MEAN WELL's LOP Series Simplifies Power Design

Power supplies are crucial to system performance, but designers often struggle to balance trade-offs such as form factor, power density, efficiency, and certifications. It often seems like an inevitable compromise. This is when it makes sense to consider MEAN WELL options that don't require compromising design goals to fit the bill of materials budget.

With applications increasingly requiring sleek designs, it can be challenging to achieve performance requirements. Many power supplies, especially generic offerings, can turn out to be unreliable, poorly ventilated, and missing safety approvals.

MEAN WELL's LOP series of AC-DC converters offers an attractive balance of cost, size, performance, and global compliance. Designers get the flexibility of an open-frame layout in a low-profile form factor that’s also compatible with printed circuit board (PCB)-style integration.

Power supplies have an outsized impact on thermal performance, form factor, regulatory compliance, and long-term reliability. Choosing the wrong one can create more headaches than it solves, and in areas such as medical devices and industrial equipment, there's little margin for error.

Product designers face a familiar set of challenges in powering their applications. Space is often the primary constraint. Designers seek out low-profile solutions that don’t compromise on power output. They must also manage heat output, often without forced air cooling. Electromagnetic interference (EMI) is another hurdle, in which compliance with emissions and immunity testing can be compromised by power supply harmonics and switching noise. Additionally, shipping products globally requires AC input compatibility and achieving multiple safety certifications.

Low profile, high efficiency

MEAN WELL's LOP family spans 200 W to 600 W, with output voltages ranging from 12 V to 54 V, supporting mid- to high-power applications such as motors, LED lighting, actuators, and industrial control systems.

Designed with the needs of system integrators and product engineers in mind, the LOP series combines a low-profile form factor—as thin as 25.4 mm—with high efficiency (up to 94%), making it suitable for compact, sealed, or fanless designs.

All LOP models support fanless operation via convection cooling, though at derated power levels due to thermal constraints. To reach full rated output, forced-air cooling is required, generally at ≥10 – 23 CFM airflow, depending on the model. Derated fanless output also varies by model.

With universal 85–264 VAC input, built-in protections, and full safety certifications (including IEC/EN/UL62368-1, 60601-1, 61558-1, and 60335-1), the LOP series helps streamline compliance and simplify global deployment.

A wide operating temperature range of -40°C to +80°C and compliance with OVCIII, 2xMOPP, and BF medical application standards make them versatile for use in diverse industries. A broad voltage range spanning 12 V to 54 V and robust safety features make them suitable for Class I and II systems, with applications spanning communication, network, medical, industrial control, security, and home automation.

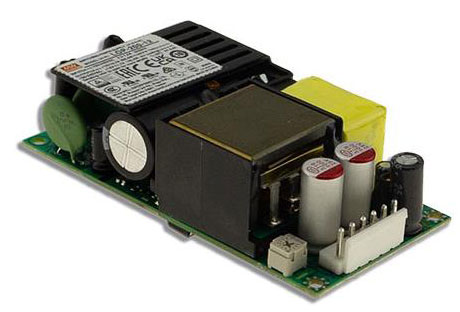

The product line starts with the LOP-200-12: a 200 W, 12 V unit in a compact open-frame package measuring 4.00 in. L x 2.00 in. W x 1.00 in. H (101.6 mm x 50.8 mm x 25.4 mm) (Figure 1). It’s a strong fit for space-constrained applications like LED lighting, control panels, or access systems, where reliability and simplicity are key. LOP-200 models deliver derated power of 140 W when implemented with fanless convection cooling, or the full 200 W with forced air.

Figure 1: The LOP-200 and LOP-300 share a form factor of 4.00 in. x 2.00 in. by 1.00 in. (Image source: MEAN WELL)

Figure 1: The LOP-200 and LOP-300 share a form factor of 4.00 in. x 2.00 in. by 1.00 in. (Image source: MEAN WELL)

LP-300 models share the dimensions of the LOP-200, so designers can upgrade application power levels without retooling enclosures or PCB layout. The LOP-300-12 delivers up to 200 W in fanless implementations and 300 W with forced air cooling.

Three higher-power LOP model lines share a common footprint of 5.00 in. x 3.00 in., with modest increases in height at each step up in power.

With a height of 1.08 in. (27.5 mm), LOP-400 models (Figure 2) support 280 to 320 W with convection cooling. With forced-air cooling, these models deliver the full 400 W output, making them suitable for industrial control systems, motion applications, and power-hungry embedded platforms with active thermal management.

Figure 2: The LOP-400 models measure 3.00 in. by 5.00 in. with a height of 1.08 in. (Image source: MEAN WELL)

Figure 2: The LOP-400 models measure 3.00 in. by 5.00 in. with a height of 1.08 in. (Image source: MEAN WELL)

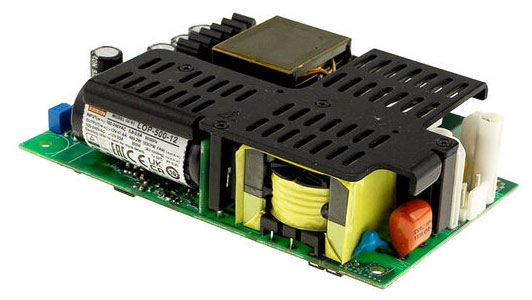

LOP-500 models (Figure 3) have a height of 1.20 in. (30.5 mm) and extend the output capacity up to 500 W. They support convection-cooled operation from 350 W to 400 W. Designers can create semi-passive designs that ramp up fan speed as needed.

Figure 3: LOP-500 power supplies occupy the same board space as the LOP-400, with slightly greater height. (Image source: MEAN WELL)

Figure 3: LOP-500 power supplies occupy the same board space as the LOP-400, with slightly greater height. (Image source: MEAN WELL)

At the top of the power hierarchy, LOP-600 models are geared to fully ventilated environments requiring sustained high power. While they can support fanless operation up to 400 W, achieving the full 600 watt output requires approximately 23 CFM of forced-air cooling. These models are ideal for high-density industrial, automation, or instrumentation systems where thermal management and reliability are critical. The LOP-600-12 has a height of 35 mm, while all other voltage variants measure 33.5 mm in height.

Conclusion

MEAN WELL's LOP series power supplies offer versatility, reliability, and safety for a wide range of demanding applications. With models supporting both fanless convection and forced-air cooling, designers can balance space, noise, and power requirements. The modular design, broad input and output ranges, and comprehensive safety certifications simplify integration for global markets.

Have questions or comments? Continue the conversation on TechForum, DigiKey's online community and technical resource.

Visit TechForum