous testing to ensure they can withstand impulse voltages, operate reliably, and fail safely in various applications with harsh environmental conditions. Murata Electronics’ DK1 series of ceramic Y1 capacitors offers a compact and low-profile solution for designers in a versatile range of capacitance values and voltage ratings.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum